Seni Pembuatan Cokelat: Dari Biji hingga Menjadi Cokelat Batangan

Bagaimana Cokelat Dibuat: Panduan Lengkap Pembuatan Cokelat Pernahkah Anda bertanya-tanya bagaimana biji kakao yang pahit berubah menjadi

Bagaimana Cokelat Dibuat: Panduan Lengkap Pembuatan Cokelat Pernahkah Anda bertanya-tanya bagaimana biji kakao yang pahit berubah menjadi

Membuat Biskuit untuk Perusahaan Lain: Panduan Lengkap Pernahkah Anda bertanya-tanya bagaimana begitu banyak merek, mulai dari kedai kopi kecil

Produksi Permen Cina: Pengantar Panduan Produsen Profesional Seiring dengan berkembangnya selera masyarakat di seluruh dunia terhadap rasa yang unik, maka

Produk Gummy China di China: Panduan Sederhana untuk Pemilik Bisnis Apakah Anda berpikir untuk memulai suplemen bergetah Anda sendiri

Panduan Lengkap untuk Menguji Kuman dan Menjaga Kualitas Tinggi dalam Pembuatan Kue Kering Pendahuluan Kue kering, biskuit, dan biskuit sangat besar

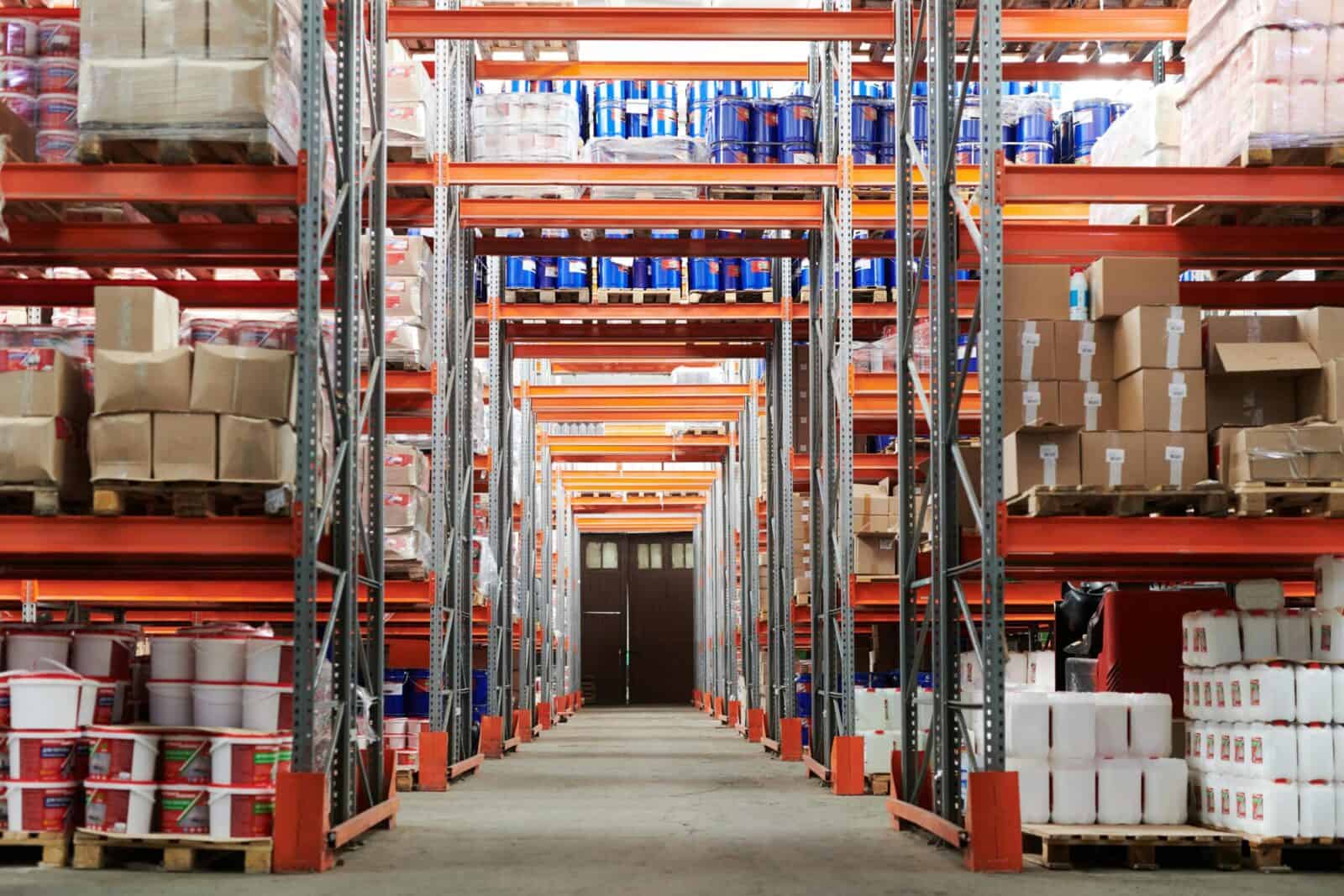

Bagaimana Perusahaan Kue Teratas Membuat Rantai Pasokan Mereka Bekerja Lebih Baik: Dari Tepung ke Toko Anda Pernahkah Anda bertanya-tanya tentang panjangnya

