Основное руководство по выбору лучшего автомата для производства конфет Gummy для вашего бизнеса

Введение в производство гумми

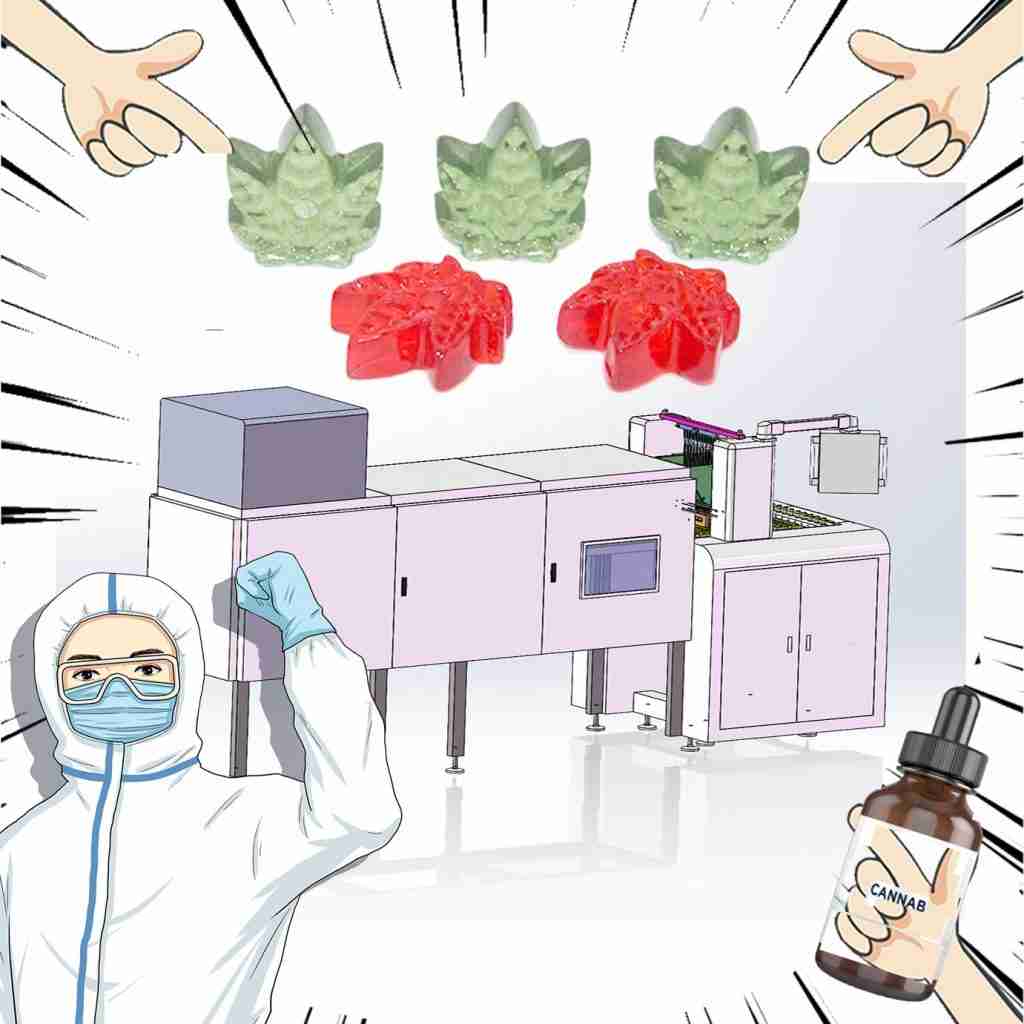

- Производство жевательных конфет включает в себя создание жевательных конфет различных форм, размеров и вкусов с использованием автоматы с жевательными конфетами и кондитерское оборудование. Такие ключевые ингредиенты, как желатин и сахар, необходимы для получения желаемой текстуры и вкуса жевательных конфет.

- Машина для производства жевательных конфет - важнейшая часть производственного процесса, позволяющая выпускать широкий ассортимент жевательных конфет, в том числе с различными вкусами, таких как мишки, червячки и другие жевательные конфеты.

- Понимание различных типов оборудования для производства гумми и их производственных мощностей необходимо для предприятий, собирающихся инвестировать в оборудование для производства гумми. Существуют различные модели оборудования для производства гумми, отвечающие конкретным потребностям бизнеса.

- Оборудование для производства жевательной резинки может быть настроено в соответствии с конкретными производственными спецификациями, обеспечивая беспрепятственную интеграцию с существующим оборудованием. Инновации в оборудовании для производства гумми позволяют создавать индивидуальные решения и уникальные продукты.

Оборудование для производства жевательной резинки

- Аппараты для производства конфет Gummy Предназначены для автоматизации процесса производства жевательных конфет, включая смешивание, нагрев и заливку желейной смеси в формы для жевательных конфет, где машины точно заполняют формы для обеспечения качества продукции и сокращения отходов.

- Система смешивания и нагревательная кастрюля являются важнейшими компонентами машины для производства жевательных конфет, обеспечивающими производство высококачественных жевательных конфет с желаемой текстурой готовых жевательных конфет.

