Fonte da imagem: não exibir

Uma máquina de balas de goma em 2025 tem sensores inteligentes, IA e visão computacional. Isso ajuda a produzir balas de goma rapidamente e com boa precisão. Você pode ver essas máquinas em residências, lojas de doces e grandes fábricas. Os novos modelos permitem que você assista à produção em seu telefone. Você também pode fazer pacotes especiais de gomas para diferentes dietas. Muitas pessoas usam essas máquinas porque elas cometem menos erros. Elas economizam energia e ajudam a fazer guloseimas divertidas e especiais com menos trabalho.

Principais conclusões

Máquinas de balas de goma em 2025 têm sensores inteligentes e automação. Elas produzem doces mais rapidamente e com menos erros. Há três tipos principais de máquinas. As máquinas domésticas produzem pequenos lotes. As máquinas comerciais são para lojas. As máquinas industriais são para grandes fábricas. As novas máquinas têm recursos de segurança, como moldes antiaderentes. Elas também têm sensores que param a máquina se houver algum problema. Os controles inteligentes ajudam a alterar as configurações facilmente. Eles mantêm os gummies sempre com o mesmo sabor. Antes de comprar, pense em suas necessidades, orçamento e espaço. Sempre verifique as avaliações e peça demonstrações, se possível.

Como eles funcionam

Processo principal

Para usar um máquina de balas de gomaPara a máquina, você precisa de algumas peças principais. A máquina tem um sistema que aquece e mistura as coisas. Ela derrete açúcar, gelatina e outras coisas. Você coloca a mistura dentro dela e a máquina a aquece. Em seguida, a mistura quente vai para o local de preenchimento do molde. Lá, o líquido preenche os moldes que dão forma às balas de goma.

Depois disso, um transportador move os moldes pela máquina. A parte de resfriamento resfria os moldes. Isso faz com que as gomas fiquem firmes e fáceis de tirar. Algumas máquinas usam moldes de amido, mas outras usam moldes de silicone ou plástico. Os moldes de amido deixam as gomas macias, mas os de silicone e plástico são mais fáceis de limpar. Em 2025, a maioria das máquinas tem superfícies antiaderentes e revestimentos especiais. Elas ajudam a manter as gomas seguras e facilitam a limpeza.

Dica: Os moldes sem amido são populares atualmente. Eles mantêm os gummies limpos e ajudam a máquina a durar mais.

