Are you looking for the ideal gummy bear production line to enhance your candy manufacturing process? Look no further! As the #1 gummy bear production line wholesaler, we offer high-quality equipment directly from our trusted factory, eliminating the middleman to provide you with the best prices and service.

Direct from Factory: When you purchase from us, you’re buying directly from the manufacturer. This means no middleman, which translates to lower costs and more reliable service.

Industry-Leading Warranties: We stand behind our equipment with comprehensive industry warranties. You can trust in the durability and performance of our machines.

24/7 Support: Our dedicated customer support team is available around the clock to assist you with any questions or issues that may arise. We’re here to ensure your production line runs smoothly.

Quick Quotes: Need a quote fast? We provide quotes in 5 minutes or less, ensuring you can make informed decisions quickly and efficiently.

Competitive Pricing: As a factory-direct supplier, we offer the most competitive prices on gummy bear production lines. Our OEM/ODM services allow for customization to meet your specific needs, all at the lowest possible prices.

High Efficiency: Our production lines are designed for maximum efficiency, capable of producing large quantities of gummy bears with consistent quality.

Advanced Technology: Incorporating the latest technology, our machines offer precise control over the gummy production process, ensuring uniformity and high standards.

Customizable Options: Whether you need specific shapes, sizes, or flavors, our equipment can be customized to meet your unique requirements. We offer a variety of molds and configurations to suit your production needs.

Hygienic Design: Our gummy bear production lines use a starch-free process, which is more hygienic and cost-effective. The equipment is easy to clean and maintain, ensuring a safe production environment.

Durable Construction: Built to last, our machines are made with high-quality materials and components from international brands, ensuring long-term reliability and performance.

Factory Layout Planning: We help you design the optimal layout for your production facility, maximizing efficiency and workflow.

3D Design & Project Planning: Our experts provide detailed 3D designs and comprehensive project planning to ensure your production line is set up for success.

Technical Support: With over 40 years of experience, our team of professional engineers is available to offer technical support and troubleshooting whenever needed.

Custom Candy Formulas: We assist in developing custom candy formulas that align with your production goals, ensuring your gummy bears stand out in the market.

By choosing our gummy bear production lines, you are investing in reliable, efficient, and high-quality equipment that is tailored to meet your specific needs. With our commitment to customer satisfaction and industry-leading support, you can be confident in your decision to partner with us.

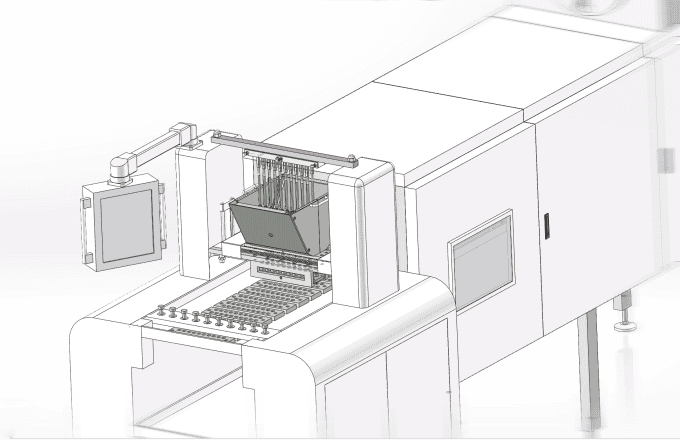

Elevate your candy production process with our state-of-the-art 40-Mini Automatic Candy Depositor. Engineered for precision, efficiency, and convenience, this machine is the perfect solution for small to medium-sized candy manufacturers looking to enhance their production capabilities.

Temperate Setting Hopper: Achieve precise temperature control with our innovative temperate setting hopper, ensuring consistent candy quality and optimal ingredient mixing.

Servo Depositing: Experience enhanced accuracy with servo-driven depositing technology. This system allows for precise control over candy deposition, resulting in uniform product size and weight.

PLC Adjustable Depositor Size Control: Easily adjust depositor sizes with our user-friendly PLC system. This programmable logic controller (PLC) offers flexibility in production, allowing you to create a variety of candy shapes and sizes with ease.

24-Cavity Per Shot: Maximize production efficiency with our 24-cavity per shot capability. This feature enables you to produce a high volume of candies in each cycle, boosting overall output.

Digital Oil Sprayer: Ensure smooth candy release and a glossy finish with our digital oil sprayer. This automated system evenly coats the candy molds, enhancing product quality and appearance.

Automatic Transfer to Multi-Layer Cooling System: Streamline your production process with automatic transfer to a multi-layer cooling system. This feature ensures rapid and uniform cooling, preserving the candy’s texture and taste.

Automatic De-Mold and Transfer Out: Simplify post-production with automatic de-molding and transfer out capabilities. This reduces manual labor and speeds up the production line, increasing overall efficiency.

