The Jelly/Gummy/Gelatin/Pectin/Carrageenan Candy Depositing Line is the ultimate solution for producing high-quality confections with exceptional consistency. Designed to meet the demands of modern candy production, this line not only delivers superior product quality but also enhances operational efficiency.

| Modèle | M80 | M150 | M300 | M450 | M600 |

| Capacité de production | 80 kg/hour | 150kg/hour | 300kg/hour | 450kg/hour | 600kg/hour |

| Eletric Power | 2-8 g/ou plus personnalisé | 2-8 g/ou plus personnalisé | 2-8 g/ou plus personnalisé | 2-8 g/ou plus personnalisé | 2-8 g/ou plus personnalisé |

| Total length | 7m | 17m | 17m | 18m | 18m |

| Mould quantity | 160pcs | 240pcs | 480pcs | 720pcs | 960pcs |

This line primarily consists of a Jacket Cooker, Storage Tank, Weighing and Mixing System, Depositor, and Cooling Machine. It incorporates an advanced servo control system for precise and efficient operation.

The Jacketed Mixing Tank and Jacketed Storage Tank are engineered with advanced features to ensure optimal performance. Both tanks utilize a hot water circulation system in the jacket and piping for efficient and uniform heating, ensuring precise temperature control during the cooking process.

The tanks are also equipped with a powerful vacuum pump, which helps to remove air and moisture from the mixture, enhancing product quality and texture. Crafted from durable, food-grade stainless steel 304, these tanks are built to withstand high temperatures and offer exceptional corrosion resistance, making them ideal for continuous operation in a high-demand production environment.

The cooking system is versatile and can be used to cook candy syrup, dissolve gelatin, and store syrup in a controlled manner, ensuring smooth and uninterrupted production flow. This seamless integration of cooking and syrup storage guarantees consistent, high-quality results in every batch. Designed for manufacturers looking to enhance their candy production capabilities, this system ensures efficiency, product consistency, and operational reliability, helping you meet the growing demands of the candy market.

The Dynamic and Static Inline Mixer is a high-efficiency system designed to seamlessly integrate color, flavor, and acid dosing into your production line. This advanced mixer offers both dynamic and static mixing capabilities, ensuring thorough and consistent blending of ingredients in real time.

With automatic dosing for color, flavor, and acid, this system enhances production speed and accuracy while reducing the need for manual intervention. It’s specifically engineered for convenience, making it easy to set up, operate, and maintain. The ability to automatically control the proportions of additives ensures consistent product quality across every batch, while the fast mixing process minimizes downtime and maximizes production efficiency.

Whether you’re producing gummy, candy, or other confectionery products, this mixer streamlines the entire process, improving both the quality and speed of your operations. Its user-friendly design and automation features provide candy manufacturers with a reliable, time-saving solution to meet the demands of today’s fast-paced market.

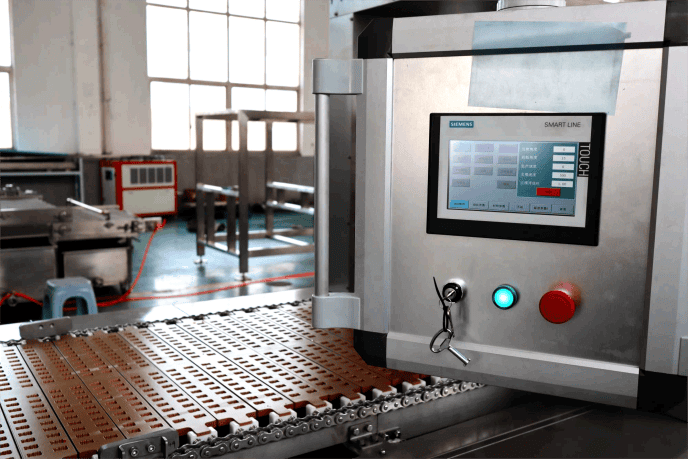

Designed to reduce manual labor, our system is equipped with an automatic oil spraying system, which facilitates easier demoulding of candies. This advanced feature ensures a smoother production process, saving time and enhancing operational efficiency by minimizing the need for manual intervention during the demoulding stage.

Our depositing machine is highly versatile and can produce a wide variety of candies, including single-color, double-color, and sandwich candies. This flexibility allows manufacturers to create a diverse range of products with ease, meeting market demands and offering creative possibilities to expand product lines.

With its seamless operation, time-saving features, and ability to produce a variety of candy types, our depositing machine is the ideal solution for manufacturers looking to streamline production while maintaining product quality and consistency.

Our cooling tunnel is constructed with a robust SUS304 stainless steel frame, known for its exceptional durability and resistance to corrosion. The frame is thickened for added stability during operation, ensuring smooth performance with minimal vibration and noise, even during extended use. This design not only enhances the reliability of the equipment but also contributes to a longer service life, making it a cost-effective choice for long-term production needs.