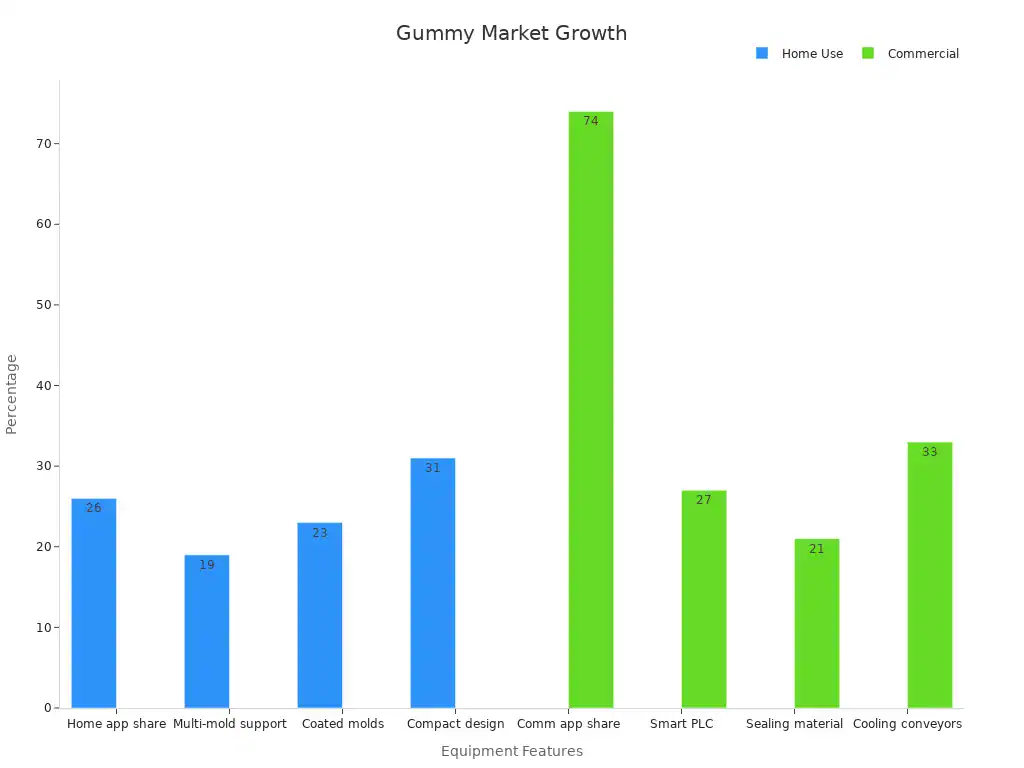

Você pode ver como as coisas mudaram no gráfico abaixo. As máquinas domésticas agora fazem mais formas e usam moldes mais seguros. As máquinas comerciais se concentram na velocidade e em manter as coisas limpas.

Automação

As máquinas de balas de goma atuais usam tecnologia inteligente para ajudar você. Há sensores e câmeras dentro da máquina. Eles verificam a temperatura, contam as balas de goma e detectam problemas. A máquina pode se consertar sozinha se algo estiver errado. Isso significa menos erros e gomas melhores.

É possível usar uma tela sensível ao toque ou um telefone para controlar muitas máquinas. Algumas máquinas usam robôs para mover moldes e embalar gomas. Na Europa, as empresas de alimentos usam mais robôs atualmente. O número de robôs nas fábricas de alimentos aumentou de 75 em 2020 para 110 em 2025. Isso ajuda as fábricas a produzir mais gomas com menos trabalho.

Avanço tecnológico | Evidência numérica | Descrição do impacto |

|---|---|---|

Sensores inteligentes | N/A | Melhore a precisão e a eficiência detectando materiais estranhos durante a produção |

Dispositivo SiMoGel | Substitui os moguls de amido por silicones e blisters para acelerar a produção de gomas |

A automação também ajuda na contagem e no empacotamento. Algumas máquinas podem embalar de 200 a 300 pacotes de gomas por minuto. Isso é muito mais rápido do que nas máquinas antigas. A automação reduz os erros em cerca de 35%. Você pode confiar que a máquina fará gomas do mesmo tamanho e formato todas as vezes.

Segurança

A segurança é muito importante na fabricação de gomas. As novas máquinas usam revestimentos e materiais especiais para manter os alimentos seguros. Muitas máquinas domésticas têm moldes revestidos com produtos para cicatrização de feridas. Esses moldes não grudam e são fáceis de limpar. As máquinas comerciais usam selos para impedir a entrada de germes.

As máquinas modernas têm sensores para verificar se há problemas. Se a máquina ficar muito quente ou se algo estiver errado, ela para e avisa você. Isso mantém você e seus gummies seguros. Algumas máquinas têm sistemas de limpeza no local. Eles lavam a parte interna sem desmontar a máquina.

Observação: Certifique-se sempre de que sua máquina de balas de goma siga as regras de segurança alimentar. Isso mantém você saudável e as balas de goma com bom sabor.

Tipos de máquinas de balas de goma

Uso doméstico

Atualmente, muitas pessoas têm em suas cozinhas máquinas de fazer balas de goma para uso doméstico. Máquinas como a LĒVO e a Magical Gummy Maker ajudam você a fazer pequenas quantidades de gomas. A maioria das máquinas domésticas é fácil de usar. Basta adicionar os ingredientes, pressionar um botão e aguardar a finalização das gomas. Cada lote geralmente rende de uma a cinco xícaras. As pessoas usam essas máquinas para lanches ou para fazer gomas com vitaminas ou CBD.

Algumas pessoas gostam do fato de essas máquinas serem simples e fáceis. Por exemplo, SammyB diz que o LĒVO é ótimo para microdosagem. Mas Curtis Cybenko teve problemas com a máquina e seu aplicativo. O gráfico abaixo mostra o que os usuários pensam sobre as máquinas de uso doméstico:

Dica: Verifique as avaliações antes de comprar uma máquina de balas de goma para uso doméstico. Algumas máquinas são melhores para pequenos lotes ou dietas especiais.