Digital Variable Temperature Control: Maintain optimal production conditions with digital variable temperature control. This allows for precise temperature adjustments, ensuring consistent quality across all batches.

Free Spare Parts for Maintenance: Enjoy peace of mind with our complimentary spare parts package. We provide essential components to ensure minimal downtime and easy maintenance.

Quick Assembly & Quicker Use: Get up and running in no time with our quick assembly design. The 40-Mini Automatic Candy Depositor is engineered for easy setup and immediate use, minimizing disruptions to your production schedule.

Visual Window Safety Production Protect: Enhance safety with our visual window protection feature. This allows operators to monitor the production process in real-time while ensuring protection from potential hazards.

Compact Space-Saving Design for 13ft Length: Optimize your workspace with our compact, space-saving design. At just 13 feet in length, this machine is ideal for facilities with limited space, providing high production capacity without sacrificing floor space.

Investing in our 40-Mini Automatic Candy Depositor means choosing a machine that combines cutting-edge technology, efficiency, and ease of use. Perfect for candy manufacturers aiming to enhance production quality and capacity, this depositor offers the tools you need to succeed in a competitive market.

Contact us today to learn more about how the 40-Mini Automatic Candy Depositor can transform your candy production line. Experience the benefits of advanced automation, precision control, and unmatched efficiency.

Vitamins, Minerals, Fibre, CBD, Energy Supplements, OTC Medications,100% Fruit Pastes & Pieces, Low-sugar & Sugar-Free Products

Elevate your culinary capabilities with our state-of-the-art Moveable Cooking System, designed to bring flexibility, efficiency, and precision to your kitchen operations. Ideal for small batch cooking, this innovative system combines advanced features with a compact, portable design to meet the demands of professional kitchens, catering services, and food production facilities.

Small Batch Cooker on Cart/Wheel: Enhance mobility and convenience with our compact cooker mounted on a sturdy cart with wheels. Easily move the unit to different workstations or storage areas, optimizing space and workflow efficiency.

Independent Control System: Achieve precise cooking control with our fully independent control system. This feature allows for customized settings, ensuring each batch is cooked to perfection according to your specific requirements.

Temperature Setting: Enjoy accurate temperature control with our intuitive temperature setting feature. Adjust and maintain optimal cooking temperatures for a variety of recipes, ensuring consistent and high-quality results.

Scraping Stirring Mechanism: Prevent sticking and burning with our innovative scraping stirring mechanism. This system continuously scrapes the sides and bottom of the cooking vessel, ensuring even heat distribution and thorough mixing.

Integrated Homogenizer: Achieve smooth and uniform mixtures with our built-in homogenizer. This feature is perfect for creating emulsions, sauces, and other finely blended products, enhancing the texture and quality of your culinary creations.

Digital Display: Monitor and adjust cooking parameters with ease using our user-friendly digital display. This interface provides real-time feedback on temperature, stirring speed, and other critical settings, ensuring precise control over the cooking process.

Visual Window: Keep an eye on your cooking progress with our convenient visual window. This feature allows for continuous monitoring without the need to open the cooker, preserving heat and maintaining cooking efficiency.

Convenient Discharge: Simplify the transfer of cooked products with our convenient discharge system. Designed for ease of use, this feature ensures a smooth and efficient transfer of contents, minimizing waste and reducing cleanup time.

Quick Assembly & Quicker Use: Get up and running quickly with our easy-to-assemble design. The Moveable Cooking System is engineered for rapid setup, allowing you to start cooking immediately and minimizing downtime.

Investing in our Moveable Cooking System means embracing a versatile and efficient solution for your small batch cooking needs. Whether you’re a professional chef, caterer, or food producer, this system offers the mobility, precision, and convenience required to excel in a competitive culinary environment.

Contact us today to learn more about how the Moveable Cooking System can revolutionize your kitchen operations. Experience the benefits of advanced cooking technology, enhanced efficiency, and unparalleled versatility.

It is an automatic ingredient dissolving and mixing system for pre-cooking the syrup of candy and beverage solutions.

Mix raw materials such as sugar and glucose. Add all the raw materials into the cooker, the cooking is complete, and the syrup will be transferred to the storage tank through the pump. The storage tank adopts a multi-layer design, and the interlayer can be filled with hot and cold water to maintain the temperature of the liquid in the tank, and cool or store different types of pectin or gelatin as a buffer tank for continuous production.

Colors, Flavors, and Acid Powder (CFA) Integration: Our CFA system is engineered to enhance the flavor, color, and acidity of your confections by adding these elements directly to the syrup. This system also accommodates the addition of active ingredients, ensuring a seamless integration of various additives.

