Introducción a la fabricación de caramelos

- La producción de caramelos implica el uso de máquinas y equipos avanzados de fabricación de caramelos para producir productos de confitería de alta calidad.

- El proceso de fabricación de caramelos requiere una cuidadosa consideración de los ingredientes, las fases de cocción y el envasado para garantizar los mejores resultados.

- Los fabricantes de confitería pueden beneficiarse de la inversión en sistemas eficientes de producción de caramelos que den prioridad a la calidad y la escalabilidad.

La máquina de fabricación de caramelos es un elemento esencial para la producción profesional de caramelos, ya que ofrece las características clave y la fiabilidad necesarias en el proceso.

- Comprender los fundamentos de la fabricación de caramelos es crucial para producir una amplia gama de productos de caramelo, incluidos caramelos duros y caramelos blandos.

- La industria del dulce depende de tecnologías y técnicas innovadoras para mantenerse por delante de la competencia y satisfacer las demandas de los clientes.

Máquinas para hacer caramelos

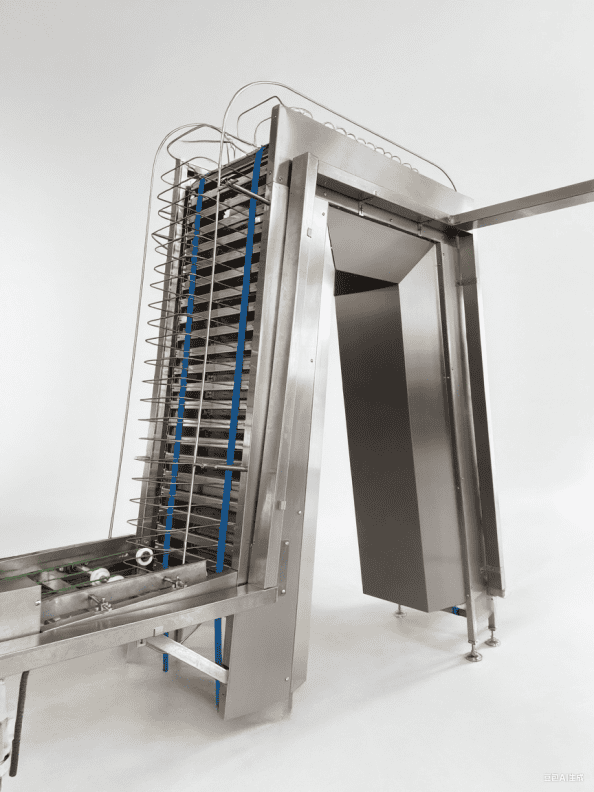

- Las máquinas de fabricación de caramelos están diseñadas para agilizar el proceso de producción, desde la mezcla y la cocción hasta el moldeado y el envasado.

- Las máquinas avanzadas pueden manejar varios tipos de producción de caramelos, incluidos los caramelos duros, toffees y chicles.

- Invertir en la maquinaria adecuada para fabricar caramelos puede ayudar a los fabricantes a aumentar la eficacia, reducir los costes y mejorar la calidad del producto.

- Los proveedores de máquinas de caramelos ofrecen una gama de máquinas, desde las de pequeña escala hasta las de gran escala, para adaptarse a las diferentes necesidades empresariales y niveles de producción. Es esencial contar con el equipo adecuado para garantizar la fluidez de las operaciones de fabricación de caramelos.

- El uso de acero inoxidable en las máquinas de fabricación de caramelos garantiza su durabilidad y facilidad de limpieza, por lo que es una opción muy popular entre los fabricantes.

Productos de confitería y fabricación

- Los productos de confitería se presentan en una amplia gama de formas, tamaños y sabores, y requieren equipos y técnicas de producción especializados.

- Fabricación de caramelos implica varias etapas, como la mezcla, la cocción y el moldeado, que pueden automatizarse con máquinas avanzadas.

- Los fabricantes de confitería pueden producir una gran variedad de productos, como caramelos duros, caramelos blandos y gomas de mascar, utilizando distintos ingredientes y recetas.

- El uso de azúcar, jarabe de maíz y otros ingredientes es crucial en la producción de caramelos, y los fabricantes deben controlar cuidadosamente el proceso de cocción para conseguir la textura y el sabor deseados.

- La producción de caramelos también implica el uso de inclusiones, como frutos secos, frutas y colores, para crear productos únicos y atractivos.

- Durante el proceso de estirado, el caramelo se airea y su color se vuelve más claro y opaco, realzando su atractivo visual.

Equipos y suministros para máquinas de caramelos

- Los equipos y suministros de las máquinas de caramelos son esenciales para mantener una producción eficiente y garantizar productos de alta calidad.

