Le meilleur Machine à bonbons gélifiés Solutions pour une production efficace

Introduction à l'industrie

L'industrie de la confiserie offre des possibilités infinies en matière de production de bonbons gélifiés, avec différentes formes, saveurs et tailles de bonbons gélifiés et de friandises gélifiées disponibles. Les entreprises peuvent choisir parmi une large gamme de machine à bonbons gélifiés des solutions adaptées à leurs besoins.

Il existe de nombreux types de machines de fabrication de bonbons gélifiés et de gommes à mâcher dans l'industrie, qui répondent à des besoins de production variés. L'un des principaux types de machines utilisées dans la production de bonbons gélifiés est la machine de dépôt, qui joue un rôle essentiel dans la formation et la mise en forme efficaces des bonbons gélifiés.

Les oursons gélifiés, les gommes vitaminées et d'autres produits innovants sont très demandés, ce qui fait des machines à fabriquer des bonbons gélifiés un élément essentiel du processus de fabrication. Avec l'équipement adéquat, les entreprises peuvent trouver la solution parfaite pour produire n'importe quel type de bonbon gélifié.

Avec le bon équipement de production de bonbons gélifiés, les entreprises peuvent augmenter leur production et créer des bonbons gélifiés de haute qualité qui répondent aux besoins des clients.

Le secteur est en constante évolution, avec l'apparition de nouvelles technologies et de nouveaux équipements destinés à améliorer l'efficacité et la productivité de la fabrication des chewing-gums.

Que vous soyez intéressé par des petites ou moyennes séries, il existe une machine de fabrication de bonbons gélifiés adaptée aux besoins de votre entreprise.

Équipements et machines

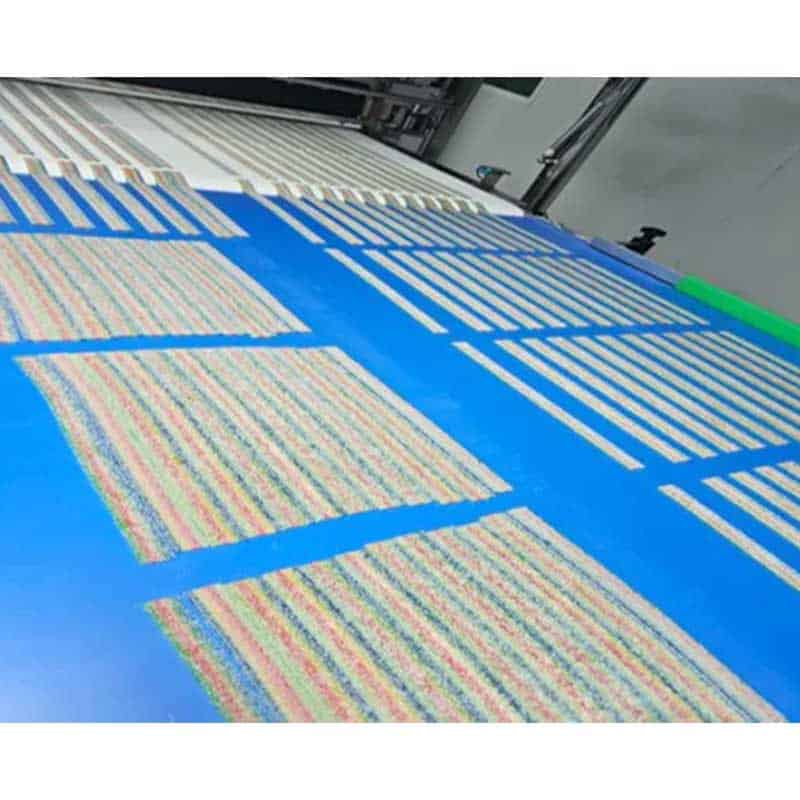

Fabrication de gommes Les machines sont conçues pour produire des bonbons gélifiés en différentes formes, tailles et saveurs, avec des options de personnalisation permettant de créer des gommes de la forme et de la taille souhaitées.

Les équipements de confiserie, tels que les cuves de stockage, les cuves de dissolution du sucre, les équipements de fusion de la gélatine et les moules à gommes, sont des composants essentiels d'une ligne de production de gommes. Le réservoir de stockage joue un rôle crucial dans la conservation et le stockage d'ingrédients tels que les sucres et autres matières premières avant leur transformation. Une conception et une capacité adéquates du réservoir de stockage sont importantes pour assurer un flux de production efficace et maintenir une qualité de produit constante.

Les machines innovantes de fabrication de gommes offrent des caractéristiques avancées, telles que le dosage automatique et les tunnels de refroidissement, afin d'améliorer la capacité de production et l'efficacité.

Lorsque vous choisissez un équipement, tenez compte de facteurs tels que les spécifications de production, la vitesse de la machine et les exigences en matière de nettoyage afin de garantir un processus de fabrication sans heurts. Nous vous encourageons à nous faire part de vos spécifications de production afin que nous puissions vous recommander l'équipement de fabrication de bonbons gélifiés le mieux adapté à vos besoins.

