Незаменимый путеводитель по Линия по производству печенья Настройка и эксплуатация

Введение в производство бисквита

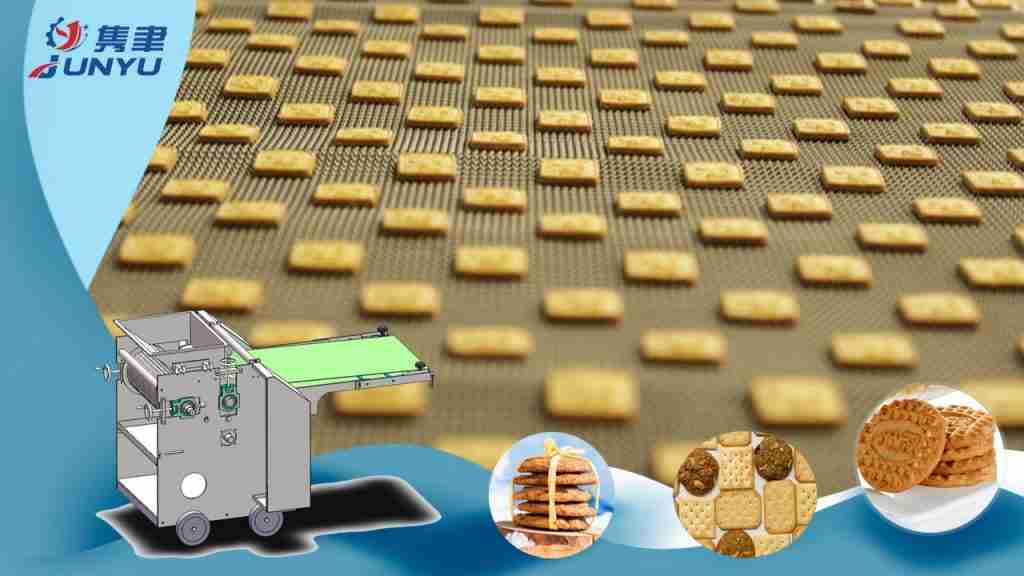

То линия по производству печенья является важнейшей частью пищевой промышленности, позволяя производить печенье с неизменным качеством в массовом масштабе.

Линия по производству печенья состоит из ряда основных этапов и оборудования, начиная со смешивания ингредиентов, таких как мука, жиры и сахар, и заканчивая формовкой, выпечкой и упаковкой печенья. Машины автоматизируют каждый этап процесса, чтобы обеспечить эффективность, последовательность и качество.

Процесс производства печенья включает в себя несколько этапов - от замеса и формирования теста (где сахар является ключевым ингредиентом, влияющим на текстуру и качество) до выпечки и упаковки, что требует применения специализированных машин и оборудования для производства печенья.

Компания может предложить индивидуальные решения по производству бисквита и вспомогательные услуги. Ведущие производители отрасли предлагают самые современные технологии. производственные линии для обеспечения высокого качества печенья и эффективное производство.

Основные компоненты линий для производства бисквита

- Типичный Линия по производству печенья включает в себя тестомес, туннельную печь и конвейерную ленту, которые работают вместе для производства печенья с неизменным качеством и большим объемом. Выбор правильного оборудования необходим для соответствия конкретным видам печенья и производственным потребностям, обеспечивая оптимальные результаты для вашего бизнеса.

- Для получения бисквитов из мягкого теста требуется специальное оборудование, например, миксер для мягкого теста и туннельная печь с точным контролем температуры, чтобы обеспечить желаемую текстуру и качество.

- С другой стороны, для твердого печенья необходим тестомес и туннельная печь с различными температурными режимами, что позволяет настроить линию в соответствии с вашими уникальными производственными потребностями.

- Для повышения производительности в производственную линию может быть интегрировано дополнительное оборудование, например, линии по производству печенья и крекерные машины. Возможны варианты персонализации, позволяющие предприятиям адаптировать производственную линию к своим специфическим требованиям.

Полная настройка линии

Установка полного линия по производству печенья требует тщательного планирования и учета производственных требований, включая производственные мощности и типы печенья. Комплексные линии предлагают интегрированные комплексные решения, которые повышают эффективность, качество продукции и масштабируемость на всех этапах производства.

Производственная линия должна быть спроектирована таким образом, чтобы минимизировать ручной труд и сократить количество отходов, обеспечивая при этом стабильное качество продукции.

Автоматизированные системы и системы управления могут быть внедрены для оптимизации эффективности производства и снижения трудозатрат. Комплектные линии также способствуют повышению эффективности затрат за счет сокращения отходов и оптимизации использования ресурсов, что приводит к долгосрочной экономии.

Производственная линия также должна быть рассчитана на изготовление различных видов печенья, включая мягкое, твердое и сэндвичное.

