Jelly candy making machines are sophisticated pieces of equipment that, when operating smoothly, can produce delightful confections with ease. However, like any machinery, they can occasionally encounter issues that require troubleshooting.

This comprehensive guide offers a detailed look at common troubleshooting tips for maquinas para hacer dulces de gelatina, ensuring that your production line runs with minimal interruptions.

1. Understanding the Machine Manual

The first step in troubleshooting any issue is to have a thorough understanding of the machine’s operation. The manual is an invaluable resource that provides insights into the machine’s workings, common issues, and recommended solutions.

2. Regular Maintenance

Preventative maintenance is crucial for reducing the frequency of issues. Regular cleaning, lubrication, and inspection of the machine can help identify potential problems before they cause significant disruptions.

3. Power Supply Issues

Machines may not operate correctly if there are issues with the power supply. Check that the machine is properly plugged in, the circuit breaker hasn’t tripped, and there are no blown fuses or faulty wiring.

4. Hopper and Feeder Problems

If the hopper or feeder is not delivering ingredients correctly, it can lead to inconsistencies in the candy. Check for clogs, ensure the feeder is clean, and verify that all moving parts are functioning smoothly.

5. Mixing and Blending Issues

Uniform mixing is essential for jelly candy production. If the mixer is not blending ingredients properly, check for worn gears, incorrect speeds, or obstructions in the mixing chamber.

6. Temperature Control Failures

Proper temperature control is vital for the gelling process. If the machine is not heating or cooling as expected, inspect the thermostat, heating elements, or cooling systems for malfunctions.

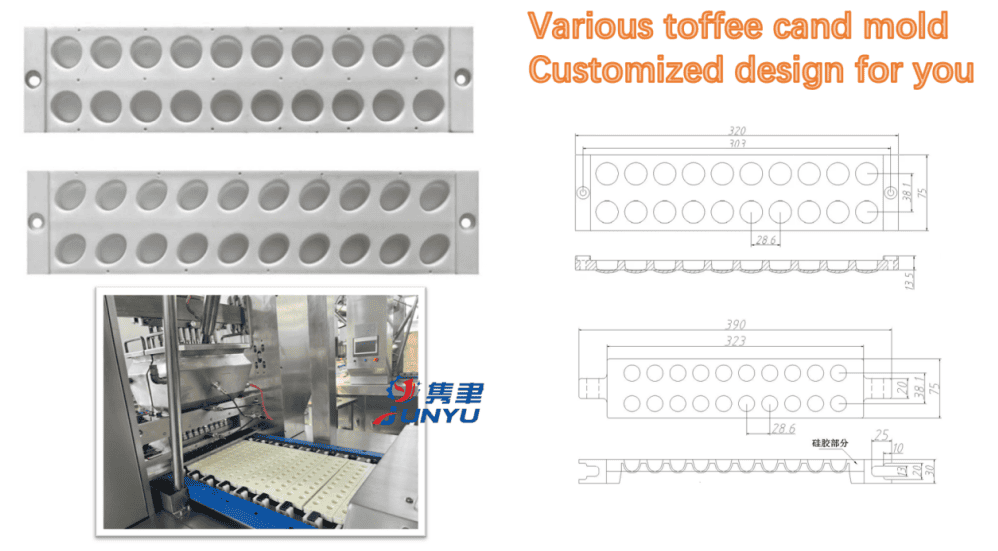

7. Mold Filling Inaccuracies

Inaccurate filling can result in uneven candies. Verify that the molds are clean and undamaged, and check the filling mechanism for any leaks or blockages.

8. Conveyor Belt Issues

Conveyor belts may sometimes slip or become misaligned. Ensure that the belts are properly tensioned, clean, and free of debris. Check the motor and pulleys for any signs of wear.

9. Demolding Difficulties

If candies are not releasing from the molds easily, it could be due to a variety of factors, including temperature, mold condition, or the release agent. Inspect molds for wear and ensure that the demolding mechanism is functioning correctly.

10. Cleaning and Sanitization

Buildup of residue can affect the machine’s performance. Regular cleaning and sanitization are necessary to maintain hygiene and ensure that the machine operates efficiently.

11. Pneumatic and Hydraulic Systems

Machines that use pneumatic or hydraulic systems may experience pressure-related issues. Check for leaks, and ensure that all components of these systems are functioning correctly.

12. Electrical and Control Systems

Issues with the electrical system or control panels can cause the machine to malfunction. Inspect for loose connections, damaged wires, or faulty control components.

13. Noise and Vibration

Unusual noise or vibration can indicate a problem with the machine’s operation. Identify the source of the noise and check for misaligned parts, imbalances, or worn components.

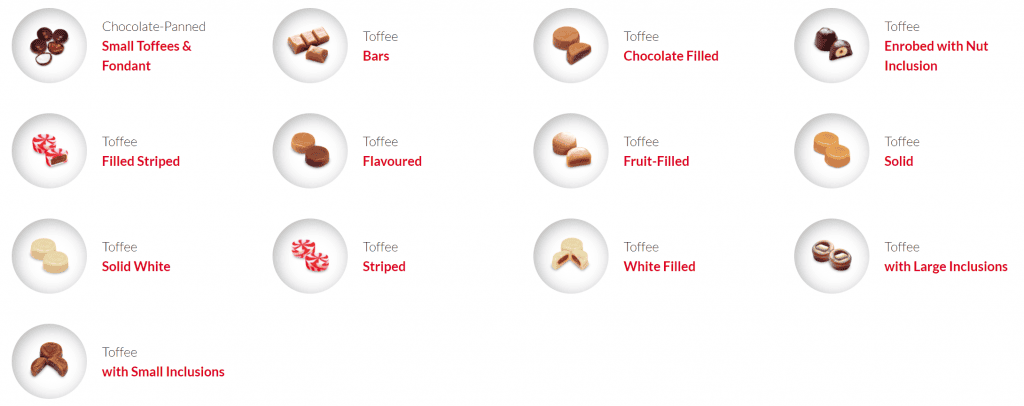

14. Product Quality Concerns

If the jelly candies are not meeting quality standards, it could be due to a variety of factors, including ingredient ratios, mixing times, or temperature settings. Review the recipe and production parameters to ensure they are correct.

15. Software and Control Interface

Modern machines often have software that controls the production process. Ensure that the software is up to date and free of glitches. If the machine uses a control interface, check for any errors or malfunctions.

16. Spare Parts and Replacements

Keep a stock of common spare parts and replacements on hand to quickly address any issues that may arise.

17. Training and Expertise

Ensure that operators are well-trained and knowledgeable about the machine. They should be able to identify common issues and perform basic troubleshooting.

18. Manufacturer Support

Utilize the support services provided by the machine’s manufacturer. They can offer guidance, technical support, and repair services when needed.

19. Professional Maintenance Services

Consider engaging professional maintenance services to perform regular checks and address more complex issues.

20. Troubleshooting Log

Keep a log of any issues encountered, along with the solutions applied. This can help in identifying recurring problems and their resolutions, making future troubleshooting more efficient.

Conclusión

Troubleshooting a Máquina para hacer caramelos de gelatina requires a combination of regular maintenance, a thorough understanding of the machine’s operation, and the ability to quickly identify and address issues as they arise. By following these tips and working closely with manufacturer support and professional services, you can minimize downtime and keep your confectionery production running smoothly.