- Los fabricantes pueden elegir entre una gama de equipos, como mezcladoras, cocedoras y formadoras, que se adaptan a sus necesidades específicas.

- Los suministros para la fabricación de caramelos, como aromatizantes, colorantes y materiales de envasado, también son cruciales para producir una amplia gama de productos de confitería.

Disponer de equipos y suministros listos para su uso inmediato es crucial para una producción eficiente de caramelos.

- El uso de equipos y suministros de alta calidad puede ayudar a los fabricantes a garantizar resultados uniformes y satisfacer las expectativas de los clientes.

- Invertir en los equipos y suministros adecuados también puede ayudar a reducir los residuos, mejorar la eficiencia y aumentar la rentabilidad.

Fabricación de caramelos y técnicas

- La fabricación de caramelos implica diversas técnicas, como tirar, estirar y dar forma, para crear productos únicos y atractivos.

- El tirón aumenta el volumen del caramelo, mejorando su textura y aspecto.

- Los fabricantes pueden utilizar distintos ingredientes y recetas para producir una amplia gama de caramelos, desde caramelos duros a caramelos blandos y chicles.

- El uso de técnicas de moldeado y deposición de almidón puede ayudar a los fabricantes a crear formas y diseños complejos.

- La fabricación de caramelos también implica un cuidadoso control de la temperatura, la humedad y el tiempo de cocción para conseguir la textura y el sabor deseados.

- Ciertas máquinas son adecuadas para extraer tamaños de lote específicos, como 5 kg, en la fabricación artesanal de caramelos.

- Experimentar con nuevos ingredientes y técnicas puede ayudar a los fabricantes a adelantarse a la competencia y crear productos innovadores.

Ampliación de la fabricación de caramelos

- La ampliación de la fabricación de caramelos exige un examen minucioso del equipo, los ingredientes y los procesos de producción.

- Los fabricantes pueden invertir en máquinas y equipos más grandes para aumentar la capacidad de producción y satisfacer la creciente demanda.

- El uso de sistemas automatizados y procesos de producción eficientes puede ayudar a los fabricantes a reducir costes y mejorar la calidad de los productos.

- Aumentar la producción también requiere una planificación y gestión cuidadosas para garantizar resultados coherentes y cumplir las expectativas de los clientes.

- Invertir en la formación y el desarrollo de los empleados también puede ayudar a los fabricantes a mejorar la eficiencia y la productividad.

Producción de caramelos duros y blandos

- La producción de caramelos duros implica el uso de equipos y técnicas especializadas para crear una textura dura y vidriosa.

- La producción de caramelos blandos, en cambio, requiere un cuidadoso control de los ingredientes y los procesos de cocción para conseguir una textura masticable o blanda.

- Los fabricantes pueden utilizar distintos ingredientes, como azúcar, jarabe de maíz y gelatina, para producir una amplia gama de caramelos duros y blandos.

- El uso de colores, sabores e inclusiones puede ayudar a los fabricantes a crear productos únicos y atractivos.

- La producción de caramelos duros y blandos también implica una cuidadosa consideración del envasado y el almacenamiento para garantizar la frescura y la calidad.

Moldeo y depósito de almidón

El moldeado y el depósito de almidón son procesos esenciales en la producción moderna de caramelos, especialmente para los fabricantes de confitería que desean producir caramelos duros, gomas y otros productos de confitería a base de almidón de alta calidad. En la fase de moldeado del almidón, las máquinas de fabricación de caramelos utilizan bandejas de almidón para dar formas y tamaños precisos, garantizando que cada lote de caramelos cumpla las normas más estrictas de aspecto y textura. El depósito, por su parte, consiste en transferir la mezcla de caramelo cocido a moldes o bandejas de almidón, lo que permite una producción de lotes uniforme y una flexibilidad creativa en el diseño de los caramelos. Los fabricantes pueden elegir entre una gama de máquinas diseñadas para diferentes escalas de producción, desde pequeños lotes artesanales hasta fabricación industrial a gran escala. Estas máquinas suelen estar fabricadas en acero inoxidable, lo que no sólo garantiza su durabilidad, sino que también cumple estrictos requisitos de higiene. Al integrar los sistemas de moldeado y depósito de almidón en sus líneas de producción, los fabricantes de dulces pueden aumentar la eficacia, reducir el trabajo manual y producir de forma fiable caramelos que deleitan a los clientes por su calidad y uniformidad.

