Благодаря точному дозированию, быстрой переналадке и удобному управлению эти мини-депозиторы для малых партий идеально подходят для исследований, разработки продукции и тестового маркетинга жевательных конфет, желе, твердых конфет, леденцов, одноцветных продуктов, медицинских продуктов, таких как жевательные добавки, и многого другого. Компактный дизайн оптимизирует пространство, а контактные поверхности SUS316 и рама SUS304 гарантируют гигиеничность и долговечность. Легко масштабируйте производство, получая стабильные результаты и минимальные усилия по настройке. Мини-депозитор для гумми идеально подходит для малых предприятий и стартапов, стремящихся развивать свой кондитерский бизнес. Он поддерживает широкий спектр форм и позволяет настраивать формы, включая различные дизайны гумми и размеры металлических форм в соответствии с конкретными размерами и требованиями к продукту. Ключевые аспекты, которые необходимо учитывать при выборе мини-депозитора для малых партий, включают в себя масштабы производства, размеры продукции, возможность настройки формы и простоту очистки.

Превратите сиропообразную жевательную смесь в идеально дозированных мишек, червячков или жевательные конфеты вашей собственной формы со скоростью 3 000-24 000 штук в час, при этом достаточно компактные, чтобы поместиться на столешнице. Машина может работать с другими диапазонами веса жевательных конфет и конфеты, Поддерживая различные требования к продукции.

| Модель | 20/20s | 30 | 40/40s | 50s |

|---|---|---|---|---|

| Скорость | 10-20pcs/time (Вручную) | 10-20pcs/time (Вручную) | 10-20pcs/time (По цилиндру) 15-20 тим/мин | 20pcs/time (С помощью двигателя) 15-20 тим/мин |

| Размер бункера | 25L | 25L | 30л | 30л |

| Емкость | 3000-6000 шт/ч | 3000-6000 шт/ч | 5000-9000 шт/ч | 18000-24000 шт/ч |

| Тип управления | Панель для ног | Нажмите кнопку Панель | Управление цилиндром | Электрическое управление |

| Тип депозита | Цилиндр/сервопривод | Сервопривод | Цилиндр/сервопривод | Сервопривод |

| Цена | $8xxx | $$10xxx | $1xxx | $1xxx |

Примечание: Скорость депонирования является ключевым показателем для оценки производительности и эффективности производства.

Как выбрать:20-30Модель подходит для лаборатории и научно-исследовательских разработок.

40-50Модель подходит для небольших производств, более автоматических и с меньшими затратами труда.

Модель:20/20Срево лаборатория конфеты депозитор

Производительность: 3000-6000 шт/ч

Насадки: 20 шт.

Размер бункера: 25 л

Скорость: 10-20шт/время По панели ног

Площадь основания: 35” x 35.5”

Складной рабочий стол

Операторы: Требуется 1-2 человека

Модель: 30 Сервоупаковщик конфет

Производительность: 3000-6000 шт/ч

Насадки: 20 шт.

Размер бункера: 25 л

Скорость: 10-20шт/время По панели ног

Площадь: 45” x 35.5”

Функция удаления формочек со сменной формовочной пластиной и выталкивающим штифтом, позволяющая быстро освобождать жевательные конфеты и леденцы.

Операторы: Требуется 1-2 человека

Модель:40/40 Срево машина для отсадки конфет

Производительность: 5000-9000 шт/ч

Насадки: 20 шт.

Объем бункера: 30 л

Скорость: 10-20 шт/время С помощью цилиндра и фотоэлектрического датчика депонирования

Площадь: 105” x 46”

Пневмоцилиндр с пневматическим приводом используется для эффективной обработки пресс-форм и упрощения процесса распалубки.

Операторы: Требуется 1-2 человека

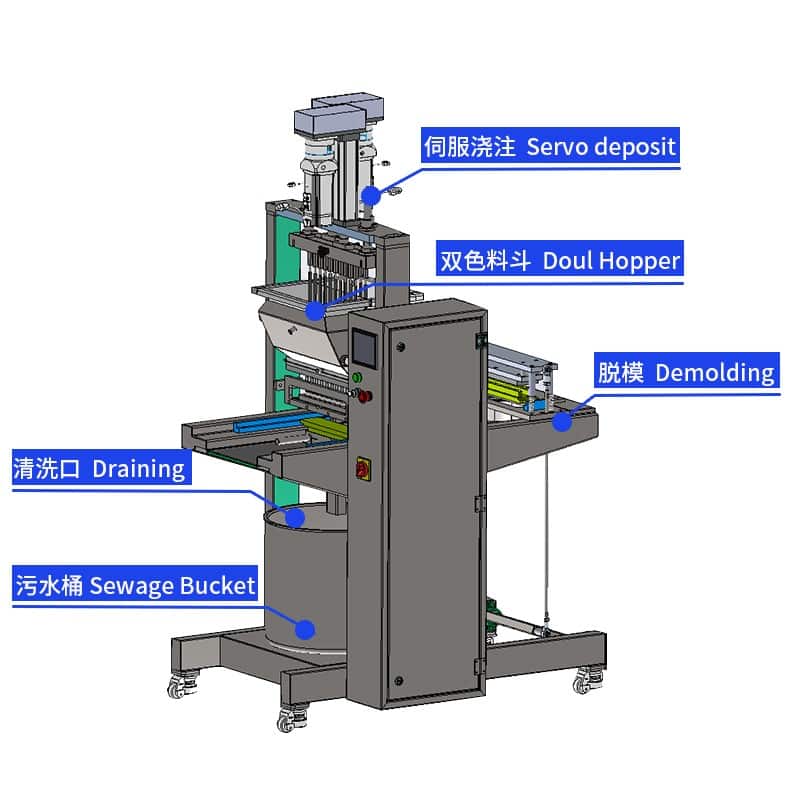

Модель:50Smei-автоматическая машина для осаждения конфет

Производительность: 18000-24000 шт/ч

Насадки: 20 шт.