Comercial

Máquinas comerciais de balas de goma são boas para lojas de doces e pequenas fábricas. Essas máquinas podem produzir centenas ou milhares de balas de goma por hora. São usadas telas sensíveis ao toque e sensores inteligentes para controlá-las. A automação ajuda a fazer com que cada lote seja igual. Muitas máquinas comerciais têm sistemas de segurança. Esses sistemas ajudam a economize até 25% de ingredientes e deixe os clientes mais satisfeitos em 30% porque toda goma tem o mesmo sabor.

Descrição da estatística | Impacto/valor |

|---|---|

Redução do desperdício de ingredientes | Economia de até 25% |

Efeito no sabor e na textura | Sem compromisso |

Aumento da satisfação do cliente | Aumento de 30% devido ao sabor consistente e ao desempenho do produto |

Capacidade de produzir gomas fortificadas | Permite a distribuição precisa de vitaminas, minerais ou CBD |

Conformidade com os regulamentos | Garante os benefícios terapêuticos e a adesão aos regulamentos |

Você pode encontrar máquinas comerciais em lojas de doces, empresas de alimentos e algumas farmácias. O mercado americano para essas máquinas está crescendo rapidamente. Em 2024, seu valor era de $0,4 bilhão e poderia chegar a $0,7 bilhão em 2033.

Industrial

As máquinas industriais de balas de goma funcionam em grandes fábricas. Essas máquinas podem produzir dezenas de milhares de balas de goma por hora. Elas usam automação avançada, robôs e verificações em tempo real. As máquinas industriais ajudam as grandes empresas a atender à alta demanda e a seguir as regras de segurança. Elas usam sistemas inteligentes para contar, embalar e verificar cada goma. Isso mantém os produtos seguros e ajuda a marca.

As máquinas industriais podem produzir vários formatos, cores e sabores. Elas também ajudam a adicionar vitaminas ou medicamentos às gomas com muita precisão. Se você precisar fazer muitas gomas, uma máquina industrial de balas de goma é a melhor opção.

Recursos

Controles inteligentes

A maioria dos novos máquinas de balas de goma usam telas sensíveis ao toque ou telefones para controle. Você pode definir a temperatura, a velocidade da mistura e a quantidade a ser despejada. Os sensores observam cada passo e enviam alertas se houver algum problema. Esses controles inteligentes o ajudam a trabalhar mais rápido e a cometer menos erros.

A máquina mantém o xarope na temperatura certa para o bom gosto.

Ele verifica a temperatura e a quantidade de vazamento o tempo todo.

É possível alterar as configurações facilmente com a tela sensível ao toque.

A máquina usa dados para ajudá-lo a obter melhores resultados posteriormente.

Dica: Os controles inteligentes ajudam as gomas a terem o mesmo sabor todas as vezes.

Eficiência energética

A economia de energia é importante se você usa muito a máquina. As novas máquinas aquecem apenas o que você precisa, portanto, usam menos energia. Elas resfriam os gummies rapidamente, o que também economiza energia. Algumas máquinas têm partes que podem ser desligadas quando não forem necessárias.

Recurso tecnológico | Descrição | Dados de desempenho/benefícios |

|---|---|---|

Usa a agitação para mover gomas e classificá-las por tamanho e forma. | Menos erros de contagem e menos energia utilizada. | |

Sistemas pneumáticos | Empurra as balas de goma para as caixas sem muito trabalho das pessoas. | Menos trabalho manual e menor consumo de energia. |

Integrações futuras (IA, IoT) | Observa e aprimora o processo à medida que ele acontece. | Deve fazer com que as máquinas funcionem melhor e usem menos energia. |

Personalização

Você pode fazer vários tipos de gomas com essas máquinas. Altere o molde para obter novas formas ou usar kits extras para obter mais sabores. Você também pode mover partes da máquina para adaptá-la ao seu espaço.

Escolha entre vários moldes para criar formas especiais.

Adicione coisas como óleo ou açúcar por cima.

Configure a máquina para lotes pequenos ou grandes.

Essas opções ajudam você a seguir novas tendências ou a dar aos clientes o que eles querem.

