Advantages of Effective Troubleshooting in Candy Production

Implementing effective troubleshooting techniques on a candy bar production line offers numerous advantages that enhance overall manufacturing performance and product quality.

Increased Production Efficiency

By quickly identifying and resolving issues such as equipment malfunctions or ingredient inconsistencies, manufacturers can minimize downtime and maintain a smooth production flow. This leads to higher operational efficiency and increased production capacity, allowing businesses to meet market demands more effectively.

Improved Product Quality and Consistency

Effective troubleshooting helps maintain consistent quality standards across all batches by addressing factors that cause variability, such as temperature fluctuations or improper ingredient mixing. This consistency strengthens consumer trust and satisfaction, which are vital for brand reputation and customer loyalty.

Extended Machinery Lifespan

Regular maintenance and timely resolution of equipment problems prevent excessive wear and unexpected breakdowns. Preventive maintenance, supported by troubleshooting insights, extends the machinery lifespan, reducing capital expenditures and ensuring reliable production operations.

Enhanced Food Safety and Compliance

By promptly addressing quality control failures and contamination risks, troubleshooting supports adherence to stringent food safety regulations and quality standards. This ensures product safety, minimizes recalls, and safeguards consumer health.

Cost Savings and Waste Reduction

Identifying root causes of production inefficiencies or defects reduces material waste, such as excess chocolate or spoiled batches. Efficient troubleshooting lowers repair costs and prevents costly production stoppages, contributing to overall cost savings.

Adaptability to Market Trends and Consumer Preferences

Effective troubleshooting allows manufacturers to swiftly adapt processes to incorporate functional ingredients, plant-based alternatives, or new formulations demanded by health-conscious consumers. This flexibility supports innovation and competitiveness in evolving markets.

Strengthened Workforce Competence

Ongoing staff training in troubleshooting techniques fosters a skilled workforce capable of proactive problem-solving. This reduces operator errors, improves operational efficiency, and promotes a culture of continuous improvement.

In summary, integrating comprehensive troubleshooting practices on a candy bar production line delivers significant advantages, including optimized production capacity, superior product safety, and enhanced consumer trust, all of which contribute to long-term business success.

Introduction to Candy Making

Candy making involves a complex production process that makes candy by transforming raw materials through specific techniques, requiring careful attention to detail and quality control measures to ensure consumer safety and satisfaction.

Understanding the manufacturing process and production stages is crucial for identifying and resolving issues on the candy production line.

The use of high-quality materials, such as cocoa butter and cocoa powder, is essential for maintaining product quality and meeting consumer expectations. There is a growing demand for innovative and healthier candy options, making it increasingly important to cater to health conscious consumers in candy making.

Proper lubrication and maintenance of machinery are also vital for ensuring smooth production and preventing downtime. Relying on outdated machinery can lead to increased downtime and inefficiency, highlighting the need for regular upgrades to maintain competitiveness and product quality.

Understanding Candy Production

The Science of Candy Production

- The production process involves a series of chemical reactions and physical changes that transform raw materials into a final product.

- Temperature control and heat distribution are critical factors in candy production, as they can affect the texture, consistency, and quality of the final product. Precise control of temperature, ingredient ratios, and processing times is essential to ensure uniformity and high product quality. Temperature fluctuations can lead to issues like sugar bloom and inconsistent texture.

- The use of candy molds and proper labeling are also important for ensuring that the final product meets consumer expectations and food safety regulations. Texture and consistency are key quality attributes; air bubbles can form during production, affecting the appearance and overall quality of the candy.

- Understanding the science behind candy production is essential for troubleshooting common issues and optimizing the production line. It is also important to maintain consistency in taste, texture, and appearance throughout the process.

Types of Candy Production

Hard Candy Production

- Hard candy production involves the use of sugar, corn syrup, and water to create a sugar solution that is heated to a specific temperature to produce a hard, glassy candy.

- The use of a candy thermometer is essential for ensuring that the sugar solution reaches the correct temperature and consistency.

- Proper cleaning and maintenance of equipment are also crucial for preventing contamination and ensuring consistent quality.

- The production of hard candies requires careful attention to detail and quality control measures to prevent issues such as sugar bloom and excess moisture.

Identifying Common Production Line Issues

Maintaining a smooth and efficient candy making process requires early identification of common production line issues. Problems such as equipment malfunctions, ingredient shortages, and lapses in quality control can disrupt the production process, leading to delays, reduced product quality, and increased operational costs. Regular monitoring of the production line is essential for spotting signs of trouble, such as inconsistent candy texture, unusual machine noises, or unexpected changes in output. Common issues include equipment breakdowns, ingredient contamination, and operator errors, all of which can compromise product quality. By implementing robust quality control measures and conducting frequent inspections, manufacturers can quickly identify and address these challenges, ensuring the production line continues to deliver high-quality candies that meet consumer expectations.

