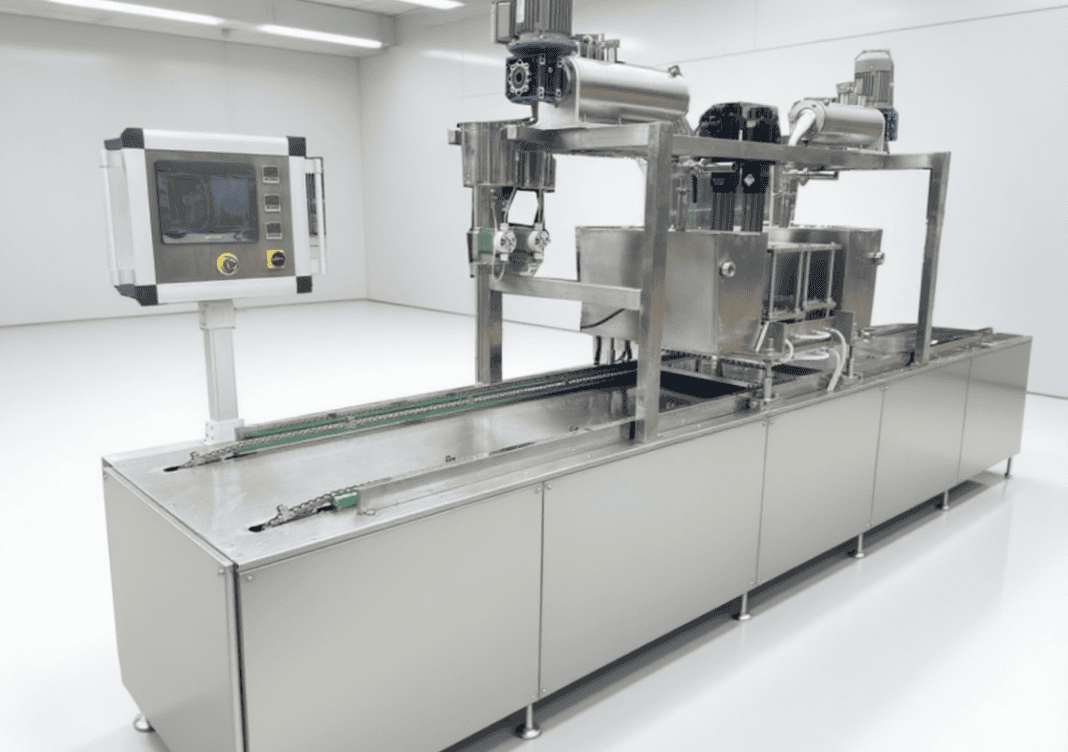

A compact but powerful solution for small-to-medium scale production of starch-based jelly and gummy candies. It keeps the classic starch-mold process while adding partial automation to cut labor, reduce floor space and still deliver uniform, high-quality products. The system is designed for producing different types of candies, including fudge, jelly candy, health products, and producing gelatin base candies. It supports the use of various gelling agents such as carrageenan, agar, and arabic gum, making it suitable for vegetarian and health-oriented options. The versatility of the starch mogul lines allows for a wide range of recipes and market-specific products.

Core Layout

① Cooking Unit – electric or steam jacketed kettle dissolves sugar/glucose/water; PLC keeps ±1 °C accuracy. The kitchen system includes automatic weighing for ingredients, ensuring consistency and efficiency. The kitchen system is responsible for preparing and mixing all raw materials, including syrup and other ingredients, and the process is precisely controlled for quality.

② Semi-Auto Mogul – servo-driven tray conveyor (low-speed brake + high-speed run) deposits 18–22 cycles/min; single or double color, center-filled or layered shapes possible.

③ Starch Conditioning & Recycling – integrated vibrating sieve and air-return reclaim 85 % of starch for immediate reuse, lowering raw-material cost.

④ Curing / Drying – trays stay 2–4 h in a temperature-controlled room; no extra conveyors needed.