Объем бункера: 30 л

Скорость: 10-20шт/время формы, закрепленные на цепи и фотоэлектрический датчик депонирования

Площадь: 135” x 46”

Пневмоцилиндр с пневматическим приводом используется для эффективной обработки пресс-форм и упрощения процесса распалубки.

Операторы: Требуется 1-2 человека

Производство жевательной резинки - это специализированный процесс в кондитерской промышленности, включающий в себя широкий спектр продукты, такие как жевательные мишки, Леденцы, леденцы и инновационные жевательные добавки. Достижение одинаковой формы, размера и веса каждого изделия имеет решающее значение как для привлекательности продукта, так и для соблюдения нормативных требований. Для предприятий, работающих в условиях низкопроизводительного производства или только начинающих свою деятельность, точность и эффективность имеют ключевое значение. Именно в таких случаях необходимо использовать мини-депозитор для конфет становится бесценным. Разработанные специально для производства жевательной резинки, эти машины обеспечивают высокую эффективность производства и способны выпускать до 18 000 штук в час даже при небольших партиях. Благодаря своей адаптивности они подходят для различных кондитерских изделий, позволяя предприятиям производить конфеты и жевательные конфеты с точностью и последовательностью, необходимыми для успеха на современном конкурентном рынке.

Мини-депозитор для жевательных резинок - это компактное полуавтоматическое решение для точного производства жевательных резинок, шоколада и других кондитерских изделий. Оснащенный удобным сенсорным интерфейсом, оператор может легко настроить и сохранить до 65 рецептов, что обеспечивает гибкость при работе с различными продуктами. При производстве желатиновых или пектиновых жевательных резинок, конфет или шоколада 10 форсунок машины гарантируют равномерное и последовательное дозирование. Двойные настройки температурного контроля дополнительно оптимизируют процесс, адаптируясь к специфическим потребностям каждой партии. Для небольших предприятий, стремящихся к максимальной производительности и поддержанию качества на своей производственной линии, мини-депозитор для гумми является незаменимым оборудованием, сочетающим в себе контроль, эффективность и универсальность.

Мини-депозитор конфет разработан для обеспечения эффективности и адаптации, что делает его разумной инвестицией для предприятий с различными производственными потребностями. Его компактные размеры и полуавтоматический режим работы упрощают производственный процесс, сокращая трудозатраты и время на установку. Точная система дозирования обеспечивает равномерное наполнение, что приводит к неизменному качеству продукции и незначительному количеству брака. Универсальность - еще одно решающее преимущество: депонирующее устройство вмещает различные типы лотков и размеры порций от 1 до 7 граммов, а опциональный второй бункер (емкостью 30 л) позволяет производить продукты с центральным наполнением или многоцветные жевательные конфеты. Такая гибкость обеспечивает быструю смену продукции, помогая предприятиям удовлетворять меняющиеся требования рынка при сохранении высокой эффективности производства.

Помимо производства жевательных конфет, мини-депозитор открывает новые возможности для создания твердых конфет, включая леденцы и ириски. Усовершенствованная система дозирования и точный температурный контроль обеспечивают точное дозирование активных ингредиентов и равномерное наполнение, что очень важно для обеспечения качества и соответствия нормативным требованиям. Использование металлических размеров форм и алюминиевых форм с тефлоновым покрытием позволяет быстро освобождать их и легко перемещать, упрощая процесс распаковки. Способная производить до 5 000 твердых конфет в час, эта машина идеально подходит для мелкосерийного производства, позволяя предприятиям разнообразить ассортимент продукции с минимальными дополнительными инвестициями. Независимо от того, хотите ли вы производить классические леденцы или инновационные ириски, мини-депозитор конфет обеспечит контроль и эффективность, необходимые для успеха.

Интеграция мини встраивание конфетного депо в существующую производственную линию благодаря компактной конструкции и гибким функциям. Конвейерная система транспортировки и система охлаждающих тележек легко интегрируются друг с другом, обеспечивая плавный и эффективный рабочий процесс от внесения до охлаждения. Передовые системы управления PLC и интуитивно понятный экран HMI обеспечивают операторам постоянный контроль и точное дозирование активных ингредиентов, поддерживая стабильное качество продукции в партиях. Способность машины работать с различными типами лотков и адаптироваться к различным производственным потребностям делает ее ценным активом для предприятий, нацеленных на повышение эффективности производства и минимизацию времени наладки. Благодаря этим возможностям мини-депозитор конфет помогает рационализировать операции и поддерживает масштабируемый рост кондитерского производства.