O melhor Linha de produção de biscoitos: Considerações sobre eficiência e design para fabricantes do Reino Unido

O setor de biscoitos do Reino Unido está experimentando um crescimento sem precedentes, com os consumidores britânicos gastando mais de £2,8 bilhões anualmente em biscoitos. Não importa se você é uma padaria iniciante em Manchester ou um fabricante estabelecido em Birmingham, investir no equipamento certo é uma tarefa difícil. linha de produção de biscoitos pode transformar suas operações comerciais e aumentar significativamente sua vantagem competitiva nesse mercado próspero.

Linhas de produção de biscoitos desempenham um papel crucial no setor de alimentos em geral, permitindo a fabricação de alimentos em larga escala com qualidade e eficiência consistentes.

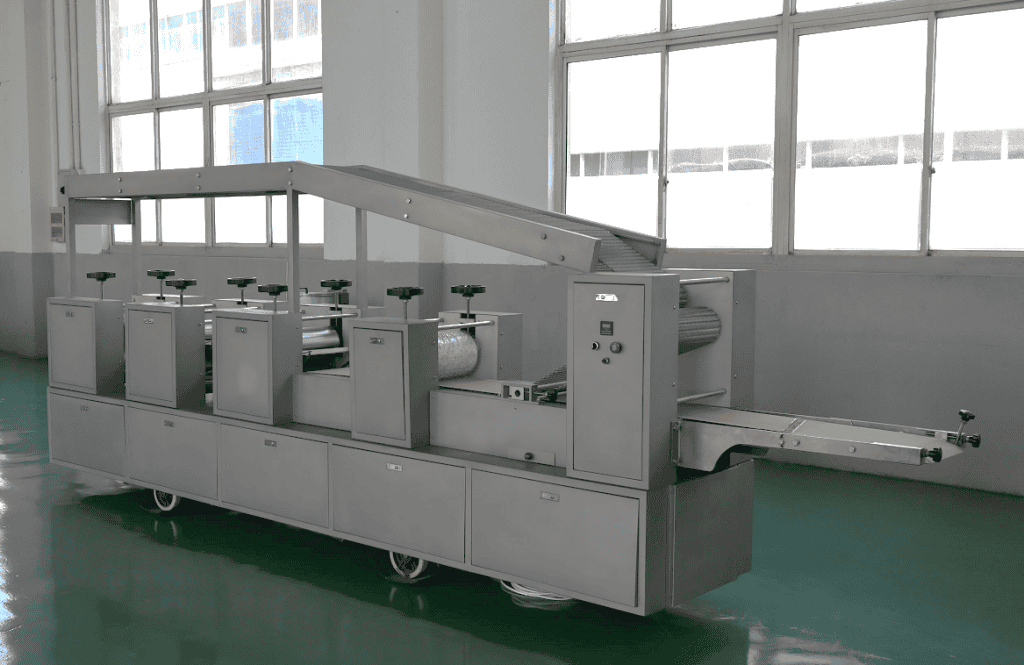

Uma linha de produção de biscoitos moderna representa muito mais do que um simples maquinário - é o coração de sua operação de fabricação, orquestrando cada etapa, desde os ingredientes brutos até os produtos perfeitamente embalados que enfeitam as mesas de chá britânicas em todo o país.

