Introduction à la Production de bonbons

L'industrie de la confiserie connaît une croissance rapide, avec une forte demande pour une production efficace et des produits de haute qualité.

Les machines de fabrication de bonbons au caramel jouent un rôle crucial pour répondre à cette demande, en offrant un contrôle précis et un rendement constant.

L'équipement et la technologie de fabrication des bonbons sont essentiels pour produire une large gamme de bonbons, y compris les bonbons durs, les caramels et les caramels. Les entreprises fournissent des descriptions et des analyses détaillées de leurs machines afin d'aider les clients à prendre des décisions éclairées sur l'équipement le mieux adapté à leurs besoins.

Le processus de production comprend plusieurs étapes, notamment le mélange, la cuisson et le refroidissement, qui nécessitent des machines et un savoir-faire spécialisés.

Des entreprises comme Tanis et Latini proposent des solutions complètes pour la production de bonbons, y compris des machines et des équipements pour différents types de bonbons. Le choix d'une entreprise ayant une expertise éprouvée et un leadership industriel dans le domaine des équipements de fabrication de bonbons garantit aux clients des solutions de haute qualité et un service à la clientèle fiable.

Caractéristiques et avantages de la machine à fabriquer des caramels

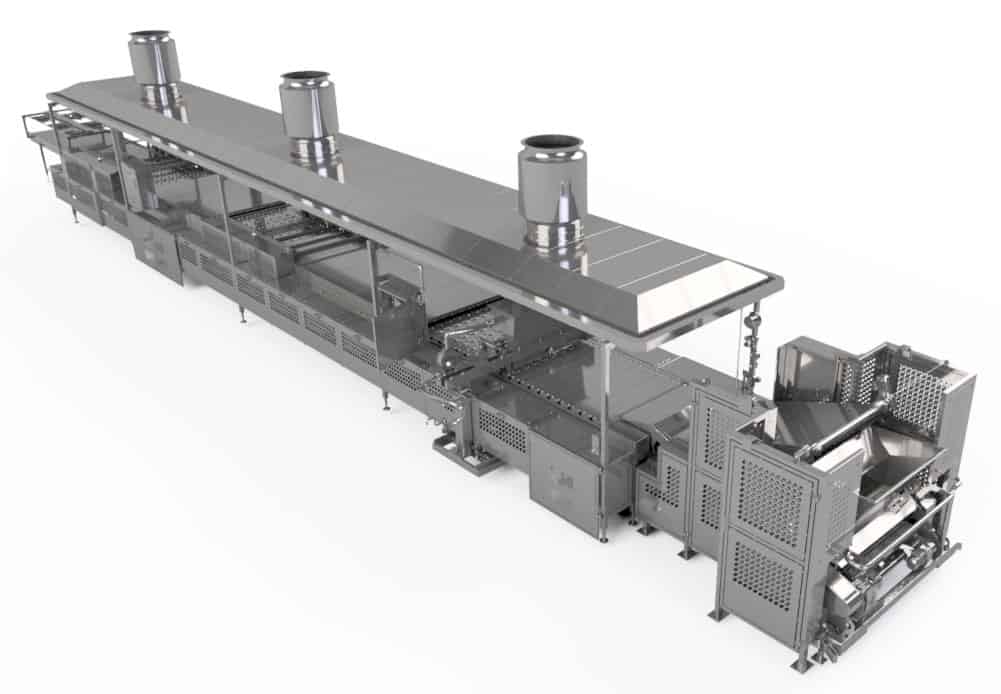

Les machines de fabrication de caramels sont conçues pour améliorer l'efficacité de l'industrie de la confiserie, avec des caractéristiques telles que l'automatisation, l'emballage et le mélange.

Ces machines offrent une capacité de production élevée, une ingénierie de précision et un rendement constant, ce qui les rend idéales pour la production de bonbons à grande échelle.

Les machines sont adaptées à la production de différentes formes et types de caramels, y compris les bonbons durs et les caramels.

Les machines à fabriquer des caramels sont faciles à utiliser et à entretenir. Elles sont dotées d'une technologie de pointe et d'une ingénierie de précision qui garantissent la qualité, la sécurité et l'efficacité.

Ils sont conçus pour améliorer l'efficacité de la production, réduire les coûts et augmenter la productivité dans l'industrie de la confiserie.

Prix de la machine et considérations relatives à l'investissement

Le prix de la machine est un facteur essentiel dans l'investissement dans une machine à fabriquer des caramels, et des facteurs tels que le modèle, la capacité de production et les caractéristiques peuvent influer considérablement sur le prix.

