Guide technique sur les essais de dureté dans la production de bonbons : Principes et applications

Les essais de dureté jouent également un rôle essentiel dans l'ingénierie des procédés alimentaires, en particulier dans la production de confiseries. Dans l'industrie de la confiserie, la dureté n'est pas seulement une mesure de laboratoire - c'est un paramètre critique de contrôle de la qualité qui est en corrélation avec la texture, la durée de conservation, la résistance à la morsure et la perception du consommateur. En appliquant des tests de dureté systématiques, les ingénieurs peuvent garantir la cohérence, détecter les dérives du processus et contrôler les changements de formulation ou de traitement thermique.

Dans ce guide, nous allons :

-

Expliquer la signification scientifique de la dureté dans le contexte des bonbons (souvent viscoélastique, cassant ou plastique selon la recette),

-

Examiner les principales méthodes (indentation, perforation, compression) adaptées à la confiserie,

-

Montrer comment choisir la bonne méthode d'essai pour les différents types de bonbons (bonbons durs, à mâcher, confiseries enrobées),

-

Fournir les meilleures pratiques en matière de préparation des échantillons, d'exécution des tests et d'interprétation des résultats afin d'obtenir des données significatives et reproductibles.

Plongeons dans le vif du sujet.

Que signifie le terme “dureté” dans le contexte des bonbons ?

En science des matériaux, la dureté est une mesure de la résistance à la déformation plastique (permanente) sous une charge localisée. Mais les bonbons et les confiseries diffèrent des métaux et des céramiques : ils se comportent souvent comme des matériaux viscoélastiques ou cassants en fonction de la cristallinité du sucre, de la teneur en humidité, de la transition vitreuse ou de la composition (par exemple, inclusion de graisses, de gommes).

La dureté d'un bonbon s'apparente donc davantage à sa résistance à l'indentation, à la fracture ou à la pénétration sous une charge mécanique définie.

Lorsque vous enfoncez une sonde dans un bonbon, vous pouvez voir :

-

Une reprise élastique (si le matériau est élastique),

-

Une indentation plastique ou permanente (si la structure cède),

-

Fissuration ou fracture (en cas de fragilité),

-

Fluage ou déformation en fonction du temps (si viscoélastique).

Dans la pratique, nous concevons des essais pour isoler la “résistance initiale”, c'est-à-dire le comportement de la charge en fonction de la pénétration avant qu'un fluage ou une fracture significatifs ne dominent.

En bref : la dureté des confiseries est un paramètre “fonctionnel” - elle reflète la microstructure interne (réseau cristallin, matrices de liaison, teneur en eau) et est liée à la force de morsure, au croquant, à la masticabilité ou au comportement en cas de rupture.

Méthodes courantes d'essai de dureté en confiserie

Les bonbons étant mous, cassants ou viscoélastiques, les tests d'indentation métallurgiques classiques (Rockwell, Brinell, Vickers, Knoop) doivent être adaptés ou sont souvent remplacés par des méthodes plus courantes dans le domaine des sciences alimentaires : essais de perforation, de compression, de flexion en trois points et d'indentation à l'aide de petites sondes. Mais le principe sous-jacent - mesurer la résistance à une charge connue en fonction du déplacement - reste le même.

Voici les méthodes typiques utilisées (ou adaptées) dans les milieux de la confiserie :

| Méthode | Principe | Meilleur pour le type de bonbon | Avantages / inconvénients |

|---|---|---|---|

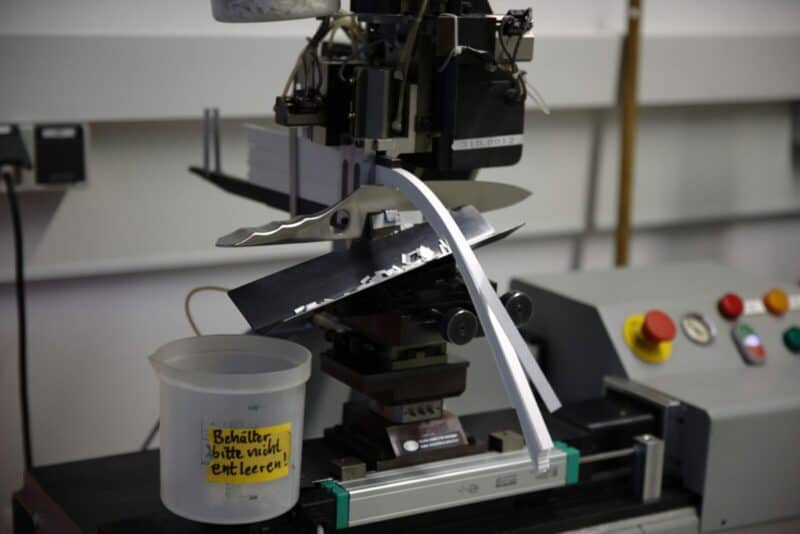

| Test de perforation / pénétration | Enfoncer une sonde pointue (par exemple, une aiguille, une lame) dans l'échantillon, mesurer la force et le déplacement. | Bonbons mous (gommes, gels, fondants) | Simple, direct ; mais les effets de bord, la géométrie de la sonde sont importants |