Introdução à fabricação de biscoitos

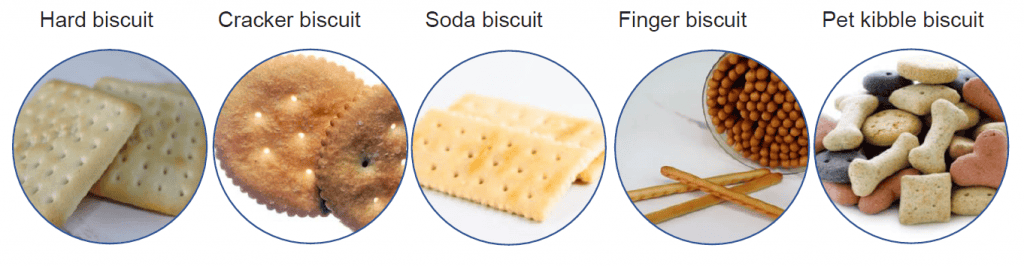

A fabricação de biscoitos no moderno setor de processamento de alimentos é um processo sofisticado que depende de maquinário especializado e linhas de produção cuidadosamente coordenadas. Um típico linha de produção de biscoitos A linha de produção de biscoitos consiste em vários estágios principais, incluindo mistura, formação de massa, cozimento e embalagem, cada um deles projetado para garantir a produção eficiente de biscoitos em grande escala. Essas linhas de produção são projetadas para atender a requisitos específicos de produção, permitindo que os fabricantes produzam uma gama diversificada de tipos de biscoitos, como biscoitos duros, biscoitos macios e biscoitos tipo sanduíche. Ao utilizar equipamentos e máquinas avançados, as empresas podem agilizar o processo de fabricação de biscoitos, manter a alta qualidade do produto e responder com flexibilidade às mudanças nas demandas do mercado. Seja na produção de biscoitos duros clássicos, biscoitos macios indulgentes ou biscoitos sanduíche inovadores, uma linha de produção bem projetada é essencial para fornecer resultados consistentes e apoiar o crescimento do negócio de produção de biscoitos no setor de processamento de alimentos.

Compreensão Linhas de produção de biscoitos no mercado do Reino Unido

A base de qualquer operação bem-sucedida de fabricação de biscoitos está na compreensão do que constitui um sistema de produção eficaz. A linha de produção de biscoitos compreende uma série sofisticada de máquinas e equipamentos interconectados, projetados para produzir biscoitos em escala industrial, mantendo a qualidade excepcional do produto e minimizando o desperdício em toda a jornada de processamento de alimentos.

Uma empresa especializada em biscoitos linhas de produção pode fornecer soluções personalizadas e orientação especializada aos fabricantes, garantindo que cada linha de produção atenda às necessidades comerciais e às metas operacionais específicas.

Os principais fatores que influenciam o design e a eficácia de um linha de produção de biscoitos incluem o projeto do produto, os requisitos de maquinário, a capacidade de produção, o espaço disponível, o fluxo de materiais e a segurança dos funcionários.

Componentes principais dos sistemas de produção modernos

Os estágios a seguir são componentes essenciais de um sistema moderno linha de produção de biscoitos:

- Estações de mistura e preparação que garantem a qualidade consistente da massa

- Equipamentos de modelagem e conformação para criar formas uniformes de biscoitos

- Sistemas de cozimento com controles precisos de temperatura e tempo

- Áreas de resfriamento e acabamento para o condicionamento ideal do produto

- Máquinas de embalagem para manter o frescor e o apelo nas prateleiras

Esses sistemas integrados são particularmente cruciais para as empresas do Reino Unido que buscam aumentar sua capacidade de produção e, ao mesmo tempo, atender aos rigorosos padrões britânicos de segurança alimentar e às expectativas de qualidade dos consumidores.

O fabricante da linha de produção que você escolher desempenha um papel fundamental no projeto e na instalação de um sistema de última geração que se alinhe aos seus requisitos operacionais específicos e às suas ambições de crescimento.

O processo completo de fabricação de biscoitos

Métodos tradicionais versus automação moderna

A evolução da fabricação de biscoitos no Reino Unido foi notável. A fabricação tradicional de biscoitos envolvia processos que exigiam muita mão de obra, mas os atuais linhas de produção de biscoitos incorporam automação avançada que revoluciona a eficiência.

Automação em ambientes modernos linhas de produção de biscoitos reduz significativamente os erros humanos, minimizando a intervenção manual, o que resulta em melhor qualidade do produto, segurança e eficiência operacional.

O processo contemporâneo de fabricação de biscoitos segue uma sequência cuidadosamente orquestrada:

- Mistura e amassamento iniciais dos ingredientes da massa usando misturadores de precisão

- Modelagem e formação por meio de moldadores rotativos ou sistemas de corte

- Cozimento controlado em fornos de túnel com perfis de temperatura consistentes

- Resfriamento sistemático em sistemas de transportadores para o desenvolvimento ideal da textura

Versatilidade na linha de produtos

As linhas de produção modernas se destacam por sua adaptabilidade. Uma única linha de produção de biscoitos pode ser configurado para produzir:

- Biscoitos digestivos tradicionais adorados pelos consumidores britânicos

- Biscoitos de massa macia com texturas delicadas

- Biscoitos duros que exigem ciclos de cozimento prolongados

- Biscoitos tipo sanduíche com recheio de creme ou geleia

- Biscoitos artesanais para segmentos de mercado premium

- Biscoitos salgados para diversas preferências dos consumidores

Muitos fabricantes também investem em linhas de produção de biscoitos para expandir ainda mais suas ofertas de produtos e atender à crescente demanda por biscoitos e produtos de panificação relacionados.