Troubleshooting Techniques and Tools

Effective troubleshooting techniques and tools are vital for maintaining candy quality and minimizing production line disruptions. Methods such as root cause analysis, fault tree analysis, and failure mode and effects analysis (FMEA) help teams systematically identify and resolve underlying issues. Utilizing specialized tools—like thermometers for precise temperature control, hygrometers for monitoring humidity, and spectrophotometers for assessing color consistency—enables real-time monitoring of critical factors that influence candy quality. Regular training ensures that production staff are proficient in using these troubleshooting tools and techniques, allowing for rapid diagnosis and correction of problems. This proactive approach helps maintain consistent quality and keeps the production line running efficiently.

Root Cause Analysis in Candy Production

Root cause analysis is a cornerstone of effective problem-solving in candy production processes. Rather than simply addressing surface-level symptoms, this approach digs deeper to uncover the fundamental reasons behind production line issues. By analyzing production data, consulting with staff, and conducting targeted experiments, manufacturers can pinpoint whether problems stem from equipment malfunctions, ingredient inconsistencies, or operator errors. Addressing these root causes leads to more sustainable solutions, improving both the efficiency and quality of the candy production process. Implementing root cause analysis as a standard practice helps manufacturers maintain high standards and prevent recurring issues, ensuring a reliable supply of high-quality candies.