Une machine à fabriquer des bonbons gélifiés fiable peut aider les entreprises à gagner du temps et de l'argent tout en produisant des bonbons gélifiés de haute qualité.

Fabrication de produits

- La production de chewing-gums comporte plusieurs étapes, du mélange à la cuisson, en passant par le moulage et le séchage, qui nécessitent des équipements et des machines spécialisés.

- Les machines de fabrication de gommes peuvent produire une large gamme de produits, notamment des oursons en gomme, des vers en gomme et d'autres formes et tailles amusantes.

- Pour créer des produits innovants, les entreprises peuvent expérimenter différentes recettes, saveurs et ingrédients, tels que les vitamines et les minéraux.

- Le processus de fabrication peut être optimisé grâce à l'équipement et aux techniques appropriés, ce qui garantit une qualité et une texture constantes dans chaque lot.

- Avec la bonne machine à fabriquer des bonbons gélifiés, les entreprises peuvent produire des bonbons gélifiés à la fois amusants et sains.

- Les machines avancées de fabrication de gommes sont conçues pour répondre aux besoins des petites entreprises et des fabricants à grande échelle.

Variations et personnalisation des produits

Au cœur de toute ligne de production de bonbons gélifiés réussie se trouve la capacité à créer un large éventail de variations de produits et d'options de personnalisation. C'est là que les machines de fabrication de bonbons à la gomme brillent vraiment, en offrant des possibilités infinies de produits innovants qui peuvent répondre aux diverses préférences des consommateurs. Qu'il s'agisse d'oursons gélifiés, de bonbons vitaminés ou d'autres types de bonbons gélifiés, le bon équipement de production de bonbons gélifiés peut faire toute la différence.

Grâce à des équipements de confiserie de pointe, les fabricants peuvent produire des bonbons gélifiés de formes, de tailles et de saveurs variées, qui conviennent à des groupes d'âge et à des intérêts différents. Par exemple, les moules à bonbons peuvent être conçus pour créer des formes amusantes et attrayantes que les enfants adorent, tout en offrant des options saines telles que des bonbons infusés de vitamines pour les consommateurs soucieux de leur santé.

Le processus de fabrication des bonbons gélifiés est hautement personnalisable, ce qui permet aux entreprises d'expérimenter de nouvelles recettes, saveurs et textures pour garder une longueur d'avance sur la concurrence. Le dosage des ingrédients permet une personnalisation précise des arômes, des couleurs et du contenu nutritionnel, ce qui garantit que chaque lot répond à des exigences spécifiques. En investissant dans une machine de fabrication de bonbons gélifiés de haute qualité, les entreprises peuvent améliorer leurs capacités de production, accroître leur efficacité et réduire leurs coûts. Elles peuvent ainsi proposer une large gamme de produits à base de gommes à des prix compétitifs, ce qui les rend plus attrayantes pour les clients.

En termes de spécifications de production, les machines de fabrication de gommes peuvent traiter des séries de production moyennes à grandes, produisant des milliers de gommes par heure. Le processus de fabrication comprend plusieurs étapes, notamment le mélange, le chauffage et l'agitation, qui sont toutes automatisées pour garantir la cohérence et la qualité. Avec l'équipement adéquat, les entreprises peuvent produire des gommes de différentes tailles, des petits oursons aux formes plus grandes, et dans une variété d'arômes pour répondre aux différents goûts.

L'industrie de la confiserie est en constante évolution, et la fabrication de bonbons gélifiés ne fait pas exception. En choisissant le bon équipement de production de bonbons gélifiés et les bonnes options de personnalisation, les entreprises peuvent se donner les moyens de créer des produits innovants qui répondent aux besoins changeants des consommateurs. Que vous cherchiez à produire des bonbons gélifiés pour les enfants ou des en-cas sains pour les adultes, la bonne machine peut vous aider à atteindre vos objectifs.

Pour en savoir plus sur les machines de fabrication de bonbons gélifiés et les options de personnalisation, contactez nos experts dès aujourd'hui. Nous pouvons vous guider dans le processus de sélection de l'équipement idéal pour les besoins de votre entreprise et vous fournir un devis pour commencer. Avec notre aide, vous pouvez rejoindre le monde de la fabrication de chewing-gums et commencer à produire des chewing-gums de haute qualité qui raviront vos clients. Explorez notre gamme de machines de fabrication de chewing-gums et découvrez les possibilités infinies qui s'offrent à votre entreprise.

Contrôle de la qualité et conformité

Au cœur de toute opération de production de bonbons gélifiés réussie se trouve un cadre solide de contrôle de la qualité et de la conformité. Ce cadre est essentiel pour garantir que tous les bonbons gélifiés, y compris les oursons gélifiés, les gommes vitaminées et d'autres produits innovants, répondent aux normes les plus strictes en matière de qualité, de sécurité et de conformité aux réglementations. Le contrôle de la qualité dans la fabrication des bonbons gélifiés implique plusieurs étapes clés, depuis l'approvisionnement en matières premières jusqu'à l'emballage final des produits gélifiés.