- Гибкие силиконовые формы используются для создания различных форм и размеров жевательных конфет, от жевательных мишек до жевательных змей. Вспомогательное оборудование обеспечивает бесперебойную работу и обслуживание.

- Оборудование для производства жевательной резинки может быть разработано для производства широкого спектра вкусов и текстур, удовлетворяя различные потребности рынка, а различные машины обеспечивают различные производственные мощности и требования.

Выбор правильной машины для производства жевательных резинок

При выборе машины для производства жевательных конфет предприятия должны учитывать такие факторы, как производственная мощность, производственные характеристики и тип жевательных конфет, которые они хотят производить.

Оборудование для производства гумми может быть адаптировано под конкретные нужды, включая производство мишек гумми, червячков гумми и других новых форм гумми.

Оборудование должно быть простым в уходе и обслуживании, с простым и эффективным производственным процессом. Надежные услуги по доставке и установке необходимы для того, чтобы оборудование было доставлено вовремя и правильно настроено для бесперебойного производства.

Предприятия также должны учитывать стоимость машины и потенциальную окупаемость, а также репутацию производителя.

Для получения индивидуальных решений или дополнительных запросов свяжитесь с поставщиком, чтобы обсудить ваши конкретные требования.

Типы оборудования для производства гумми

- Существуют различные типы оборудования для производства гумми, включая мелкие и крупные машины.

- Аппараты для производства конфет Gummy могут быть предназначены как для коммерческих кухонь, так и для крупного промышленного производства, отвечая различным потребностям бизнеса.

- Оборудование может быть настроено на производство конкретных видов жевательных конфет, таких как жевательные мишки или жевательные фрукты.

- Оборудование для производства жевательных конфет также может быть предназначено для производства других видов конфет, например, шоколадных или липких.

Коммерческое использование машин для производства гумми

- Машины для производства жевательных конфет широко используются на коммерческих кухнях и конфетных фабриках для производства высококачественных жевательных конфет.

- Эти машины способны производить большое количество жевательных конфет, что делает их идеальными для предприятий, которым необходимо удовлетворять высокий спрос.

- Автоматы для производства жевательных конфет могут использоваться для производства широкого спектра вкусов и текстур, удовлетворяя различные потребности рынка.

- Оборудование также подходит для производства жевательных конфет для вечеринок, мероприятий и других особых случаев.

Особенности производства мишек Гамми

Когда речь идет о производстве жевательных мишек, выбор правильного автоматы с жевательными конфетами и оборудования для производства жевательных конфет имеет решающее значение для достижения оптимальных результатов. Производители должны оценить несколько факторов, включая желаемую производственную мощность, разнообразие форм и вкусов жевательных мишек, а также консистенцию конечного продукта. Процесс производства обычно включает в себя смешивание желейной смеси, нагрев ее до нужной температуры и заливку в гибкие силиконовые формы, предназначенные для легкого извлечения и очистки. Выбор машины для производства жевательной резинки, позволяющей легко интегрировать ее в существующие производственные линии, позволяет оптимизировать работу и сократить количество отходов. Кроме того, возможность легко разливать смесь в формы различной формы гарантирует, что производители смогут быстро реагировать на изменения рыночного спроса и выпускать широкий ассортимент жевательных конфет. Тщательно изучив эти факторы, производители смогут поддерживать высокие стандарты качества и эффективности, удовлетворяя как производственные спецификации, так и ожидания потребителей.

Преимущества инвестиций в производство жевательных конфет

Инвестиции в производство жевательных конфет открывает безграничные возможности для производителей, желающих расширить ассортимент продукции и выйти на рынок с высоким спросом. Благодаря передовым автоматы с жевательными конфетами и оборудование для производства жевательных конфет позволяют предприятиям эффективно производить жевательные конфеты с различными вкусами, формами и текстурами, удовлетворяя разнообразные потребительские предпочтения. Современное оборудование для производства жевательных конфет позволяет экономить деньги за счет повышения эффективности производства и снижения трудозатрат, что дает возможность производителям поставлять самые свежие сладости по конкурентоспособной цене. Гибкость оборудования для производства жевательных резинок позволяет производителям экспериментировать с различными рецептами и составами, создавая инновационные продукты, которые выделяются на рынке. Если речь идет о поставках на коммерческие кухни, проведении вечеринок или удовлетворении крупномасштабного спроса, правильное оборудование гарантирует последовательность, точность и качество каждой партии. Инвестируя в современное оборудование для производства жевательных резинок, предприятия получают выгоду от повышения эффективности, сокращения отходов и способности быстро адаптироваться к новым тенденциям и потребностям клиентов, что в конечном итоге способствует росту и созданию лояльной клиентской базы.

Обслуживание оборудования для производства гумми

- Для обеспечения долговечности и эффективности оборудования для производства гумми очень важно регулярное техническое обслуживание.

- Оборудование следует регулярно чистить и обслуживать, а при необходимости иметь в наличии запасные части.

- Предприятиям также следует учитывать риск загрязнения и принимать меры по его предотвращению, например, использовать материалы пищевого класса и соблюдать надлежащие процедуры очистки.

- Правильное техническое обслуживание помогает предотвратить отходы и снизить риск поломки оборудования, экономя деньги и обеспечивая бесперебойный производственный процесс.