A longevidade de uma máquina de fabricação de balas de gelatina é uma consideração crítica para qualquer empresa de confeitaria que pretenda investir nesse tipo de equipamento. A vida útil desse maquinário pode afetar os custos de produção, a qualidade da produção e a capacidade de atender às demandas do mercado ao longo do tempo.

Este artigo abrangente analisa os fatores que contribuem para a vida útil de uma máquina de fabricação de balas de gelatina, fornecendo insights para que as empresas tomem decisões informadas.

1. Qualidade da construção

O aspecto fundamental da vida útil de uma máquina é a qualidade de sua construção. As máquinas construídas com materiais robustos e de alta qualidade tendem a ter uma vida operacional mais longa do que aquelas feitas com materiais mais baratos e menos duráveis.

2. Reputação do fabricante

A vida útil de uma máquina pode ser um indicativo da reputação de qualidade e confiabilidade do fabricante. Fabricantes estabelecidos com um histórico de produção de equipamentos de longa duração geralmente são um investimento mais seguro.

3. Manutenção e cuidados

A manutenção adequada é fundamental para prolongar a vida útil de uma máquina de fabricação de balas de gelatina. As inspeções regulares, as substituições oportunas de peças e a adesão aos cronogramas de limpeza podem afetar significativamente o tempo de operação da máquina.

4. Frequência de uso

Quanto maior a frequência de uso de uma máquina, maior o desgaste que ela sofrerá. As máquinas em ambientes de produção de alta demanda podem exigir manutenção mais frequente ou substituição de peças para manter sua vida útil.

5. Condições operacionais

As condições em que a máquina opera também podem afetar sua vida útil. Fatores como temperatura, umidade e limpeza do ambiente de produção desempenham um papel importante na durabilidade do maquinário.

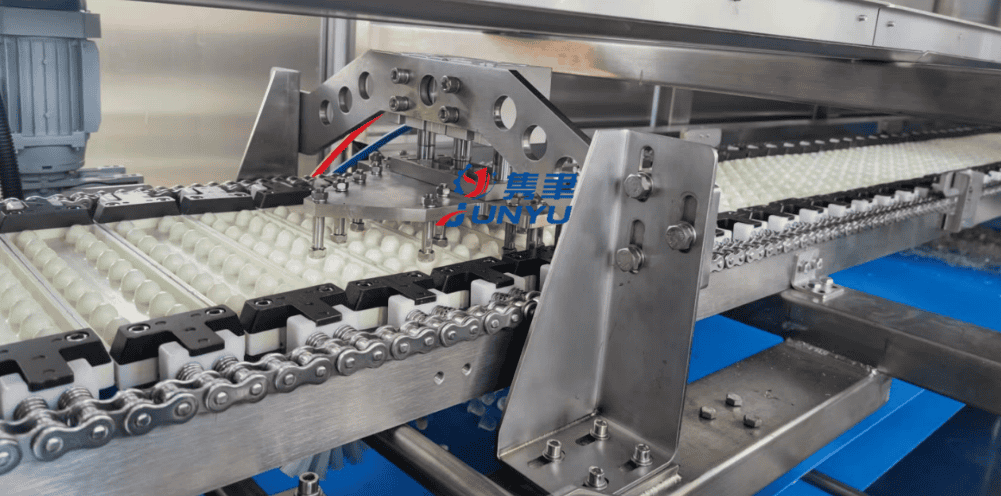

6. Tipo de máquina

Diferentes Tipos de máquinas de fabricação de balas de gelatina têm vida útil variável. Por exemplo, uma prensa manual simples pode durar mais tempo sob uso leve do que uma prensa complexa e completa. linha de produção automatizada.

7. Compatibilidade de materiais

A compatibilidade dos ingredientes da geleia com os materiais da máquina é essencial. Alguns ingredientes podem causar corrosão ou desgaste em determinados metais ou plásticos, exigindo o uso de materiais específicos que possam resistir a esses efeitos.

8. Avanços tecnológicos

Com o avanço da tecnologia, as máquinas mais antigas podem se tornar obsoletas, mesmo que ainda estejam funcionando. Manter uma máquina atualizada com a tecnologia mais recente pode aumentar sua utilidade e vida útil.

9. Atualizações e modernizações

A capacidade de atualizar ou reequipar uma máquina com novos componentes ou tecnologia pode ajudar a prolongar sua vida útil, mantendo-a competitiva em relação aos modelos mais novos.

10. Vida útil econômica

A vida útil econômica de uma máquina é o período em que sua operação permanece econômica. Isso pode ser influenciado por fatores como eficiência energética, rendimento da produção e custo de manutenção.

11. Tempo de vida físico

A vida útil física refere-se ao tempo em que uma máquina pode operar sem avarias ou reparos significativos. Isso geralmente é determinado pela qualidade da construção e pelo desgaste das peças móveis.

12. Conformidade legal e regulatória

Mudanças regulatórias podem exigir atualizações nas máquinas para atender a novos padrões de segurança ou produção, o que pode afetar a vida útil operacional de uma máquina.

13. Demanda do mercado

A demanda por determinados tipos de balas de gelatina pode mudar com o tempo, afetando a necessidade de máquinas específicas. Uma máquina que produz um produto popular hoje pode se tornar menos relevante amanhã.

14. Treinamento de operadores

Operadores bem treinados que sabem como usar e manter a máquina adequadamente podem ajudar a prolongar sua vida útil, reduzindo o risco de erros do operador e danos acidentais.

15. Serviços de reparo e suporte

Acesso a reparos e suporte de qualidade serviços pode ajudar a manter a vida útil de uma máquina, fornecendo reparos e substituições de peças em tempo hábil.

16. Disponibilidade de peças

A disponibilidade de peças de reposição é fundamental para prolongar a vida útil de uma máquina. Os fabricantes que oferecem suporte de longo prazo e estoque de peças têm maior probabilidade de manter uma máquina operacional.

17. Eficiência energética

Eficiência energética As máquinas não apenas reduzem os custos operacionais mas também pode ser projetado com componentes que duram mais, contribuindo para uma vida útil mais longa.

18. Obsolescência e ciclos de substituição

O conceito de obsolescência planejada no setor pode afetar a percepção da vida útil de uma máquina. No entanto, máquinas bem construídas podem durar mais do que os ciclos de substituição planejados.

19. Considerações financeiras

As implicações financeiras de possuir um máquina de fazer doces de gelatina, A escolha de uma máquina é feita com base no custo de propriedade, na manutenção e no tempo de inatividade em potencial, o que influencia a decisão de substituir ou continuar usando uma máquina.

20. Impacto ambiental

O impacto ambiental da fabricação e da operação de uma máquina de fabricação de balas de gelatina pode influenciar sua vida útil, principalmente à medida que mais empresas adotam práticas sustentáveis.

Conclusão

A vida útil de uma máquina de fabricação de balas de gelatina é influenciada por uma série de fatores, desde sua construção inicial e qualidade até a manutenção contínua, atualizações tecnológicas e demandas do mercado. Ao compreender esses fatores, as empresas podem tomar decisões estratégicas sobre o investimento e a manutenção de suas máquinas para garantir uma operação de confeitaria produtiva e econômica. Como acontece com qualquer investimento, a vida útil de uma máquina de confeitaria é muito longa. máquina de fazer doces de gelatina é um equilíbrio entre funcionalidade, custo e a capacidade de se adaptar às mudanças no cenário do setor.