| Analyseur de compression/texture (platine 2 points) | Sandwicher le bonbon entre des plaques plates et le comprimer à un taux contrôlé | Bonbons durs, barres, centres en chocolat | Bon pour la force par rapport à la déformation ; mais peut entraîner une déformation globale |

| Essai de flexion à trois points | Soutenir l'échantillon en deux points, appliquer la charge au centre. | Bonbons rigides, morceaux de sucre en verre | Mesure la force de rupture / la rigidité en flexion |

| Indentation instrumentée / micro-indentation | Utiliser un petit pénétrateur (pyramidal, sphérique) pour marquer la surface. | Enrobages de bonbons, couches minces, surfaces de bonbons durs | Sensible, permet la cartographie ; mais un étalonnage soigneux est nécessaire |

| Mécanique dynamique / dureté (impact / rebond) | Méthodes de la balle tombante ou du rebond pendulaire | Bonbons durs cassants, enrobages de coquilles cassantes | Non-destructif pour l'encombrement ; correspond à la sensation de “claquement” du consommateur. |

Adaptation des méthodes métalliques

-

Des charges plus faibles et des pénétrateurs plus petits: Les bonbons étant beaucoup plus mous, il faut utiliser de petites forces (par exemple de quelques grammes à quelques newtons) et des sondes fines.

-

Temps de séjour courts (ou mode continu) pour minimiser les effets de fluage.

-

Compensation du fluage ou de la relaxation viscoélastique, éventuellement en mesurant le temps ou les caractéristiques de la courbe de déchargement.

-

Préparation d'une surface plane et homogèneLes produits de la catégorie "bonbons" : couper, polir ou aplanir les surfaces des bonbons pour réduire les irrégularités géométriques ou superficielles.

-

Étalonnage avec des matériaux de référence: Utiliser des blocs d'étalonnage ou des étalons (par exemple des matériaux polymères) dont la dureté est connue pour valider le comportement de l'instrument dans la zone de faible charge.

Choix d'une méthode d'essai pour différents types de bonbons

Pour choisir le meilleur test de dureté/texture, il faut tenir compte des éléments suivants :

-

Type et structure des bonbons

-

Dur bonbons / sucre verre / sucettes: cassant, faible humidité, grande rigidité → utiliser les essais de compression, de flexion ou de rebondissement.

-

Chewy / gommeux / gélatineuxLes produits de cette catégorie sont les suivants : viscoélastique, humidité élevée → perforation ou petites empreintes, temps de séjour plus courts.

-

Confiseries enrobées / coquilles d'enrobageLes méthodes d'indentation sont les suivantes : indentation locale sur des couches minces ou cartographie de la surface → micro-indentation ou indentation instrumentée.

-

-

Géométrie et épaisseur de l'échantillon

La pénétration de l'essai (profondeur d'indentation ou déflexion) doit être nettement inférieure à l'épaisseur totale pour éviter les effets de support (règle empirique : profondeur d'indentation < 10% de l'épaisseur). -

Données souhaitées / débit

Pour un contrôle de qualité à haut débit, simple compression ou perforation des tests avec des analyseurs de texture automatiques sont préférables. Pour la R&D ou l'analyse des défaillances, la cartographie par indentation instrumentée permet d'obtenir des détails spatiaux plus riches. -

Destruction et non-destruction

Certains tests (compression, perforation) peuvent fracturer ou abîmer les bonbons ; des tests d'indentation douce ou de rebond peuvent laisser la masse intacte. -

Sensibilité à l'humidité, à la température et à l'histoire

Les bonbons étant sensibles aux changements environnementaux, vous devez contrôler la température et l'humidité du test, et effectuer le test peu de temps après la préparation de l'échantillon afin de réduire la dérive.

Bonnes pratiques en matière de préparation et d'exécution des échantillons

Même de petites erreurs dans la préparation ou l'exécution de l'échantillon peuvent entraîner des écarts importants dans les données relatives à la dureté/texture. Les lignes directrices ci-dessous permettent d'obtenir des résultats fiables et reproductibles :

Préparation de l'échantillon

-

Coupe / Sectionnement: Utiliser des méthodes qui minimisent la production de chaleur ou les dommages structurels (lames tranchantes, scies refroidies).

-

Planéité de la surface: Pour l'indentation ou les microtests, aplanir ou polir la surface. Utiliser le micro-rabotage ou le rodage avec des abrasifs fins si nécessaire (pour le verre à sucre, etc.).

-

Montage: Pour les pièces petites ou minces, monter sur un support rigide ou dans un dispositif qui maintient l'échantillon sans déformation.

-

Équilibre des températures: Laisser l'échantillon se stabiliser à la température d'essai (par exemple, essai dans une chambre à température contrôlée) pour éviter les effets de ramollissement thermique.