⑤ De-starching & Oiling、Sugar sanding – manual discharge station with dust hood and optional sugar/oil coater.

The equipment features a no brush design to enhance hygiene and reduce maintenance. High-quality materials are used for durability and food safety, ensuring a stable run and recipe safe operation for consistent product quality.

Automatic cooking system

Want to take candy production to the next level? Our Automatic Candy Cooking System handles the hard work—so you can focus on innovation.

Engineered for seamless, hands-off operation, it’s a game-changer for scaling production with uncompromising quality. The system supports high sales potential due to its large capacity and reliable operation.

Molds printing and candy deposit

Candy molds -mold printer

Semi Candy Depositor: Flexibility in Every Pour

Need a balance of control and efficiency for your candy production? Our Semi Candy Depositor delivers just that.

Designed to handle the middle ground between manual and full automation, it’s ideal for small to medium batches:

Want to make your candies stand out with unique designs? Our candy molds and mold printer are here to turn ideas into edible art.

For classic needs, our ready-to-use candy molds come in hundreds of shapes—from playful animals to elegant geometric patterns—perfect for consistent, eye-catching treats.

Need something one-of-a-kind? Our mold printer lets you create custom molds in hours. Upload your design, and it prints precise, food-safe molds tailored to your brand, whether it’s a logo, seasonal theme, or signature shape.

Time-saver: Cuts down on manual labor without the complexity of full automation, speeding up output.

Adaptable design: Works for different type of candy recipe—easily adjusts to new recipes as your menu grows.

Whether you’re a boutique brand expanding or a mid-sized operation streamlining, it grows with your needs.

Gummy candy depositing machine

Trays size: 400x400mm / 300x600mm / 400x600mm / 400x800mm / Or customized

| Semi-Automaic Model | JYS-150 | JYJ-300 | JYJ-600 |

|---|---|---|---|

| Tray size(cm) | 40×40 | 40×60 | 40×80 |

| Candy qty(per stork) Depend on candy weight | About 64-180pcs | About 200-300pcs | About 528-720pcs |

| Depositing speed (times/min) | 15-20 | 15-20 | 15-20 |

Active vacuum dust suppression during mold filling/demolding

15% faster starch recycling vs gravity-fed systems

Containment meets OSHA/CE PM2.5 standards

Quick-change molds shapes (hearts, animals, etc.)

Single color or double color or center filling

40% lower power consumption than full-auto lines

Sapce require lower than the automatic lines.

Wide voltage compatibility (110-440V) for global operation

Revolutionary Dust-Free Production with Vacuum TechnologyEngineered for gummies, jelly candies & starch-molded confections.

Features integrated vacuum powder suction system that: Reduces footprint by 35% vs traditional dusting systems Cuts airborne dust by 90% (tested per ISO 14644-1) Eliminates secondary cleaning costsFull-process automation from mixing to drying, achieving 80-150kg/batch capacity with semi-opertional flexibility.

Feature highlights:

Want to give your candies that perfect sugary finish? Our Sugar Sanding Machine is the answer.

Designed to evenly coat candies with sugar, it’s a must-have for making your treats look as good as they taste:

Key features to compare

• Small commercial: 25–200 kg/batch • High-volume continuous: 800–3 600 kg/h • Material: SS 304/316, food-grade • Heating: electric, gas, steam or hot-air injection • Controls: PLC + touch screen, variable belt/drum speed, steam jets, dust hoods • Cleaning: quick-release drum, reversible discharge, easy-swing sugar hopper

Typical applications • Sugar-coated gummies & jellies • Chocolate-nut dragees (almond, peanut, cashew) • Pharmaceutical tablets & micro-granules • Spiced or flavored nuts and seeds

What it does • Evenly coats gummies, tablets, nuts or candies with sugar, chocolate, spices or oil. • Creates a glossy, matte or “sanded” finish that improves appearance, taste and shelf life.