Aprimoramentos de segurança

A segurança é muito importante para máquinas de balas de goma. As máquinas agora têm tampas e selos especiais para impedir a entrada de germes. Elas verificam se há problemas com tamanho, cor ou embalagem. Se algo estiver errado, a máquina para e avisa.

Observação: Certifique-se sempre de que sua máquina siga as normas de segurança alimentar, como ISO ou GMP. Isso mantém seus gummies seguros e bons para comer.

Escolha de uma máquina de balas de goma

Avaliação das necessidades

Primeiro, pense no que você quer fazer. Você precisa de apenas algumas gomas ou de muitas para uma empresa? Verifique aspectos como temperatura de cozimento e quantos gummies a máquina produz pode fazer. Observe também os recursos de automação que ele possui. O blog Goldsupplier diz As máquinas automáticas são melhores para a produção de grandes lotes. Elas economizam tempo e ajudam você a cometer menos erros. As máquinas manuais custam menos dinheiro. Você tem mais controle, mas leva mais tempo para fazer cada lote. A Sinofude Technology diz para verificar se você precisa de coisas especiais, como dosagem exata ou túneis de resfriamento. Sempre escolha uma máquina que se adapte ao que você precisa fazer.

Dica: Anote quantas gomas você quer fazer por dia. Isso o ajudará a escolher a máquina certa.

Orçamento

Planeje seu orçamento antes de comprar uma máquina. A Gondor Machinery diz para pensar no preço, além dos custos de conserto, energia e mão de obra. As máquinas pequenas custam menos no início. Máquinas maiores podem economizar dinheiro se você fizer muitas gomas. Verifique se a máquina ajudará você a recuperar o que gastou.

Tipo de máquina | Faixa de custo (USD) |

|---|---|

$10,000 – $30,000 | |

Linha de produção automática de ursinhos de goma | $60,000 – $160,000 |

Linha de produção de ursinhos de goma totalmente automática | $120,000 – $280,000 |

Espaço

Meça seu espaço antes de comprar uma máquina. As máquinas domésticas cabem em um balcão de cozinha. As máquinas comerciais e industriais precisam de mais espaço. Certifique-se de que haja espaço para misturar, moldar e resfriar. Deixe espaço extra para limpeza e movimentação. Se quiser expandir seus negócios, pense na possibilidade de precisar de mais espaço posteriormente.

Máquinas domésticas: cabem na maioria das cozinhas

Máquinas comerciais: precisam de uma pequena sala ou área de trabalho

Máquinas industriais: precisam de um espaço amplo e aberto

Marcas

Há muitas marcas que vendem máquinas de balas de goma. Algumas marcas fabricam máquinas para uso doméstico. Outras fabricam máquinas para grandes fábricas. Escolha marcas com boas avaliações e suporte útil. Veja se a marca oferece treinamento, peças de reposição e ajuda na configuração. Em 2025, as marcas populares são LĒVO, Sinofude e Gondor Machinery.

Observação: Sempre leia as avaliações dos usuários e solicite uma demonstração, se possível. Isso o ajudará a evitar problemas mais tarde.

Custo e manutenção

Faixa de preço

Há máquinas para todos os orçamentos. Modelos para uso doméstico custo aproximado de $50 a $300. Elas são pequenas e simples de usar. As máquinas comerciais custam de $10.000 a $30.000. Elas são boas para lojas de doces ou pequenas lojas. As máquinas industriais são muito mais caras. Elas custam entre $60.000 e $280.000. Essas máquinas grandes produzem milhares de balas de goma por hora. Elas também têm recursos mais avançados.

Tipo de máquina | Faixa de preço típica (USD) |

|---|---|

Uso doméstico | $50 - $300 |

Comercial | $10.000 - $30.000 |

Industrial | $60.000 - $280.000 |

Dica: Observe os recursos que acompanham o preço. Algumas máquinas oferecem moldes extras ou controles inteligentes.

Dicas de manutenção

A limpeza de sua máquina ajuda a durar mais. Isso também ajuda a funcionar melhor. Aqui estão algumas etapas fáceis a serem seguidas:

Retire peças como moldes, aquecedores e correias para limpá-las.

Use produtos de limpeza que sejam seguros para os alimentos. Não use produtos químicos fortes.

