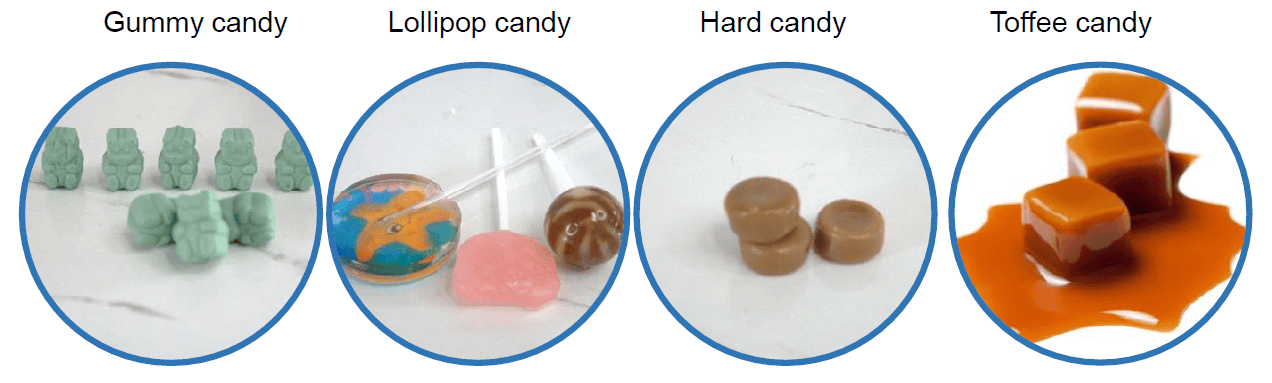

This starchless depositing system is designed for making molding-type candies.

It has a wide range of products such as Soft Gummy, Jelly, Toffee, Lollipop & Hard Candies with different cooking systems.

And A variety of styles such as center-filled, Cola Side by Side, Hamburger layer by layer, Tornado two or three colors…

Send us the photo of the candies you are interested in to start a customized production machine now!

| Model | JY-40 | JY-80 | JY-150 | JY-300 | JY-600 | JY-1500 |

| Capacity

PCS/H |

8,000-

12,000 |

12,000-

21,600 |

25,000-

43,200 |

50,000-

86,400 |

10,000-

172,800 |

384,000-

768,000 |

| Length |

Its unique, thin-film cooking process delivers consistent high quality across many types of sugar and sugar-free confectionery syrups for hard candy and lollipops.

A hinged rotor sweeps a thin, even film of syrup onto the inside of the tube where it cooks quickly With high output, high transparency of syrup for longer shelf life, and convenient operation, its is the First choice for high-quality candies.

This machine was advanced and suitable for cooking pectin, agar, carrageenan, and other modified starch for gummy production. Closed-loop cooking using temperature or pressure modes achieve an accurate final cooked temperature or moisture for shorter gummy drying time longer shelflife and fewer bubbles during the continuous process.

This is the cooker for Low Boiled Sweets such as soft and chewy candies, caramel, toffees, and fudges.

And Caramel Use A High-Efficiency Plate Heat Exchanger To Cook The Basic Sugar/ Glucose Pre-Mix, While Condensed Milk, Or Other Heat Sensitive Agents, Are Injected Into The Mass After The PHE And Then Cooked Inside A Caramelizing Vessel To Develop Desired Colour And Flavour. That Simple And Maintenance Free System Allows To Produce Premium Quality Toffees And Caramel With High Milk Content.

Three temper zoon with hot & cold chiller to control for the aerator machine during the mixing for better result of the aerating process.

Inside with dense mixing rod to high-speed rotary to achieve the desired density and structure.

This continuous vacuum microfilm cooker is used on milk candy, hard toffee, etc…

The difference is that will protect the Ingredients of dairy products from the high temperature from the normal cooker and keep the maximum dairy flavor.

Q1: I don’t have experience & formula can you help?

-A: Yes, we are offering a full scope plan from formula to product support

Q2: Can I make hard candy on this machine?

-A: Yes, but also taffy candy, lollipops too.

Q3: What’s the machine voltage and Amp?

-A: We customize the equipment according to your voltage, and with different voltages, we will calculate the ampere list for you.

Q4:I want to add a pharmacy inside the candies does your machine has any certificate to help me pass the FDA requirements?

-A: Yes, We have CE and used all brands by UL&EU listed in strict accordance with GMP Stander.

Q5:What else do I need to prepare does this machine need clean compressed air?

-A: C onside most of the customer’s space limit this machine only need to connect the power, save customer’s cost and complex evolution of compress airflow. Use servo more simple & smart control no need connect extra systems for the machines.

Q6: How should I set the temperature and candy weight?

-A: By control box and touch screen setting to adjust.

Q7: Do I need to move the molds to the cooling step?

-A: No, the machine is fully automatic from the depositor and cool, you only need to collect the candy, and the machine exit!

Q8: Do I need some expert to install the machine?

-A: Machine electrical is by the quick coupler and easy setting on a touch screen like a smartphone or if you need we have local technical support team can help.

We Provide a Nutrition gummy bear candy-making machine,If you are interested in Nutrition gummy bear candy-making machine,You can browse related products and initiate consultations on our website.