We’ve equipped our cooling tunnel with high-quality refrigeration systems, optimized for superior cooling efficiency. These advanced cooling systems ensure fast and consistent temperature control, improving the overall production process by reducing cooling times and maintaining the integrity of the candies.

Additionally, our equipment features smooth, well-finished surfaces, including the door handles, which are not only aesthetically pleasing but also easy to maintain and clean. The sleek, sturdy design ensures that the cooling tunnel is both visually appealing and built to withstand the demands of continuous operation in a high-performance environment.

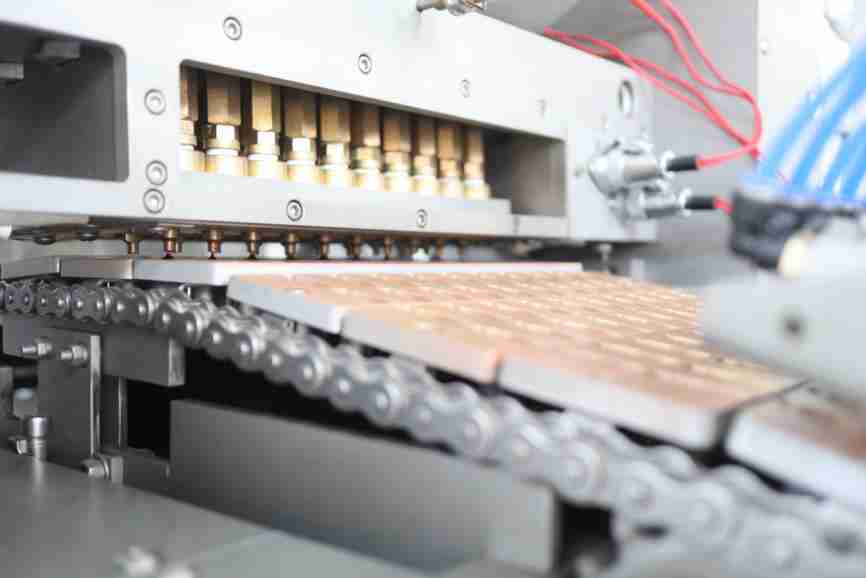

The movable controller adds an extra layer of flexibility and convenience to your operations, allowing operators to easily adjust settings and manage the system from different positions within the production area. This intuitive design makes it simple to monitor and control the entire process, enhancing workflow and reducing the time spent on manual adjustments.

In addition, the mold and chain are securely and stably fixed, ensuring a reliable and consistent production process. This stable setup minimizes the risk of malfunctions and ensures that each batch is produced with the utmost precision, maintaining high-quality standards throughout the production run.

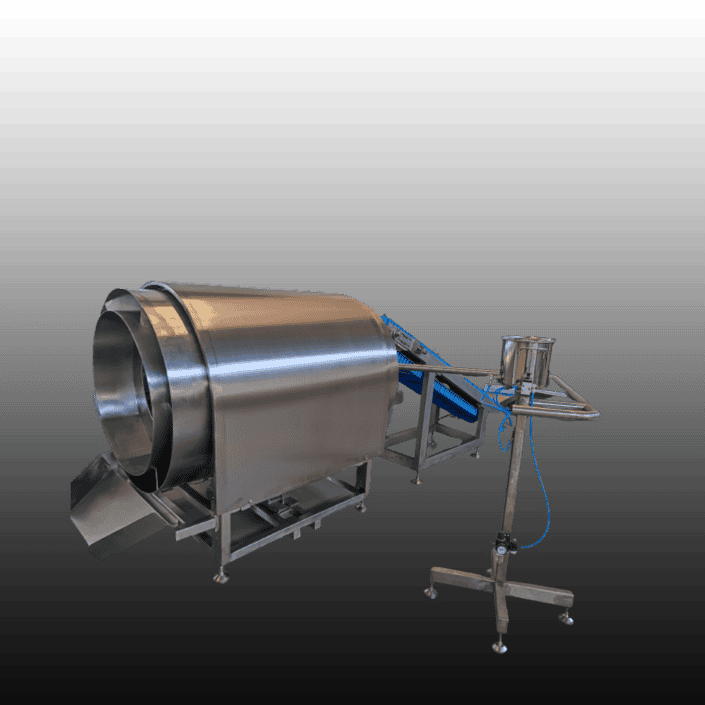

The Sugar/Oil Wrapping Machine is designed to provide uniform coverage of granulated sugar on each soft candy after undergoing multi-level rotating processing. This advanced system ensures that every piece is evenly coated, enhancing both the appearance and texture of the candy.

Constructed from high-quality stainless steel, the machine offers superior load-bearing capacity, ensuring durability and reliability even during extended use. The design also allows for easy adjustment of both capacity and height, making it adaptable to various production needs and different candy sizes, ensuring flexibility in meeting diverse manufacturing requirements.

Whether you’re producing small batches or large-scale runs, this machine is built to deliver consistent, high-quality results, streamlining the wrapping process and improving overall production efficiency.