Pour les fabricants d'équipements de production de bonbons à la gomme, il est essentiel de se conformer aux normes internationales de qualité telles que la norme ISO 9001 et aux normes de sécurité alimentaire telles que la norme HACCP (analyse des risques et maîtrise des points critiques). Ces normes garantissent que les machines de fabrication de gommes et l'ensemble de la chaîne de production sont conçus et exploités de manière à prévenir la contamination et à garantir la qualité constante des gommes produites.

Dans le contexte de la fabrication des bonbons gélifiés, le contrôle de la qualité implique également l'inspection et l'entretien réguliers des moules à bonbons gélifiés, des réservoirs de stockage et d'autres équipements de confiserie afin d'éviter l'usure qui pourrait affecter la qualité des bonbons gélifiés. En outre, le processus de fabrication doit être soigneusement contrôlé, notamment en ce qui concerne la température, la durée du mélange et la vitesse d'agitation, afin d'obtenir la meilleure qualité possible. une texture et une consistance parfaites dans chaque lot de gommes.

Pour les entreprises qui souhaitent améliorer leur production de bonbons à la gomme, il est stratégique d'investir dans des machines de fabrication de bonbons à la gomme de pointe, conçues dans un souci de contrôle de la qualité et de conformité. Ces machines sont capables de produire des bonbons gélifiés de différentes formes et tailles, des petits oursons gélifiés aux formes plus grandes et plus complexes, tout en maintenant des vitesses de production et une efficacité élevées.

Lors de la sélection d'un fournisseur d'équipements de production de bonbons gélifiés, il est essentiel de rechercher des entreprises qui accordent la priorité au contrôle de la qualité et à la conformité. Il s'agit notamment de vérifier les certifications, d'examiner les processus de contrôle de la qualité et d'évaluer l'expérience de l'entreprise dans l'industrie de la confiserie. En s'associant à un fournisseur réputé, les entreprises peuvent s'assurer que leurs opérations de fabrication de bonbons gélifiés sont non seulement efficaces et rentables, mais qu'elles produisent également des bonbons gélifiés de haute qualité qui répondent aux attentes des clients, voire les dépassent.

En conclusion, le contrôle de la qualité et la conformité sont des éléments fondamentaux d'une production réussie de bonbons gélifiés. En comprenant l'importance de ces aspects et en investissant dans les machines et les processus de fabrication de bonbons gélifiés appropriés, les entreprises peuvent produire une large gamme de bonbons gélifiés, y compris des oursons gélifiés, des bonbons vitaminés et d'autres produits amusants et innovants, qui sont à la fois agréables et sûrs pour les consommateurs de tous âges. Que vous souhaitiez produire des bonbons gélifiés à petite échelle ou en moyenne série, le fait de donner la priorité au contrôle de la qualité et à la conformité permettra à votre entreprise d'atteindre ses objectifs et de prospérer dans le secteur concurrentiel de la confiserie.

Optimisation des processus de production

- Pour optimiser le processus de production, les entreprises peuvent se concentrer sur l'amélioration de l'efficacité, la réduction des déchets et l'amélioration de la qualité des produits.

- Les équipements de production de gommes peuvent être personnalisés pour répondre à des besoins de production spécifiques, tels que la production de moyennes séries ou la fabrication à grande échelle.

- L'utilisation de technologies avancées, telles que l'automatisation, la robotique et le contrôle par automate programmable, peut contribuer à rationaliser le processus de fabrication et à réduire les coûts de main-d'œuvre.

- L'entretien et le nettoyage réguliers des équipements sont essentiels pour garantir le bon déroulement du processus de production et éviter les temps d'arrêt.

- En optimisant le processus de production, les entreprises peuvent accroître leur productivité, réduire leurs coûts et améliorer la satisfaction de leurs clients.

Choisir le bon fournisseur de solutions

- Lors de la sélection d'une machine à fabriquer des bonbons gélifiés ou d'un fournisseur d'équipement, il convient de tenir compte de facteurs tels que l'expérience, l'expertise et l'assistance à la clientèle.

- Recherchez un fournisseur qui propose une large gamme d'équipements et de machines, ainsi que des solutions personnalisées pour répondre à des besoins de production spécifiques.

- Un fournisseur fiable doit offrir des conseils et une assistance tout au long du processus de fabrication, de l'installation à la maintenance et à la réparation.

- Tenez compte de la réputation du fournisseur, des avis des clients et des témoignages pour vous assurer que vous travaillez avec un partenaire de confiance.

- En choisissant le bon fournisseur de solutions, les entreprises peuvent augmenter leur production de chewing-gums, améliorer leur efficacité et accroître la satisfaction de leurs clients.