Gummy bears are a favorite candy for many, and consumers have come to expect a certain level of quality with every chew. Achieving consistent quality in gummy bear production is a multi-step process that involves careful ingredient selection, precise machinery operation, and rigorous quality control measures.

This article will discuss how gummy bear machines ensure that each gummy bear meets the high standards consumers expect.

1. Ingredient Quality and Consistency

The foundation of a high-quality gummy bear is the raw materials used. Gummy bear machines rely on high-quality ingredients that are consistent in their composition. This ensures that every batch of gummy bears has the same texture, flavor, and appearance.

2. Precise Dispensing of Ingredients

Gummy bear machines are equipped with systems that precisely dispense ingredients to ensure that every gummy bear has the correct proportions of gelatin, sugar, flavorings, and colorings. This precision is crucial for maintaining the uniformity of the gummy bears.

3. Automated Mixing Processes

Automated mixing processes ensure that all ingredients are thoroughly combined. Uniform mixing is vital for the consistent quality of gummy bears, as it ensures that flavors and colors are evenly distributed throughout the batch.

4. Temperature Control

Temperature plays a significant role in the gummy bear production process. Gummy bear machines have built-in temperature controls that ensure the ingredients are heated and cooled to the exact temperatures required for optimal gelling and setting.

5. Homogenization

Homogenization equipment ensures that the gummy mass is smooth and free of air bubbles, which can affect the texture and appearance of the gummy bears. This step is essential for creating a consistent product.

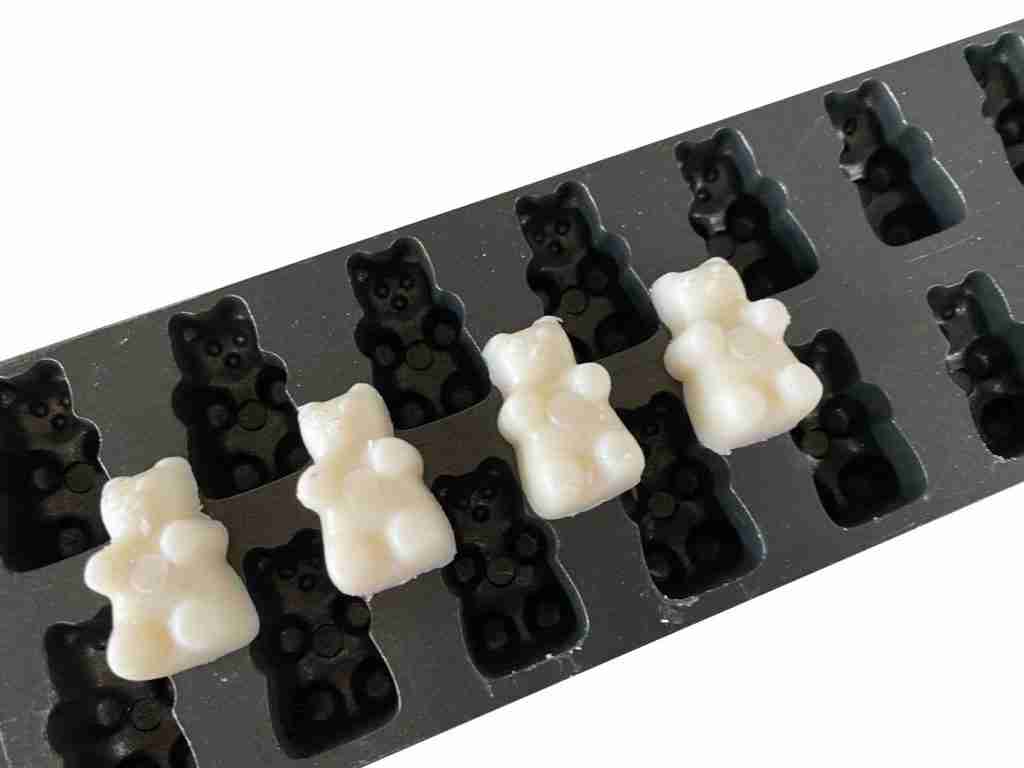

6. Mold Filling Technology

Advanced mold filling technology used in gummy bear machines guarantees that each mold is filled uniformly. This prevents underfilled or overfilled gummy bears, ensuring a consistent size and shape.

7. Cooling and Setting

The cooling and setting process is carefully controlled to ensure that each gummy bear solidifies uniformly. This is critical for maintaining the chewy texture that is characteristic of gummy bears.

8. Quality Control Sensors

Many gummy bear machines are equipped with sensors that can detect variations in size, shape, or color. These sensors help to identify and remove any gummy bears that do not meet quality standards.

9. Regular Machine Maintenance

Regular maintenance of the gummy bear machines ensures that all parts are functioning correctly and that the machine settings remain accurate. This includes calibration of dispensing systems, temperature controls, and sensors.

10. Batch Tracking

Batch tracking systems allow manufacturers to monitor and record the specific conditions and settings of each production run. This information can be used to ensure consistency across batches and to identify any potential issues.

11. Manual Quality Checks

In addition to automated systems, manual quality checks are performed by trained personnel. These checks can identify issues that automated systems might miss and provide an additional layer of quality assurance.

12. Packaging Quality

The final presentation of the gummy bears also contributes to their quality. Gummy bear machines work in conjunction with packaging equipment that ensures the gummies are sealed properly to maintain freshness and prevent contamination.

Conclusion

Ensuring the consistent quality of each gummy bear produced is a complex process that involves a combination of high-quality ingredients, precise machinery operation, and thorough quality control measures. By adhering to these standards, gummy bear manufacturers can deliver a product that is both delicious and reliable, providing consumers with the chewy goodness they love.