Os fornos de túnel e os sofisticados sistemas de esteira transportadora asseguram que cada tipo de produto receba condições ideais de processamento, garantindo uma qualidade consistente em toda a sua linha.

Seleção estratégica de equipamentos para fabricantes do Reino Unido

Componentes críticos de maquinário

A seleção de equipamentos adequados é a base de qualquer operação bem-sucedida de produção de biscoitos. Os fabricantes britânicos devem considerar vários fatores essenciais ao desenvolver suas capacidades de produção:

Equipamento de produção primária:

- Misturadores de massa de alta capacidade com controles de velocidade variável

- Moldadores rotativos de precisão para modelagem consistente

- Fornos de cozimento em túnel com eficiência energética

- Transportadores de resfriamento avançados para condicionamento adequado

- Máquinas de embalagem essenciais que automatizam o estágio final do processo de produção de biscoitos, garantindo eficiência, consistência e qualidade dos produtos acabados

O processo de seleção de equipamentos requer uma análise cuidadosa de sua linha de produtos pretendida, dos volumes de produção almejados e dos requisitos específicos de qualidade que se alinham às expectativas dos consumidores britânicos.

Seleção de equipamentos para biscoitos duros

A produção de biscoitos duros requer uma linha de produção equipada com maquinário projetado especificamente para esse tipo de biscoito. O processo começa com um robusto misturador de massa, que garante que todos os ingredientes sejam completamente combinados para criar uma massa uniforme. Em seguida, um moldador rotativo molda a massa em formas precisas, proporcionando a consistência e a definição pelas quais os biscoitos duros são conhecidos. A massa moldada vai então para um forno túnel, onde as condições controladas de cozimento proporcionam a crocância e a textura perfeitas. Para melhorar ainda mais a qualidade do produto, um transportador de resfriamento é usado após o cozimento, permitindo que os biscoitos esfriem uniformemente e mantenham sua estrutura e aparência. A seleção do equipamento certo para cada estágio é crucial para a produção de biscoitos duros com qualidade de produto consistente, o que torna essencial que os fabricantes invistam em maquinário adaptado às suas necessidades específicas de produção.

Considerações sobre a linha de produção de crackers

Embora as linhas de produção de crackers tenham semelhanças com as linhas tradicionais de produção de linhas de produção de biscoitos, Por isso, eles exigem considerações exclusivas para obter a textura e o sabor desejados. O processo de produção de crackers começa com uma batedeira capaz de lidar com as formulações específicas de massa necessárias para crackers. Em seguida, uma máquina de laminação enrola a massa na espessura exata necessária, seguida de um forno que garante o cozimento uniforme e a crocância característica dos crackers. Para maximizar a capacidade e a eficiência da produção, é importante selecionar máquinas que atendam aos requisitos específicos da produção de biscoitos. Os sistemas automatizados desempenham um papel fundamental na redução dos custos de mão de obra e na minimização do desperdício, além de oferecer uma qualidade consistente do produto. Ao se concentrarem em processos de produção eficientes e investirem nos equipamentos certos, os fabricantes podem otimizar suas linhas de produção de crackers para obter qualidade e economia.

Personalização e flexibilidade

Os principais fabricantes de equipamentos do Reino Unido oferecem máquinas especializadas projetadas especificamente para as demandas do mercado britânico. Esses sistemas podem acomodar larguras de trabalho variadas e incorporar componentes importantes, como:

- Esteiras transportadoras de velocidade variável para diferentes tipos de produtos

- Sistemas de resfriamento modulares para otimização do espaço

- Configurações flexíveis de embalagem para diversos requisitos de varejo

O investimento em equipamentos de qualidade rende dividendos por meio da redução dos custos de manutenção, do aumento da eficiência energética e da consistência aprimorada do produto que os consumidores britânicos esperam.

