Before you can understand how CBD “gummies” are produced, you should first know what they are. They are chewy CBD candies, which have long been a popular confection and supplement base. Fortunately, manufacturers of candy machines have the manufacturing process down to a science. They have both low and high-volume production lines, and they are capable of producing gummies in a variety of flavors.

Making a CBD gummy

The manufacturing process of a CBD gummy involves combining raw ingredients in a mixture and molding them into desired shapes. After the desired shape has been created, the CBD gummies are transported by conveyor belts to a starch buck, where they are dropped onto metal screens. The finished CBD gummies are then decorated to improve their appearance and shelf life. Finally, they go through a final inspection and are ready for sale.

In order to create a CBD gummy, the hemp or marijuana-derived CBD oil is first refined. Then it is ready for incorporation into gummies. The process of making a CBD gummy is very similar to that of making extra-thick Jell-O. A mixture of sugar, thickener, and flavorings are added until the CBD is fully absorbed. Finally, the finished product is ready for packaging.

Ingredients

A CBD gummy can contain a variety of ingredients, ranging from pure cane sugar to honey and other naturally sweeteners. There are no preservatives used in CBD gummies. It is important to store them in an airtight container. Many recipes also use beet juice, which is naturally sweet, and can be substituted for pure cane sugar. Other common ingredients include beets, coconut, and pomegranate juice.

First, you should heat the CBD oil. You can use this straight away or store it for later use. CBD oil is shelf stable for several months. The potency and quality of the final product will not decrease after a few months of storage. Lastly, you should place the moulds close to a heating element. While filling them, gently warm the CBD oil. Be careful not to overheat the CBD oil, because the foam will affect the texture of the finished product. Make sure to use an unflavored gelatin pack.

Flavors

A factory can make different flavors of CBD gummies, but quality is always a top priority. Look for companies that use organic hemp and obtain their extracts through CO2 extraction. A quality brand will regularly test their products in independent laboratories to ensure their product quality. The results of these tests are posted on the company’s website so you can see for yourself. Avoid buying cheap, low-quality CBD gummies because they are often made from hemp that is grown with hazardous chemicals. The extraction process for these products can involve harmful solvents as well, so beware of cheap CBD gummies.

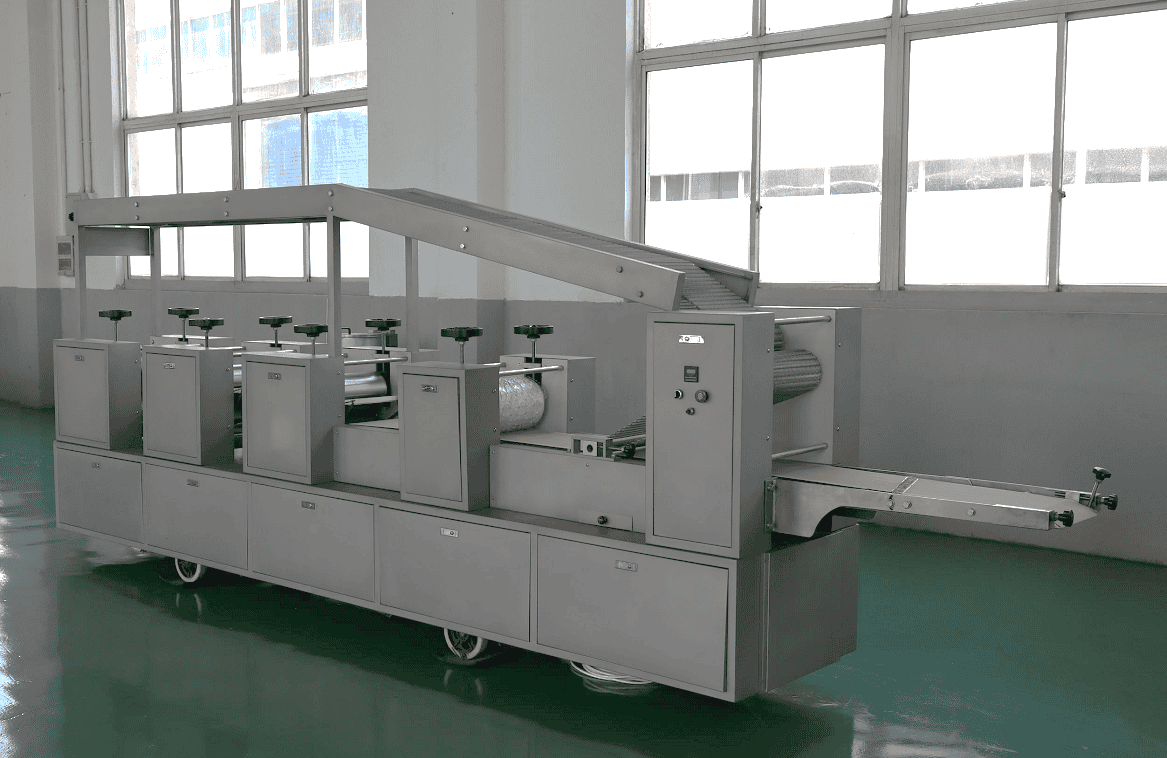

A CBD gummy made in a factory is produced with a special machine that cools the hot gummy candy and controls air pressure. The machines utilize unique equipment to detect any irregularities in the manufacturing process and prevent product malfunctions. CBD comes naturally from hemp and marijuana plants, so most CBD gummy brands use extracts from both plants. This ensures that the final product is as high-quality as possible.

Cost of manufacturing a CBD gummy

The first step in producing a CBD gummy is to select the right ingredients. The CBD gummies that you choose should contain ingredients that are suitable for your business. These can range from herbs to fruit extracts. Then, you will need to determine how much of these ingredients you want to use. This will determine how much production capacity you will require and how much automation you need. Once you have selected the right ingredients, you can move on to the next step, which is to design the perfect machine.

You’ll also need to consider the packaging for your CBD gummies. While they should be stored in a refrigerator, they should be kept in a sealable bottle. Consider incorporating recyclable packaging into your CBD gummies. You may also want to look into compostable bags or pouches. Aside from being child-resistant, these containers should also be food-grade. Lamination also offers oxygen, moisture, and odor protection.