Enxágue com água quente e use escovas macias para esfregar.

Coloque óleo de grau alimentício nas peças móveis todos os meses.

Verifique se há danos ou desgaste nos motores, aquecedores e misturadores.

Mantenha o ambiente a 20-25°C e a umidade próxima a 60%.

Adicione sensores de temperatura para verificar a máquina em tempo real.

Ensine a todos como limpar e usar a máquina com segurança.

Anote todas as limpezas e reparos em um registro.

Use bons ingredientes para ajudar a máquina a funcionar melhor.

Observação: Limpe os moldes após cada lote. Isso evita que as gomas grudem e as mantém seguras.

Solução de problemas

Às vezes, você pode ter problemas ao fazer gummies. Os funis podem entupir, as gomas podem se aglomerar ou a contagem pode estar errada. Para corrigir esses problemas, use máquinas com recursos antientupimento. Esteiras de vibração ou revestimentos de teflon ajudam a evitar entupimentos. Sensores de alta sensibilidade ajudam a contar as gomas, mesmo que elas grudem. Se a máquina estiver lenta, verifique se há peças presas ou desgastadas. Fazendo verificações regulares e treinamento da equipe ajuda a evitar a maioria dos problemas. As empresas com sistemas de monitoramento inteligente têm menos avarias e melhores gomas de mascar.

Se as gomas grudarem ou perderem o formato, altere as configurações de resfriamento ou use sprays antiaderentes.

Onde comprar

Você pode comprar máquinas em vários lugares. Para máquinas domésticas, experimente a Amazon, o Walmart ou o eBay. Esses sites têm avaliações e envio rápido. Para máquinas maiores, acesse os sites dos fabricantes, como Sinofude, Gondor Machinery ou LĒVO. Muitos vendedores oferecem treinamento, configuração e suporte. Sempre escolha um vendedor com bom atendimento após a compra.

Plataformas on-line: Amazon, Walmart, eBay

Sites do fabricante: Sinofude, Gondor Machinery,Junyu

Fornecedores especializados: Pergunte sobre garantias e suporte

Dica: Peça uma demonstração ou amostra antes de comprar uma máquina grande.

Agora você sabe como escolher a melhor máquina para você. Primeiro, pense em suas necessidades, orçamento e espaço. Faça uma lista de verificação do que é mais importante. Procure fornecedores confiáveis lendo relatórios como estes:

Fonte/Relatório | Descrição | Principais características |

|---|---|---|

candy-machines.com | Lista os principais fabricantes globais | Linhas prontas para uso, suporte e conformidade |

allpackchina.com | Diretório de fornecedores para compradores B2B | Automação, qualidade, fornecimento global |

Fornecedores de automação avançada | Controle microbiano, certificações |

Verifique os números de vendas em sua área para encontrar boas ofertas. Fique atento às novas tecnologias e mantenha sua máquina sempre limpa para obter os melhores gummies.

Perguntas frequentes

Como limpar uma máquina de balas de goma?

Primeiro, desconecte a máquina da tomada. Remova todos os moldes e bandejas. Lave cada peça com água morna e sabão. Use uma escova macia para os pontos pegajosos. Seque tudo antes de montá-lo novamente.

É possível usar receitas de doces comuns nessas máquinas?

A maioria das máquinas funciona melhor com receitas de goma. As receitas de balas comuns podem não ficar boas. Sempre verifique sua Manual da máquina para obter instruções e ingredientes aprovados.

O que você deve fazer se as gomas grudarem nos moldes?

Tente usar moldes antiaderentes ou borrife uma leve camada de óleo. Deixe as balas de goma esfriarem completamente antes de removê-las. Isso ajuda a evitar que grudem e mantém os formatos perfeitos.

Quanto tempo leva para fazer um lote de gomas?

As máquinas domésticas geralmente terminam um lote em 30 a 60 minutos. As máquinas comerciais e industriais trabalham mais rápido. Você pode consultar o manual da máquina para saber o tempo exato.

As máquinas de balas de goma são seguras para serem usadas por crianças?

A maioria das máquinas domésticas tem recursos de segurança, como exterior de toque frio e desligamento automático. Você deve sempre supervisionar as crianças durante o uso. Leia as instruções de segurança antes de começar.