Core Components:

Advanced Accuracy: To maintain the highest accuracy, a flow meter control loop can be integrated with the pump, ensuring precise measurement and consistent quality.

Independent Systems: Each additive has its own dedicated system, supplied independently to the pouring device. This modular approach allows for flexibility and precision in the mixing process.

Mixing Options: Additives can be incorporated into the syrup using either a static or dynamic in-line mixer, with the choice depending on the nature of the additives. The mixing cone is then opened to blend the ingredients thoroughly.

Precision Oil Application: Our oil sprayer features individual nozzles with a cone-shaped spray pattern, efficiently coating the cavities of the mold. This design saves oil and maintains sanitary conditions, ensuring clean and consistent results.

Enhanced Precision and Control: The servo depositor utilizes servo control for greater precision and quieter operation. The touch screen interface allows for easy adjustment of product weight, ensuring uniformity and quality in every batch.

Optimized Production Flow: The servo-drive conveyor adjusts the synchronization with the depositing process and the cooling time, enhancing overall efficiency and ensuring a smooth production flow.

Efficiency in Mold Management: Our quick-release mold system is uniquely designed to minimize installation and disassembly time, reducing labor costs and improving production efficiency. This system allows for rapid changes and adjustments, facilitating a more flexible production process.

Advanced Cooling Technology: Our new freezer system quickly cools down the candy, accelerating its formation and significantly improving production efficiency. The cooling tunnel uses environmentally friendly refrigerants, meeting the high environmental standards required in Europe, America, and other regions.

Versatile Finishing Options: Depending on your needs, our de-molding system can be equipped with sugar powder coating machines and polishing machines to create candies with various colors and finishes. This flexibility greatly enriches the appearance and variety of your products.

Cost-Effective Investment: Our small drying equipment offers a cost-effective solution for new businesses, reducing initial investment costs. As your confectionery business grows, you can easily upgrade to large-scale production equipment, ensuring scalability and continued success.

Why Choose Our Candy Production Systems?

Experience and Expertise: With over 40 years of machine manufacturing experience, our factory is a trusted name in the industry. Our team of 12 drawing designers and 20 professional engineers is dedicated to providing technical support and innovative solutions tailored to your needs.

Reliability and Quality: Our modern factory, staffed by over 200 workers, operates under strict quality control systems and advanced German standards. Our CNC machining center ensures precise technology processes, handling every detail of each machine with care.

High-Quality Machines: All our machines are manufactured in a GMP standard factory, using SUS304 and sandblasting surface coating treatments to ensure durability and compliance with international standards.

Comprehensive Support: We offer a range of services, including factory layout planning, 3D design and project planning, customized shape design, and product formulation support. Our commitment to excellence ensures that you receive the best solutions and support for your confectionery production needs.

Invest in our advanced candy production systems to enhance your production capabilities, improve efficiency, and ensure the highest quality in your confectionery products. Contact us today to learn more about how we can support your business growth and success.

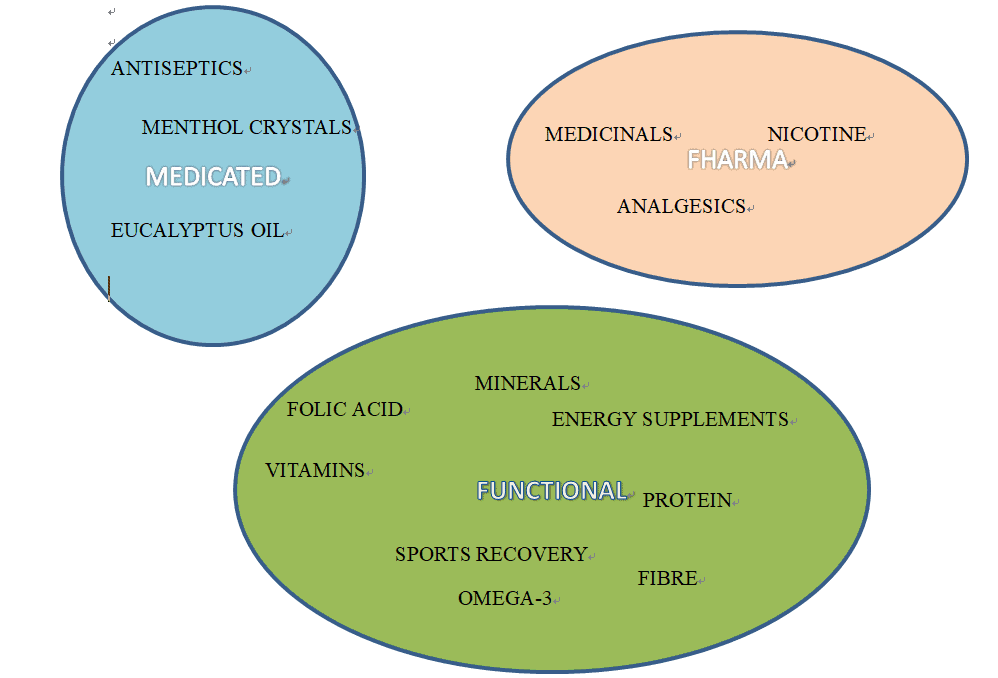

As consumers realize that treating diseases and adjusting their diet is not necessarily an unpleasant experience, they are increasingly using functional confectionery products to achieve the effects of over-the-counter drugs or dietary supplements.