Exécution des tests

-

Espacement / Distance des bords: Les empreintes ou les pénétrations doivent être éloignées des bords ou des essais précédents. Une règle : au moins 3× la plus grande dimension (indentation, pointe de la sonde) par rapport au bord ou à l'essai précédent.

-

Chargement du profil: Utiliser une charge cohérente (taux, temps de séjour). Pour les matériaux viscoélastiques, inclure une précharge (force mineure) puis une charge principale afin d'éliminer les effets de surface.

-

Étalonnage des instruments / contrôles de base: Utiliser des matériaux de référence standard (par exemple des blocs de polymères de module/dureté connus) pour vérifier la réponse de l'instrument dans la gamme des faibles forces.

-

Courbe de décharge / mesure résiduelle: Dans les essais instrumentés, saisir les courbes complètes de charge et de décharge pour tenir compte de la récupération élastique et calculer une “pseudo-dureté” ou un module d'indentation.

-

Mesures répétées et échantillonnage statistique: Pour les bonbons non uniformes (bulles d'air, inclusions), prenez plusieurs mesures et indiquez la moyenne ± l'écart type.

Résolution des problèmes courants dans les tests de dureté des bonbons

| Problème / Observation | Cause probable | Remède |

|---|---|---|

| Grande dispersion entre les points de données de pénétration ou d'indentation | Hétérogénéité de l'échantillon, bulles, irrégularité de la surface | Augmenter le nombre de mesures, éviter les zones défectueuses, améliorer la préparation de la surface |

| L'indentation présente une “dérive de fluage” (augmentation lente pendant le temps de séjour). | Flux viscoélastique ou chaleur pendant le chargement | Réduction de la durée d'immobilisation, utilisation de méthodes de chargement et de déchargement, compensation de la pré-fluctuation |

| Fracture / fissuration lors de l'indentation | Charge trop élevée pour un bonbon fragile, concentration de contraintes | Réduire la charge, utiliser des pointes sphériques ou des sondes plus lisses, utiliser le test de rebond à la place. |

| Courbes force-déplacement dérive ou décalage de la ligne de base | Dérive de l'instrument, dérive thermique, conformité de l'appui | Remise à zéro de la ligne de base, réchauffement de l'instrument, utilisation d'un support plus rigide, vérification de l'alignement de la sonde. |

| Différences de dureté dans le temps | Migration de l'humidité, changement de température, vieillissement | Tester les échantillons peu de temps après leur préparation, contrôler étroitement l'humidité et la température. |

Interprétation des données de dureté pour la performance des bonbons

Une fois que vous disposez de mesures fiables, comment les relier à vos objectifs ? la qualité des produits et le contrôle des processus? Voici quelques lignes directrices :

-

Corrélation avec les données sensorielles/de consommation: La dureté (force à un certain déplacement) est souvent en corrélation avec la perception de la “dureté”, du “craquement” ou de la “force de morsure”. Recueillir des données sur les panels afin d'établir une correspondance entre les chiffres mécaniques et la perception de l'utilisateur.

-

Suivi de la cohérence et de la dérive des processus: Utilisez la dureté comme mesure de contrôle pour assurer la cohérence d'un lot à l'autre. Les écarts peuvent signaler des changements de température de cuisson, de teneur en humidité, de cristallisation ou de variation des ingrédients.

-

Variation spatiale de la carte / uniformité de la coquille: Dans les bonbons enrobés, utilisez des indentations multiples dans différentes régions (par exemple, le bord par rapport au centre) pour détecter les gradients d'épaisseur ou de dureté.

-

Défaillance ou rupture du modèle: Pour les bonbons fragiles, combiner la dureté (résistance à l'amorçage de fissures) avec la ténacité à la rupture (à partir d'essais de flexion) pour prédire la propagation des fissures ou le comportement à la rupture sous l'effet d'un impact.

-

Effets de l'humidité et du vieillissement: Surveiller la dureté au cours de la durée de conservation pour voir les effets du ramollissement, de la recristallisation et de la pénétration de l'humidité. Les courbes de dureté au fil du temps peuvent mettre en évidence des problèmes de stabilité.

- ASTM International - Normes d'essai de dureté https://www.astm.org/

- ISO - Organisation internationale de normalisation https://www.iso.org/

- ASM International - Essais et caractérisation des matériaux https://www.asminternational.org/

- NIST - Institut national des normes et de la technologie https://www.nist.gov/

- SAE International - Matériaux et normes d'essai https://www.sae.org/

- ASME - Société américaine des ingénieurs en mécanique https://www.asme.org/

- La société des minéraux, métaux et matériaux (TMS) https://www.tms.org/

- Société de mécanique expérimentale (SEM) https://www.sem.org/

- Société de recherche sur les matériaux (MRS) https://www.mrs.org/

- ANSI - American National Standards Institute (Institut national américain de normalisation) https://www.ansi.org/