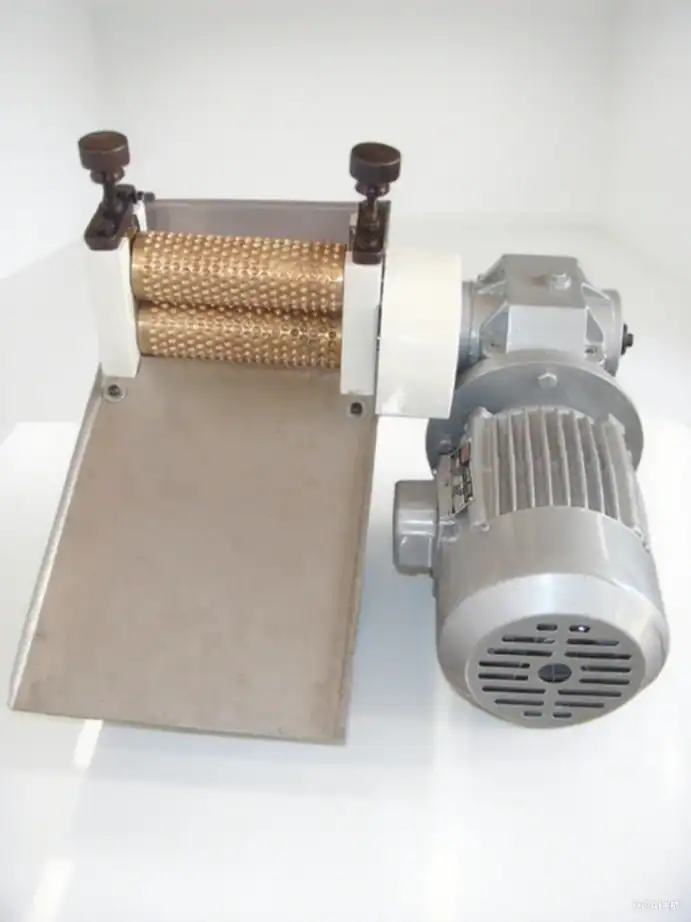

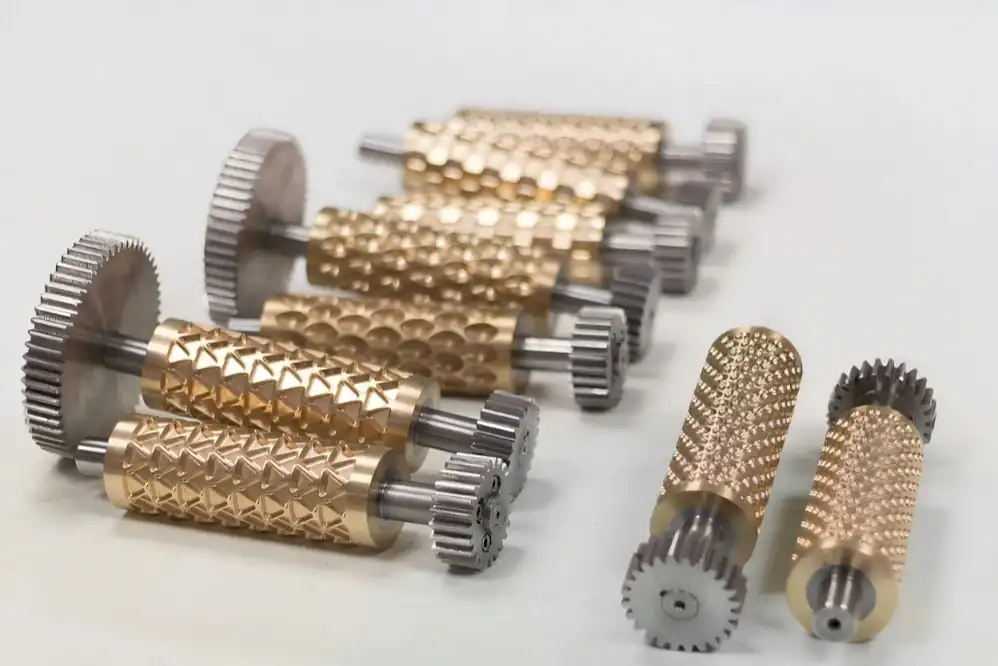

Preventative Maintenance for Equipment

Preventative maintenance is key to ensuring that candy production equipment operates at peak performance and meets consumer demands for consistent product quality. This involves scheduled inspections, thorough cleaning, proper lubrication, and timely replacement of worn components to keep machinery functioning correctly. Routine maintenance tasks help prevent unexpected breakdowns, reduce downtime, and extend the lifespan of production line equipment. By prioritizing preventative maintenance, manufacturers can minimize costly repairs, maintain product quality, and ensure the production line operates efficiently. This proactive approach not only supports smooth production cycles but also helps companies stay competitive by reliably meeting market demands.

Staff Training and Best Practices

Investing in staff training and the implementation of best practices is essential for maintaining high standards in candy production. Well-trained employees are better equipped to identify and resolve production line issues, operate machinery safely, and uphold rigorous quality control protocols. Adhering to standard operating procedures (SOPs), keeping detailed production records, and following established quality control measures all contribute to consistent product quality. Ongoing training and coaching sessions help staff stay updated on the latest industry standards and troubleshooting techniques, reducing the risk of operator error and enhancing overall production efficiency. By fostering a culture of continuous improvement and knowledge sharing, manufacturers can ensure their production lines consistently deliver high-quality candies that satisfy consumer expectations.

Ensuring Consumer Safety

Quality Control Measures

- Quality control measures are essential for ensuring consumer safety and satisfaction.

- Regular testing and inspection of raw materials, production processes, and final products are necessary for identifying and resolving issues. Inspecting the finished product before it moves to final packaging is crucial to ensure it meets all quality and safety standards.

- The use of real-time tracking systems and supply chain management can help to prevent supply chain disruptions and ensure that products meet food safety regulations. Final packaging plays a critical role in maintaining product quality, shelf life, and traceability throughout the supply chain.

- Allergen management and proper labeling are also critical for preventing allergic reactions and ensuring that products meet consumer expectations. Packaging design must balance aesthetic appeal with functionality and sustainability to attract consumers while protecting the product and supporting environmental goals.

Optimizing Production

Streamlining the Candy Production Line

- Streamlining the production line can help to improve operational efficiency, reduce costs, and increase productivity.

- The use of automated machinery and technology can help to improve consistency and quality, while also reducing labor costs and improving worker safety.

- Continuous improvement and customer satisfaction are essential for ensuring that products meet consumer demands and preferences.

- Market research and analysis of consumer trends can help to identify emerging trends and opportunities for growth and expansion.

Expanding into International Markets

Navigating Regulatory Requirements

- Expanding into international markets requires careful attention to regulatory requirements and food safety standards.

- Ensuring compliance with international regulations and standards is essential for preventing issues and ensuring consumer safety.

- The use of high-quality ingredients and proper labeling are critical for meeting consumer expectations and regulatory requirements.

- Understanding local market trends and consumer preferences is also essential for successful production and marketing of candy products.

Conclusion

- Troubleshooting common issues on a candy bar production line requires careful attention to detail and quality control measures.

- Understanding the production process, manufacturing process, and regulatory requirements is essential for ensuring consumer safety and satisfaction.

- The use of high-quality materials, proper lubrication, and maintenance of machinery are critical for ensuring smooth production and preventing downtime.

- Continuous improvement, customer satisfaction, and market research are essential for identifying emerging trends and opportunities for growth and expansion in the candy industry.