Quem somos

Sobre a Junyu

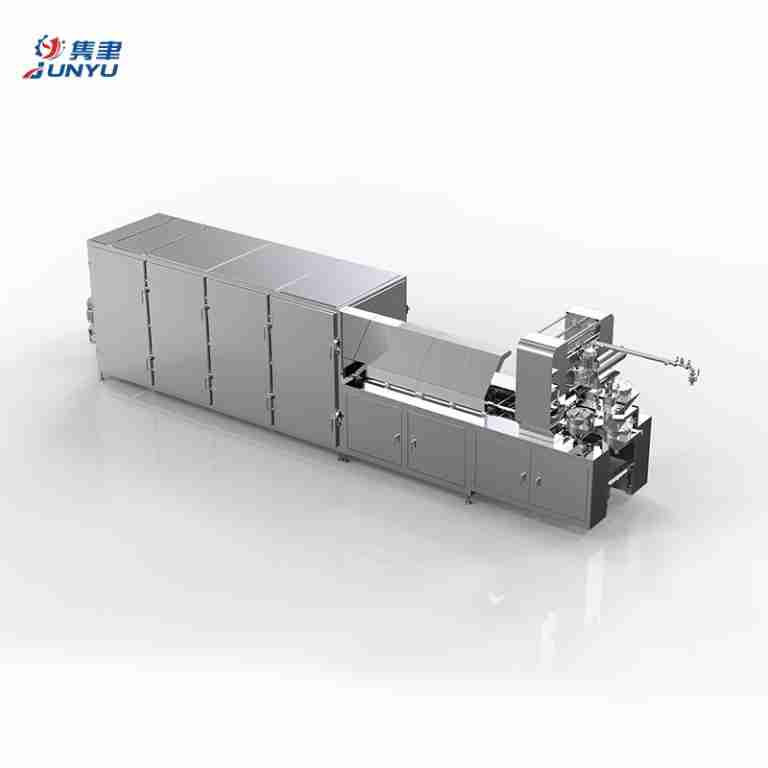

Junyu é um fabricante profissional de equipamentos para alimentos, tais comomáquinas de fabricação de biscoitos, Linha de Produção de Bolo, Candy Gummy, Linha de produção de gomaLinha de produção de biscoitos, equipamentos para salgadinhos e assim por diante. Atuamos nessa linha há mais de 30 anos. Nossos produtos são bem vendidos em todo o mundo e gozam de boa reputação entre nossos clientes.

Nossa empresa foi aprovada na certificação do sistema de gerenciamento de qualidade ISO9001:2008 e também é uma das empresas centrais da China Food Preparation Equipment Industry Association (CFPEA).

Queremos fazer amizade com você por meio de nossos produtos de alta qualidade e serviço sincero.

Categorias de produtos

02.

02. Linha de produção de doces

03.

03. Linha de produção de chocolate

04.

04. Máquina de embalagem de alimentos

05.

05. Linha de produção de boba

06.

06. Linha de produção de bolos

Junyu

Nossos serviços

Fabricação de equipamentos alimentícios de alta qualidade

A Junyu é especializada no projeto e na fabricação de equipamentos de alimentos de primeira linha, incluindo sistemas de gomas para doces, linhas de produção de biscoitos, máquinas para bolos e equipamentos para salgadinhos. Com mais de 30 anos de experiência no setor, garantimos que cada produto que fornecemos atenda aos mais altos padrões de qualidade e eficiência.

Distribuição e reputação globais

Nossos equipamentos para alimentos são confiáveis e vendidos em todo o mundo, o que nos rendeu uma forte reputação de confiabilidade e inovação. Não importa onde você esteja localizado, a Junyu garante que nossos produtos atendam às necessidades dos clientes em diferentes regiões, proporcionando qualidade e desempenho consistentes.

Gestão de qualidade com certificação ISO9001:2008

A Junyu tem o compromisso de manter os mais altos padrões de excelência em fabricação. Desde os equipamentos para gomas de mascar até nossos avançados sistemas de linha de produção de biscoitos, todos os produtos são certificados pelo sistema de gerenciamento de qualidade ISO9001:2008, garantindo precisão artesanal e desempenho duradouro.

Suporte abrangente ao cliente

Nós nos dedicamos a oferecer um atendimento excepcional ao cliente. Desde a consultoria pré-venda até o suporte pós-venda, nossa equipe na Junyu está sempre pronta para ajudá-lo em cada etapa de sua jornada de compra. Se você precisar de assistência técnica ou orientação sobre o uso do produto, estamos aqui para ajudar.

Liderança e colaboração do setor

Como uma das empresas centrais da China Food Preparation Equipment Industry Association (CFPEA), a Junyu desempenha um papel ativo na formação do setor de equipamentos alimentícios. Colaboramos com outros líderes da área para garantir que nossos produtos não sejam apenas inovadores, mas também estejam alinhados com os mais recentes padrões e tendências do setor.

Soluções sob medida para sua empresa

Entendemos que cada empresa tem necessidades exclusivas. A Junyu oferece soluções personalizadas de equipamentos para alimentos, adaptadas às suas necessidades específicas de produção. Se estiver procurando um sistema para balas de goma, uma linha de produção de biscoitos, uma máquina de bolos ou um equipamento para salgadinhos, nossa equipe de especialistas trabalhará com você para criar a solução perfeita para a sua operação.

Junyu

Máquina de goma para doces e máquinas de linha de produção de biscoitos

Operação simples Preço razoável Ajuste de temperatura Depósito servo PLC ajustável...

Ao integrar tecnologia avançada e processos otimizados, essa linha ajuda...

Junyu

Nossos clientes

Junyu

Últimas notícias

O Guia Real para Biscoitos Veganos: Macios, Folhados & 100% à Base de Plantas

- 12345678...910111213141516171819202122232425262728293031323334353637383940414243444546474849505152535455565758596061626364656667686970717273747576777879808182838485868788