Производство крекинга

Производство крекеров - это отдельный сегмент пищевой промышленности, требующий специальной производственной линии, разработанной специально для уникальных характеристик крекеров. Процесс производства крекеров начинается с точного замеса теста, затем следует раскатка и резка для получения крекеров нужной формы и размера. Ключевыми компонентами линий по производству крекеров являются туннельные печи, обеспечивающие равномерное пропекание и стабильное качество продукции, и конвейерные ленты, способствующие беспрепятственному прохождению каждого этапа производства. Ведущие производители предлагают самые современные линии для производства крекеров, разработанные с учетом конкретных производственных требований, что позволяет компаниям эффективно выпускать широкий ассортимент крекеров. Инвестируя в современные машины и автоматизированные системы, компании могут значительно повысить эффективность производства, снизить трудозатраты и поддерживать высокое качество продукции на протяжении всего процесса выпечки. Такой подход позволяет не только поддерживать крупномасштабное производство, но и быстро реагировать на меняющиеся требования и тенденции рынка.

Твердые бисквиты и тесто

Производство твердого печенья, такого как крекеры и сухарики, включает в себя специализированный производственный процесс, который начинается с приготовления твердого теста. Такое тесто обычно содержит большее количество воды и тщательно вымешивается для достижения нужной консистенции. Производственная линия для изготовления твердого печенья включает в себя машины для замеса, раскатки и нарезки теста, а затем выпечки в туннельных печах, откалиброванных с учетом специфических требований к твердому тесту. Этот процесс требует точного контроля над такими факторами, как температура теста, влажность и давление, оказываемое при раскатке и резке. Время и температура выпечки также имеют решающее значение для того, чтобы печенье приобрело свою фирменную хрустящую текстуру. Для обработки и упаковки этих деликатных продуктов используется специализированное оборудование, позволяющее свести к минимуму поломки и сохранить качество. Оптимизируя каждый этап производственного процесса, компании могут стабильно производить высококачественное твердое печенье, отвечающее отраслевым стандартам и ожиданиям потребителей.

Изготовление и производство печенья

Изготовление и производство бисквита включает в себя ряд тщательно скоординированных этапов, каждый из которых поддерживается специализированным оборудованием в рамках производственной линии. Процесс обычно начинается с работы тестомеса, который смешивает сырьевые ингредиенты для получения бисквитного теста нужной консистенции и текстуры. Затем тесто передается в раскаточную машину, где оно раскатывается до необходимой толщины, а затем разрезается на формы с помощью резательной машины. Затем сформированные тестовые заготовки выпекаются в туннельной печи, что обеспечивает равномерное пропекание и стабильное качество продукции. Наконец, выпеченное печенье охлаждается и упаковывается с помощью автоматизированного оборудования. Следуя пошаговому руководству и инвестируя в правильные машины и оборудование, компании могут рационализировать процесс производства печенья, сократить количество человеческих ошибок и эффективно производить широкий ассортимент бисквитной продукции. Для обеспечения бесперебойной работы и высокого качества продукции на всей производственной линии необходимы правильное обучение и техническое обслуживание.

Вопросы крупномасштабного производства

- Для крупномасштабного производства печенья требуются специализированные машины и оборудование, в том числе высокопроизводительные тестомесы и туннельные печи.

- Производственная линия должна быть спроектирована таким образом, чтобы обеспечить бесперебойную работу и эффективное производство при минимальном ручном вмешательстве.

- Для обеспечения стабильного качества продукции необходимо осуществлять контроль качества, включая регулярные проверки сырья и готовой продукции.

- Производственная линия также должна быть спроектирована с учетом рыночных тенденций и изменений в производственных требованиях.

Линия по производству печенья Управление

Управление линия по производству печенья Эффективная работа необходима для достижения высокой производительности и стабильного качества продукции. Для этого необходимо контролировать весь производственный процесс, от обработки сырья до конечной упаковки, и обеспечивать бесперебойную работу каждого этапа. Компании могут внедрять автоматизированные системы контроля для наблюдения за производственными линиями в режиме реального времени, быстро выявляя и устраняя любые возникающие проблемы. Меры по контролю качества, такие как регулярные проверки и аудит процессов, помогают поддерживать высокие стандарты и сокращать количество отходов. Методы бережливого производства позволяют оптимизировать рабочие процессы, минимизировать время простоя и повысить общую эффективность производства. Инвестиции в обучение сотрудников гарантируют, что персонал обладает навыками эксплуатации и обслуживания оборудования, устранения неполадок и адаптации к новым технологиям. Сосредоточившись на эффективном управлении производственной линией, компании могут повысить производительность, снизить затраты и стабильно поставлять на рынок высококачественное печенье.

Меры контроля качества

Контроль качества - краеугольный камень успешного производства печенья, гарантирующий, что каждый продукт соответствует строгим стандартам безопасности и качества. На протяжении всего производственного процесса компании должны регулярно тестировать и проверять как сырье, так и готовые бисквиты, чтобы выявить любые отклонения от требуемых спецификаций. Мониторинг производственного процесса с помощью современных машин и систем управления помогает выявить потенциальные проблемы на ранней стадии, что позволяет быстро принять меры по их устранению. Специализированное оборудование, такое как металлодетекторы и рентгеновские аппараты, может быть интегрировано в производственную линию для обнаружения загрязнений и обеспечения безопасности продукции. Обслуживание оборудования и помещений также имеет решающее значение для предотвращения загрязнения и соблюдения санитарных норм. Внедряя комплексные меры контроля качества, компании могут снизить риск отзыва продукции, повысить доверие потребителей и укрепить свою репутацию в конкурентной пищевой промышленности.