Main types • Rotary / Pan Coater – classic revolving drum; batch or continuous; 25 kg – 3 600 kg/h • Mini / Lab Coater – 2–40 kg/batch, tabletop, 30 kg footprint • Continuous Coater – inline with mogul lines; steaming + sanding drum, up to 3 600 kg/h

As a leading manufacturer of starch mogul lines in China, we have extensive experience in delivering high-quality, automated solutions for candy production. For more information or support, please contact us via e mail or mail.

The starch mogul is at the heart of any modern gummy candy production line, serving as the foundation for a reliable starch conditioning system. This advanced machine is engineered to seamlessly integrate with a fully automatic production line, making it the go-to solution for manufacturers aiming to produce high-quality gummy candies at scale. Whether your goal is to create classic single-color gummies, innovative center filling gummy, vibrant double color gummy, or even multi layer gummy, the starch mogul line delivers the flexibility and precision you need.

Thanks to its sophisticated design, the starch mogul is suitable for producing a wide variety of confectionery products. From gelatin base candies and pectin based candies to foamed candies, marshmallow, and more, this system adapts to different recipes and production requirements with ease. Its advanced technology ensures that every batch meets strict quality standards, supporting consistent results and efficient operation. For companies looking to expand their product range or improve the quality of their existing candies, the starch mogul is an essential component of a modern, high-performance production line.

The starch mogul line stands out for its innovative features that drive both efficiency and product quality. At its core is a servo driven depositing system, which guarantees precise and consistent depositing of candy solutions—crucial for achieving uniform shape, size, and texture in every piece. This level of control is especially important when producing complex products like center-filled or multi-layer gummies.

Safety and product integrity are further enhanced by the inclusion of a strong magnetic filter, which actively removes metal contaminants from the production process. The integrated starch collecting and recycle system not only reduces raw material waste but also streamlines production, making the entire operation more sustainable and cost-effective. Automation throughout the mogul line helps save labor costs, allowing your team to focus on higher-value tasks while the system handles repetitive processes.

Additionally, the brushless design of the machinery minimizes maintenance needs and reduces the risk of contamination, supporting both product safety and long-term reliability. These advanced features make the starch mogul line a smart investment for any candy manufacturer seeking to boost productivity, ensure quality, and maintain a competitive edge.

Choosing a modern production line equipped with a starch mogul brings a host of operational advantages. High output is achieved through the line’s large capacity and efficient design, allowing you to meet even the most demanding production requirements. The fully automatic system ensures easy operation, with intuitive controls and recipe management that safeguard both stability and product safety.

The servo driven depositing system delivers precise, repeatable results, while the starch collecting and recycle system minimizes waste and maximizes resource utilization. Supporting the main production process, the ancillary system provides essential auxiliary functions that keep the whole line running smoothly. Meanwhile, the product finishing system ensures that every batch of candy is perfectly prepared for packaging, meeting your quality standards and customer expectations.

Whether you’re scaling up production or diversifying your product range, this production line is engineered to adapt to your needs—delivering consistent quality, operational efficiency, and the flexibility to handle a wide variety of recipes and candy types.

When it comes to producing top-quality gummy candies, gelatin base candies, and pectin based candies, our starch mogul line offers a solution that’s both advanced and adaptable. Designed with the needs of modern manufacturers in mind, our mogul line can be tailored to fit your specific production goals—whether you’re focused on classic gummies, innovative center-filled treats, or specialty confections.

Our commitment to customer satisfaction goes beyond the machine itself. From initial consultation to installation and ongoing maintenance, our team of experts is here to support you every step of the way. We make it easy to get in touch—whether by email, message, or phone—so you always have access to the guidance you need.

Sustainability is also a priority: our machines are engineered for energy efficiency and reduced environmental impact, helping you meet your production targets while supporting your company’s green initiatives. With a focus on quality, advanced technology, and responsive service, our mogul line solution is the smart choice for any business looking to excel in the competitive world of candy manufacturing.