Les entreprises doivent tenir compte de leurs objectifs de production, de leur budget et de leurs exigences lorsqu'elles choisissent une machine appropriée.

L'investissement dans une machine à fabriquer des caramels peut être important, mais il peut aussi se traduire par des avantages à long terme, tels qu'une efficacité, une productivité et une rentabilité accrues.

Il est essentiel d'analyser les caractéristiques, les avantages et le prix de la machine pour s'assurer qu'elle répond aux besoins et au budget de l'entreprise.

En outre, les entreprises doivent prendre en compte le coût des autres machines à grignoter, de l'équipement et des machines nécessaires au processus de production.

Le processus de fabrication des bonbons durs

- Le processus de fabrication des bonbons durs comprend plusieurs étapes, notamment le mélange, la cuisson et le refroidissement.

- Ce processus nécessite des machines et des équipements spécialisés, tels que des cuiseurs, des extrudeuses et des tunnels de refroidissement. L'extrudeuse est un élément clé de ce processus, car elle façonne la masse de bonbons en différentes formes et tailles avant de poursuivre le traitement. Elle est souvent intégrée à d'autres équipements tels que la chaudière, le calibreur et le convoyeur de refroidissement afin d'améliorer l'efficacité de la production et de garantir une qualité élevée du produit.

- Le processus de production peut être affecté par divers facteurs, tels que la température, la pression et les ingrédients, qui doivent être soigneusement contrôlés pour garantir un rendement et une qualité constants.

- Les entreprises peuvent améliorer l'efficacité de leur production en adoptant des techniques de production efficaces, en investissant dans des machines de pointe et en optimisant le processus de production.

- Le processus de fabrication des bonbons durs peut être personnalisé pour produire différents types de bonbons, notamment des caramels, des caramels et des fudge.

Équipements et technologies pour la fabrication de bonbons

- L'équipement et la technologie de fabrication des bonbons jouent un rôle crucial dans la production de bonbons de haute qualité.

- L'équipement comprend des machines pour le mélange, la cuisson, le refroidissement et l'emballage, ainsi que des machines spécialisées pour des types de bonbons spécifiques.

- Des entreprises comme Tanis et Latini proposent une large gamme d'équipements et de technologies pour la fabrication de bonbons, y compris des solutions complètes pour la production de bonbons.

- Ces équipements sont conçus pour améliorer l'efficacité, la productivité et la qualité dans l'industrie de la confiserie. De nombreuses machines modernes sont également dotées de technologies d'économie d'énergie qui améliorent l'efficacité de la production et réduisent les coûts d'exploitation.

- Des technologies de pointe, telles que l'automatisation et l'ingénierie de précision, sont utilisées pour améliorer l'efficacité et la cohérence de la production.

Normes d'hygiène et de sécurité dans la fabrication du caramel

Le maintien de normes d'hygiène et de sécurité rigoureuses est essentiel dans le secteur du caramel. fabrication de bonbons L'industrie de la confiserie s'efforce de garantir à la fois la qualité des produits et la sécurité des consommateurs. À mesure que la production de bonbons augmente avec l'utilisation de machines de fabrication de caramels et d'autres machines à snacks, la complexité du maintien d'un environnement propre et sûr s'accroît. L'ingénierie de précision et l'automatisation peuvent contribuer à rationaliser le processus de production, mais des protocoles stricts doivent être mis en place à chaque étape pour prévenir la contamination et maintenir un rendement constant.

Sélection et optimisation des machines de fabrication

- Le choix de la bonne machine à fabriquer des caramels est essentiel pour une production efficace et des produits de haute qualité.

- Le degré d'automatisation d'une machine à fabriquer des caramels peut avoir un impact significatif sur l'efficacité de la production et les coûts opérationnels, un degré d'automatisation plus élevé entraînant souvent une réduction des besoins en main-d'œuvre et une amélioration de la régularité.

- Les entreprises doivent tenir compte de facteurs tels que la capacité de production, le prix de la machine et ses caractéristiques lorsqu'elles choisissent une machine appropriée.

- La machine doit être optimisée pour répondre aux objectifs et aux exigences de production de l'entreprise, et faire l'objet d'une maintenance et d'un entretien réguliers afin de garantir une production et une qualité constantes.

- Les entreprises peuvent améliorer l'efficacité de leur production en analysant les performances de la machine, en identifiant les points à améliorer et en mettant en œuvre les changements nécessaires pour optimiser le processus de production.