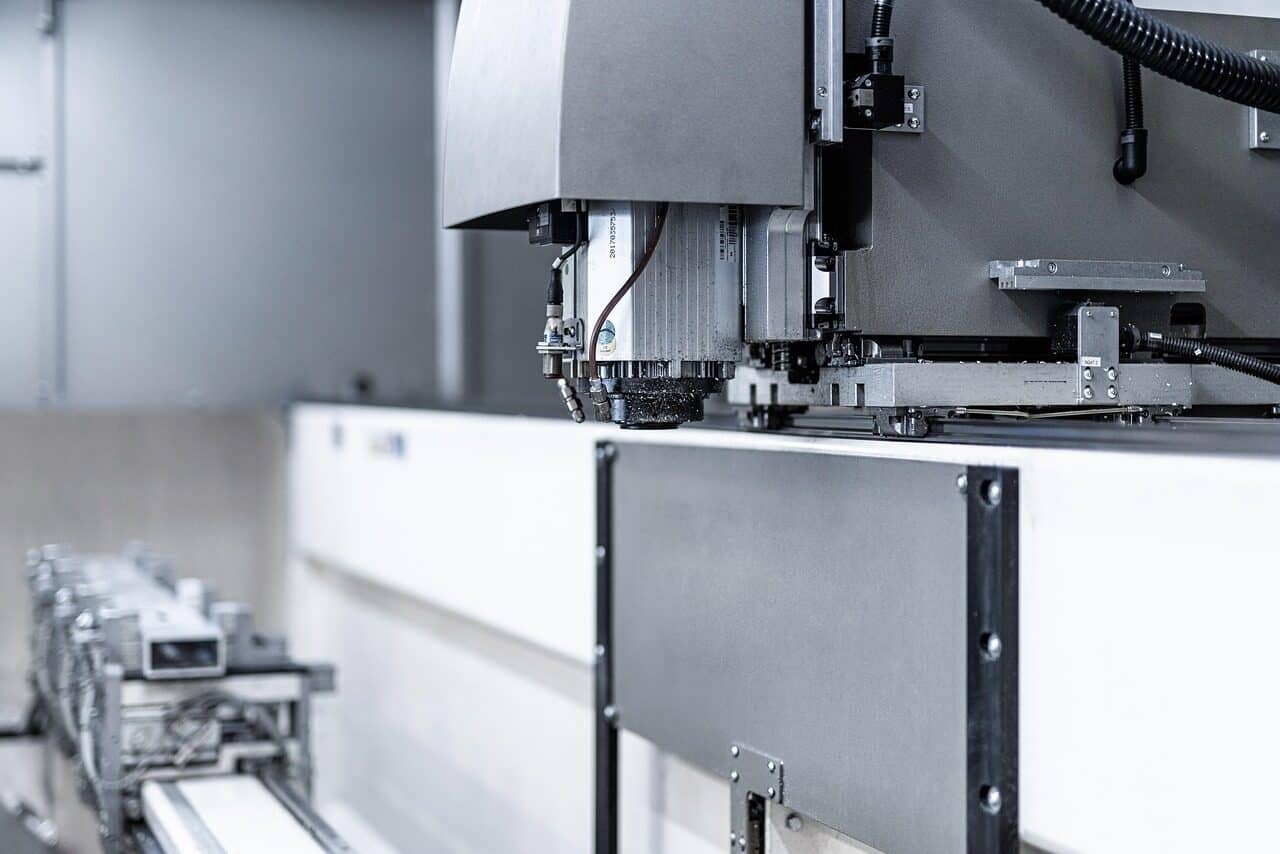

Mesin Pengemas Biskuit Canggih: Bagaimana Otomatisasi Membentuk Daya Tarik Rak Di pasar makanan panggang yang kompetitif, momen kebenaran terjadi

Tren Industri Kue Global 2025: Pertumbuhan Pasar, Preferensi Konsumen, tren pasar biskuit Memahami Lanskap yang Berubah Pasar kue global

Cara Kerja Pabrik Biskuit Modern: Panduan Sederhana untuk Membuat Kue dan Kerupuk Dari toko roti lokal hingga toko bahan makanan

Pernahkah Anda bertanya-tanya bagaimana permen bergetah favorit Anda dibuat dengan presisi dan konsistensi seperti itu? Di balik setiap camilan yang penuh warna dan kenyal

Lini Produksi Permen Efisiensi Tinggi China China telah menjadi pemimpin global dalam manufaktur maju, dan lini produksi permennya adalah

Menguasai Keterampilan: Mendalami Prinsip-prinsip Teknis Pendulangan Gula Pengantar: Di Balik Cangkang Permen Pendulangan Gula