Qui sommes-nous ?

À propos de Junyu

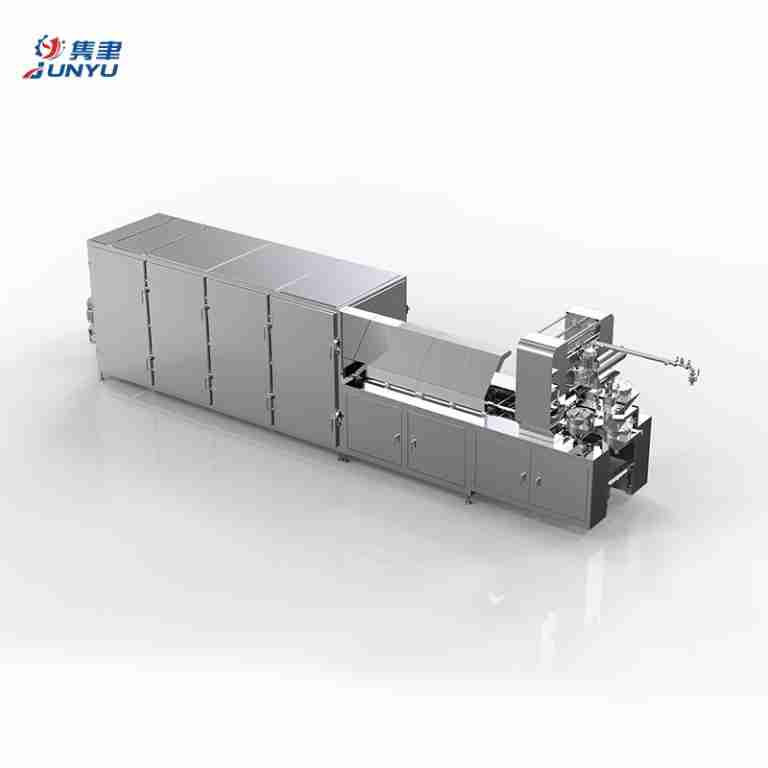

Junyu est un fabricant professionnel d'équipements alimentaires, tels quebiscuit making machines, Ligne de production de gâteaux, Candy Gummy, Ligne de production de gomme, Biscuit Production Line, snack food equipment, and so on. We have been in this line for more than 30 years. Our products are sold well worldwide and enjoy a good reputation among our customers.

Notre société a obtenu la certification du système de gestion de la qualité ISO9001:2008, et nous sommes également l'une des entreprises centrales de l'Association chinoise de l'industrie des équipements de préparation des aliments (CFPEA).

Nous souhaitons nous lier d'amitié avec vous grâce à nos produits de haute qualité et à notre service sincère.

Catégories de produits

02.

02. Ligne de production de bonbons

03.

03. Ligne de production de chocolat

04.

04. Machine à emballer les aliments

05.

05. Ligne de production de boba à éclater

06.

06. Ligne de production de gâteaux

Junyu

Nos services

Fabrication d'équipements alimentaires de haute qualité

Junyu specializes in the design and manufacturing of top-tier food equipment, including candy gummy systems, biscuit production lines, cake machinery, and snack food equipment. With over 30 years of industry experience, we ensure that every product we deliver meets the highest standards of quality and efficiency.

Distribution et réputation mondiales

Nos équipements alimentaires sont reconnus et vendus dans le monde entier, ce qui nous vaut une solide réputation de fiabilité et d'innovation. Où que vous soyez, Junyu veille à ce que ses produits répondent aux besoins des clients dans les différentes régions, en leur offrant une qualité et des performances constantes.

Gestion de la qualité certifiée ISO9001:2008

Junyu is committed to maintaining the highest standards of manufacturing excellence. From candy gummy equipment to our advanced biscuit production line systems, all products are certified under the ISO9001:2008 quality management system, guaranteeing precision craftsmanship and long-lasting performance.

Soutien complet à la clientèle

Nous nous engageons à fournir un service à la clientèle exceptionnel. De la consultation avant-vente à l'assistance après-vente, l'équipe de Junyu est toujours prête à vous aider à chaque étape de votre parcours d'achat. Que vous ayez besoin d'une assistance technique ou de conseils sur l'utilisation du produit, nous sommes là pour vous aider.

Leadership et collaboration au sein de l'industrie

En tant qu'entreprise centrale de l'Association chinoise de l'industrie des équipements de préparation des aliments (CFPEA), Junyu joue un rôle actif dans l'élaboration de l'industrie des équipements alimentaires. Nous collaborons avec d'autres leaders dans ce domaine pour nous assurer que nos produits sont non seulement innovants, mais aussi conformes aux dernières normes et tendances de l'industrie.

Des solutions sur mesure pour votre entreprise

We understand that every business has unique needs. Junyu offers customized food equipment solutions tailored to your specific production requirements. Whether you're looking for a candy gummy system, biscuit production line, cake machine, or snack equipment, our expert team will work with you to create the perfect solution for your operation.

Junyu

Candy Gummy Machine and Biscuit Production Line Machines

Fonctionnement simple Prix raisonnable Réglage de la température Dépose servo Réglable par PLC...

En intégrant des technologies avancées et des processus rationalisés, cette ligne aide...

Junyu

Nos clients