Otimização em larga escala Linhas de produção de biscoitos

Considerações sobre eficiência para operações no Reino Unido

A produção em larga escala no competitivo mercado britânico exige atenção meticulosa à eficiência operacional. Os fabricantes bem-sucedidos se concentram em várias áreas críticas:

Métricas de eficiência de produção:

- Minimização dos tempos de troca entre as execuções do produto

- Maximização das taxas de utilização dos equipamentos

- Redução do consumo de energia por unidade produzida

- Otimização da alocação de mão de obra nos turnos de produção

A produção em massa de biscoitos requer uma abordagem completa e integrada que englobe todos os aspectos, desde o manuseio da matéria-prima até a embalagem final. Os fabricantes britânicos se beneficiam especialmente dos sistemas projetados para reduzir o desperdício e, ao mesmo tempo, manter os padrões de alta qualidade que os consumidores do Reino Unido exigem.

Garantia de qualidade em operações de alto volume

Um projeto bem elaborado linha de produção de biscoitos incorpora medidas de controle de qualidade em todas as etapas:

- Verificação automatizada de peso para tamanhos de porções consistentes

- Monitoramento da temperatura durante todo o processo de cozimento

- Sistemas de inspeção visual para identificar defeitos

- Verificação da integridade da embalagem antes da distribuição

Essas medidas de qualidade não apenas garantem a conformidade com as normas de segurança alimentar do Reino Unido, mas também protegem a reputação de sua marca no competitivo mercado britânico.

Linha de produção de biscoitos Layout e design

Um sistema eficiente linha de produção de biscoitos O layout é fundamental para alcançar altos níveis de produtividade e qualidade do produto. O projeto deve priorizar o fluxo suave de materiais e produtos, minimizando o desperdício e reduzindo os custos de mão de obra por meio da colocação estratégica de máquinas como misturadores de massa, moldadores rotativos e fornos de túnel. A incorporação de uma máquina de embalagem no final da linha garante que os biscoitos sejam embalados de forma rápida e higiênica, prontos para a distribuição. Para aumentar ainda mais a eficiência da produção, o layout deve ser otimizado para automação, reduzindo a necessidade de intervenção manual e permitindo uma operação contínua. A flexibilidade também é fundamental - as opções de personalização devem ser incorporadas ao projeto para acomodar diferentes tipos e sabores de biscoitos, garantindo que a linha de produção possa se adaptar aos requisitos específicos de produção e às tendências do mercado. Ao se concentrarem nesses princípios de projeto, os fabricantes podem criar um ambiente de produção que suporte tanto a alta produção quanto a qualidade superior do produto.

Projetando seu projeto ideal Linha de produção de biscoitos

Estratégia de planejamento e implementação

A criação de um sistema de produção eficaz requer um planejamento abrangente que atenda aos seus objetivos comerciais específicos. As principais considerações incluem:

Planejamento da capacidade de produção:

- Análise da demanda do mercado atual

- Projeções de crescimento futuro

- Acomodação com variação sazonal

- Potencial de diversificação de produtos

Requisitos operacionais:

- Espaço disponível e restrições de layout

- Requisitos de serviços públicos e necessidades de infraestrutura

- Programas de treinamento de pessoal e desenvolvimento de habilidades

- Sistemas de suporte e programação de manutenção

Trabalho com fabricantes de linhas de produção

A implementação bem-sucedida depende muito da parceria com fabricantes experientes que entendam os requisitos exclusivos da produção britânica de biscoitos. O fabricante ideal deve fornecer:

- Serviços abrangentes de consultoria de design

- Suporte para instalação e comissionamento

- Programas de treinamento técnico contínuo

- Serviços de manutenção e suporte responsivos

Técnicas avançadas de otimização do fluxo de trabalho

Simplificação dos processos de produção

A otimização do fluxo de trabalho representa um fator crítico para maximizar seu linha de produção de biscoitos eficiência. Os fabricantes britânicos alcançam os melhores resultados por meio de:

Estratégias de aprimoramento de processos:

- Implementação dos princípios da manufatura enxuta

- Redução de gargalos por meio do balanceamento de capacidade

- Minimização dos tempos de manuseio e transferência de materiais

- Otimização dos procedimentos de troca entre produtos

Integração de tecnologia:

- Sistemas de controle automatizados para operações consistentes

- Monitoramento e coleta de dados em tempo real

- Programação de manutenção preditiva

- Integração com sistemas de planejamento de recursos empresariais

Manutenção da vantagem competitiva

No dinâmico mercado de biscoitos do Reino Unido, a excelência operacional distingue os fabricantes bem-sucedidos. Os principais indicadores de desempenho incluem:

- Porcentagens de eficácia geral do equipamento (OEE)