- En outre, les entreprises doivent tenir compte des services de vente et d'assistance proposés par le fabricant, ainsi que de la disponibilité des pièces détachées et des services de maintenance.

Conclusion et avenir du caramel candi

Le processus de production du caramel comprend plusieurs étapes cruciales pour garantir que le produit final a le goût, la texture et la qualité souhaités. Il commence par le mélange précis d'ingrédients tels que le sucre, le beurre, le lait et les arômes dans une cuve de mélange spécialisée. Ce mélange est ensuite cuit dans du caramel machines de fabrication de bonbons équipé de commandes de température précises pour obtenir la consistance parfaite du sirop sans brûler ni sous-cuire.

Une fois que le sirop a atteint le stade idéal, il est transféré dans des systèmes de refroidissement où il est rapidement refroidi pour fixer la texture du caramel. Des tunnels de refroidissement ou des convoyeurs dotés de mécanismes de refroidissement à l'air ou à l'eau sont couramment utilisés pour accélérer ce processus tout en préservant la qualité du produit. Après refroidissement, le caramel est façonné à l'aide de moules qui permettent de créer des formes et des tailles différentes, répondant ainsi aux diverses préférences des clients. Les moules personnalisés permettent aux fabricants de produire des formes uniques et d'incorporer une variété de garnitures, telles que le caramel ou le chocolat, afin de répondre aux divers besoins de leurs clients.

La ligne de production intègre l'automatisation et l'ingénierie de précision afin de maintenir un rendement constant et d'améliorer l'efficacité de la production. Tout au long du processus, des facteurs tels que la température, la pression et le temps de cuisson sont étroitement surveillés afin de créer un lot uniforme répondant à des normes de haute qualité. Enfin, les bonbons au caramel sont emballés à l'aide de machines d'emballage automatisées, prêts à être transportés et vendus.

En proposant une grande variété de formes et de garnitures, les entreprises peuvent étendre leurs capacités de production et attirer davantage de clients, en améliorant la différenciation des produits et en soutenant la croissance sur le marché concurrentiel de la confiserie.

Popularité mondiale des caramels

Les caramels sont appréciés dans le monde entier, et plus particulièrement dans les pays connus pour leurs riches traditions en matière de confiserie. Au Royaume-Uni, le caramel a une présence culturelle de longue date et est souvent associé aux sucreries traditionnelles. Les États-Unis et le Canada disposent également d'un marché solide pour les caramels, qui sont des friandises populaires lors des fêtes et des occasions spéciales. En Australie, les bonbons au caramel font partie de l'offre diversifiée de confiseries, tandis que de nombreux pays européens, dont l'Allemagne et la France, apprécient les caramels pour la richesse de leur saveur et de leur texture.

La demande mondiale de caramel continue de croître, stimulée à la fois par les préférences traditionnelles et par de nouveaux arômes innovants qui séduisent un large éventail de consommateurs. Cet attrait international fait du caramel machines de fabrication de bonbons essentielle pour les producteurs désireux de servir des marchés diversifiés et d'accroître leur production de manière efficace.

La source et l'origine du caramel

Le caramel est une confiserie traditionnelle dont les origines remontent au début du XIXe siècle et qui proviendrait d'Angleterre. Il est principalement fabriqué à partir de sucre ou de mélasse, de beurre et de lait ou de crème, qui sont cuits ensemble pour créer sa texture riche et moelleuse caractéristique et sa saveur caramélisée. Le nom "toffee" dérive probablement d'un mot dialectal signifiant "toffee" ou "toffy", qui fait référence à un type de bonbon bouilli.

Historiquement, le caramel était une friandise populaire dans les familles ouvrières britanniques et, au fil du temps, son attrait s'est étendu à l'échelle internationale, devenant une confiserie appréciée dans de nombreux pays. La simplicité de ses ingrédients, combinée à un processus de cuisson habile, fait du caramel une confiserie classique qui peut être adaptée avec différentes saveurs et inclusions, telles que des noix ou du chocolat.

Aujourd'hui, le caramel machines de fabrication de bonbons sont conçus pour reproduire les méthodes traditionnelles de cuisson et de mélange à l'échelle industrielle, garantissant ainsi une qualité et une texture constantes tout en répondant aux exigences de production élevées dans le monde entier. Les ingrédients d'origine - sucre, beurre et crème - restent au cœur de la production de caramel, ce qui souligne l'importance de matériaux de qualité en contact avec les aliments et d'un contrôle précis de la température au cours du processus de fabrication.