Functional and medicated candies are not uncommon, but the accuracy and hygiene of modern cooking and deposition techniques have expanded their potential applications.

Our team focuses on creating high-quality customized functional jelly candy production lines. We produce a wide variety of various confectionery machines, which are consistent throughout our production line-high-quality machines help to make delicious and healthy gummies!

JY MACHINE is a premier manufacturer of production equipment for the food industry, based in China. We specialize in providing comprehensive production lines and individual machines for candies and biscuits to clients worldwide. Our customer base spans from small, independent manufacturers to large multinational corporations.

In addition to serving the food industry, we also offer innovative solutions for healthcare and pharmaceutical companies. Our systems are designed to meet stringent industry standards, and we provide extensive documentation, Factory Acceptance Testing (FAT), and on-site support to ensure compliance and customer satisfaction.

Our confectionery equipment innovation center in China is a testament to our commitment to continuous improvement and innovation. We’ve invested significantly in our facilities and staff, fostering an environment where we collaborate with customers to develop new products and process innovations. Clients utilizing our innovation center have access to a full suite of cooking and pouring systems, supported by our experienced technicians throughout and beyond the commissioning phase of each project.

Our equipment is designed to incorporate functional elements into gummy candies, enhancing nutritional intake. These elements can range from essential nutrients like vitamins, minerals, fiber, and protein to beneficial supplements such as folic acid and omega-3. Our systems are also ideal for producing sports nutrition products, providing portable and convenient energy supplements.

Our advanced deposition systems enable the incorporation of various active ingredients at different stages of the production process:

The cooking and deposition processes are crucial for the successful production of functional and medicated candies. While cooking is performed at high temperatures, the addition of active ingredients is typically delayed until just before deposition to prevent loss or degradation. Deposition occurs at lower temperatures and is followed by rapid cooling to stabilize the composition.

Our high-precision metering and dosing equipment ensure the correct proportion of active ingredients is added to the cooked syrup. Coupled with the precise piece weight control provided by the deposition process, this results in each piece containing the accurate amount of active ingredient. This level of control is particularly important for cost management, especially when over-dosing active ingredients is necessary to ensure an acceptable shelf life.

Expertise and Experience: With over 40 years in machine manufacturing, JY MACHINE brings a wealth of knowledge and expertise to the table. Our team includes 12 drawing designers and 20 professional engineers, ready to provide technical support anytime and anywhere.

Reliability and Quality: Our modern factory, staffed by over 200 workers, operates under strict quality control systems and advanced German standards. Our CNC machining center ensures precise technology processes, handling every detail with care.

Comprehensive Support: We offer a range of services, including factory layout planning, 3D design and project planning, customized shape design, and product formulation support. Our commitment to excellence ensures that you receive the best solutions and support for your confectionery production needs.

Invest in JY MACHINE’s advanced production systems to enhance your production capabilities, improve efficiency, and ensure the highest quality in your confectionery products. Contact us today to learn more about how we can support your business growth and success.

A: Yes, we offer a comprehensive plan, including everything from formula development to product support.

A: Yes, this machine can also produce taffy candy and lollipops.

A: We customize the equipment according to your voltage specifications. Based on different voltages, we will calculate the ampere requirements for you.

A: Yes, our machines are CE certified and use UL & EU listed brands, strictly adhering to GMP standards.

A: Considering most customers’ space limitations, this machine only needs to be connected to power. This design saves on costs and eliminates the complexity of compressed air flow. The machine uses a servo system for simpler and smarter control, with no need for additional systems.

A: You can adjust the temperature and candy weight using the control box and touch screen settings.

A: No, the machine is fully automatic from the depositor to the cooling stage. You only need to collect the candy at the machine exit.

A: The machine’s electrical components are connected via quick couplers, and settings are adjusted through a touch screen interface similar to a smartphone. If needed, our local technology support team can assist with installation.

A: Contact us now for detailed pricing information!

We provide a comprehensive range of equipment and support for nutrition gummy bear candy making machines. If you’re interested in these machines, you can browse related products and initiate consultations on our website.

For more details, visit our website and explore our extensive product range, or contact us directly for personalized consultations.