The ingredients are gathered for baking, and molds are sprayed with oil to prevent the cake from sticking. Once filled, the molds are placed onto a conveyor belt, which inserts the molds into an automatic oven. Cakes are monitored closely so they bake evenly. They are then sprayed with a thin layer of oil to prevent cracking, and allowed to rise to its full height before being removed.

Ingredients

The ingredients of cake are the same as those used in bakery products. The most common ingredients are flour, sugar, butter and liquid leavening agents. Variations in the recipe include nuts, candied fruits, chocolate, and dried fruit. Depending on the flavor desired, some cakes can have fruit preserves or cocoa baked inside. Decorative touches include piped borders and marzipan. If you want to create an elegant and delicious cake, the most common ingredients are the same as those used in bakery products.

Flour plays the role of a structure builder in the cake. The starch in flour stiffens egg foam while the proteins in flour bind to form a strong network of coiled proteins. These ingredients also give the cake a dense texture and rich flavor. But how is a cake made in a factory constructed with these ingredients? Here’s a closer look. Here’s what you need to know.

Baking process

The baking process of a cake in a factory begins with the creation of the moulds. The cake batter is poured into the molds, which are sprayed with oil. The cake batter is then placed into an automatic oven. The temperature and humidity are carefully controlled, ensuring that the finished product bakes evenly and tastes great. Once the cake is baked, it is carefully cooled so that it does not collapse. The cake is then sprayed with water to prevent cracking, and the crust is allowed to dry. Then, cake colouring is applied to the cake.

After the ingredients are combined, the next step is to filter out impurities, such as flour, using a commercial mixer. Food processing filters ensure that the final cake mixture is uniform and free from clumps and lumps. The quality of the filter is important, as it can greatly affect the final product. The cake mixture is then beaten for 10 minutes to trap air and ensure proper rising. The final step in the baking process of a cake in a factory involves using multiple pieces of equipment.

Equipment required

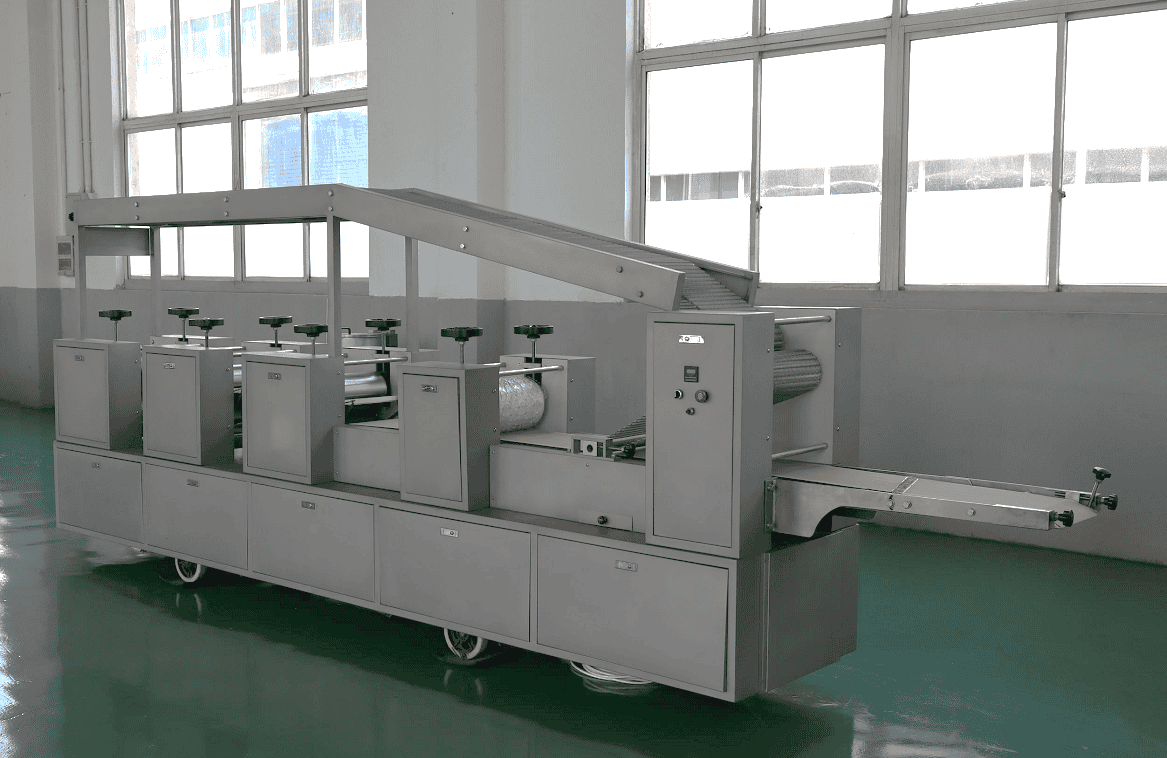

Industrial baking requires specialized equipment to produce the most delicious and healthy cakes. Commercial bakeries need various types of food processing equipment for the production of cakes. Stainless steel mesh food processing filters are among the most important equipment needed for cake production. These filters are designed to remove debris and other potential objects from the mix before it is baked. They also ensure the uniformity of the cake mixture. Here are the different types of equipment used in industrial baking.

A commercial mixer is used to mix the batter. It is beaten for ten minutes to trap air. This air, combined with a special raising agent, gives the cake its risen and expanded texture. It is then poured into a baking mold and automatically sprayed with oil to prevent it from sticking to the mold. In addition, an automatic dosing system controls the level of batter, weight, and shape of the cake.

Quality of finished product

Generally, the quality of the finished product is affected by the baking process. During baking, a semi-finished product can be crumbly, hard, and thick. The main reasons for rejecting the cake are too long of a batch, too much gluten in the flour, and too little time in the baking chamber. The baking chamber’s temperature may be set too high or too low. The baking duration should also be adequate.

Industrial baking equipment is an important part of the cake-making process. Stainless steel mesh food processing filters are among the most important pieces of equipment needed for cake production. These filters remove debris and potential objects that may be present in the cake mixture. Moreover, they help to ensure a consistent taste and texture. The quality of the finished product is the ultimate goal of all bakeries. So, how can you ensure the quality of your cake?