- Taxas de qualidade na primeira passagem

- Consumo de energia por quilograma produzido

- Métricas de produtividade da mão de obra

Sistemas abrangentes de controle de qualidade

Normas e regulamentos britânicos

Os fabricantes de biscoitos do Reino Unido devem obedecer a rigorosos padrões de qualidade e segurança. Eficaz linhas de produção de biscoitos incorporar medidas abrangentes de controle de qualidade:

Conformidade regulatória:

- Implementação do sistema de gerenciamento de segurança de alimentos

- Requisitos de rastreabilidade em toda a produção

- Controle de alérgenos e prevenção de contaminação cruzada

- Minimização do impacto ambiental

Monitoramento da qualidade:

- Implementação do controle estatístico de processos

- Calibração regular do equipamento de medição

- Procedimentos sistemáticos de amostragem e teste

- Sistemas de integração de feedback do cliente

Cultura de melhoria contínua

Os principais fabricantes britânicos adotam filosofias de melhoria contínua que promovem aprimoramentos contínuos em suas operações de produção. Essa abordagem inclui:

- Revisões regulares de desempenho e oportunidades de otimização

- Esquemas de sugestões da equipe para melhorias operacionais

- Benchmarking em relação às melhores práticas do setor

- Investimento em tecnologias emergentes e inovações

Manutenção essencial e suporte operacional

Estratégias de manutenção preventiva

Manter o desempenho ideal de seu linha de produção de biscoitos requer abordagens de manutenção sistemática que minimizem o tempo de inatividade e, ao mesmo tempo, garantam uma produção de qualidade consistente.

Planejamento de manutenção:

- Programas de manutenção preventiva programada

- Sistemas de monitoramento baseados em condições

- Gerenciamento de estoque de peças de reposição críticas

- Procedimentos de resposta a emergências

Treinamento e desenvolvimento:

- Programas de desenvolvimento de habilidades do operador

- Recursos de solução de problemas técnicos

- Implementação do protocolo de segurança

- Procedimentos de garantia de qualidade

Sucesso operacional de longo prazo

O sucesso sustentável no setor de fabricação de biscoitos do Reino Unido exige um compromisso contínuo com a excelência operacional. Isso inclui:

- Atualizações e modernizações regulares dos equipamentos

- Treinamento e desenvolvimento contínuos da equipe

- Análise de tendências de mercado e recursos de adaptação

- Planejamento estratégico para oportunidades de crescimento futuro

Vantagens das linhas completas de produção de biscoitos

Investimento completo linhas de produção de biscoitos oferece uma série de benefícios importantes para os fabricantes que desejam se destacar no negócio de produção de biscoitos. Esses sistemas totalmente integrados foram projetados para proporcionar o máximo de eficiência na produção, automatizando todas as etapas do processo, desde a mistura e a formação até o cozimento e a embalagem. Como resultado, os fabricantes podem obter biscoitos de maior qualidade com padrões de produto consistentes, além de reduzir os custos de mão de obra e minimizar a intervenção manual. As linhas completas são projetadas para reduzir o desperdício e otimizar o uso de recursos, apoiando tanto a eficiência de custos quanto as metas de sustentabilidade. Os principais fabricantes oferecem uma variedade de linhas completas de produção de biscoitos, incluindo opções para linhas de produção de biscoitos macios e linhas de produção de biscoitos duros, garantindo que os requisitos específicos de produção sejam atendidos. Para As empresas que buscam aumentar a eficiência, melhorar a qualidade do produto e manter uma vantagem competitiva, as linhas completas de produção de biscoitos representam um investimento inteligente e preparado para o futuro.

Conclusão

Investir em um linha de produção de biscoitos rrepresenta uma decisão transformadora para os fabricantes do Reino Unido que buscam se destacar no competitivo mercado britânico. Desde a seleção inicial do equipamento até a otimização operacional contínua, cada aspecto do seu sistema de produção contribui para o seu sucesso a longo prazo.

O segredo para alcançar resultados excepcionais está na parceria com fabricantes experientes, na implementação de sistemas abrangentes de controle de qualidade e na manutenção de um compromisso com a melhoria contínua que acompanha a evolução das demandas dos consumidores e as inovações do setor.

Pronto para transformar sua operação de fabricação de biscoitos? Entre em contato hoje mesmo com os principais especialistas em linhas de produção do Reino Unido para discutir suas necessidades específicas e descobrir como o investimento correto em equipamentos pode impulsionar sua empresa a novos patamares de sucesso no próspero mercado britânico de biscoitos.