Automatización y tecnología inteligente en Fabricación de dulces

La integración de la automatización y la tecnología inteligente ha revolucionado la fabricación de caramelos, permitiendo a los fabricantes de confitería alcanzar nuevos niveles de eficiencia y consistencia del producto. Las máquinas automatizadas de fabricación de caramelos agilizan todas las fases de producción, desde la mezcla de ingredientes y la cocción hasta el moldeado y el envasado, lo que agiliza los plazos de entrega y reduce los costes de mano de obra. La tecnología inteligente, como sensores avanzados y sistemas de supervisión en tiempo real, puede integrarse en los equipos de producción para controlar con precisión variables como la temperatura, la concentración de azúcar y el tiempo de cocción. Esto garantiza que cada lote de caramelos se produzca según las especificaciones exactas, minimizando los residuos y maximizando la calidad. Las máquinas de envasado automático mejoran aún más la productividad envolviendo los caramelos de forma rápida e higiénica, reduciendo el riesgo de contaminación y garantizando un producto final pulido. Al adoptar la automatización y la tecnología inteligente, los fabricantes de caramelos pueden responder rápidamente a las demandas del mercado, mantener altos niveles de calidad y ofrecer a sus clientes productos de confitería siempre excelentes.

Normas de higiene y saneamiento

Para garantizar la seguridad y calidad de los productos de confitería, es fundamental cumplir rigurosas normas de higiene y saneamiento. Los fabricantes de productos de confitería deben asegurarse de que todas las máquinas y equipos de fabricación de caramelos estén diseñados para facilitar su limpieza y construidos con materiales como el acero inoxidable, que resiste la corrosión y favorece un saneamiento exhaustivo. Los programas de limpieza periódica y las rutinas de mantenimiento son esenciales para evitar la acumulación de residuos de azúcar y otros contaminantes que podrían comprometer la calidad del producto. El personal debe recibir formación sobre las mejores prácticas de higiene, incluido el uso de ropa protectora y la manipulación adecuada de los lotes de caramelos, para evitar la contaminación cruzada. Al dar prioridad a la higiene en todas las fases de la producción, los fabricantes no sólo cumplen la normativa del sector, sino que también generan confianza entre los clientes al ofrecer siempre caramelos seguros y de alta calidad. Invertir en equipos bien diseñados y fáciles de limpiar es un paso clave para garantizar la integridad de cada lote producido.

Soluciones de envasado para productos de confitería

El envasado desempeña un papel fundamental en el éxito de los productos de confitería, ya que sirve tanto para proteger los caramelos como para atraer a los clientes. Los fabricantes de golosinas disponen de una amplia gama de opciones de envasado entre las que elegir, como envoltorios individuales, bolsas con cierre, cajas decorativas y contenedores resistentes, cada uno de ellos diseñado para adaptarse a diferentes tipos de caramelos y preferencias de mercado. Las modernas máquinas de envasado pueden automatizar el proceso, garantizando que los caramelos se envasen de forma rápida, eficaz y con una manipulación mínima, lo que ayuda a mantener la calidad y la higiene del producto. Las soluciones de envasado personalizables permiten a los fabricantes mejorar su identidad de marca mediante diseños, etiquetas y acabados exclusivos. Al seleccionar el envase, es importante tener en cuenta factores como la durabilidad, la sostenibilidad y la capacidad de conservar la frescura. Características como las barreras contra la humedad y los precintos a prueba de manipulaciones pueden garantizar aún más la calidad del producto hasta que llega al cliente. Al invertir en soluciones de envasado innovadoras y bien diseñadas, los fabricantes de productos de confitería pueden elevar el nivel de sus productos, mejorar la satisfacción del cliente y reforzar su posición en un mercado competitivo.

Eficiencia energética y sostenibilidad en la producción de caramelos

A medida que la preocupación por el medio ambiente va cobrando importancia, la eficiencia energética y la sostenibilidad se han convertido en prioridades clave de la industria europea. fabricación de caramelos industria. Los fabricantes de confitería pueden tener un impacto significativo adoptando máquinas y equipos de fabricación de caramelos energéticamente eficientes, como los que incorporan motores de bajo consumo y sistemas avanzados de recuperación de calor. La integración de prácticas sostenibles -como la reducción del consumo de agua, la minimización de los residuos de producción y la elección de materiales de envasado ecológicos- puede reducir aún más la huella medioambiental de la producción de caramelos. Estos esfuerzos no sólo ayudan a los fabricantes a reducir los costes operativos, sino que también atraen a clientes concienciados con el medio ambiente y cumplen con la normativa industrial en constante evolución. Al dar prioridad a la eficiencia energética y a la sostenibilidad, los fabricantes demuestran su compromiso con una producción responsable, al tiempo que garantizan la viabilidad del negocio a largo plazo. Adoptar estas prácticas permite a los fabricantes de confitería producir caramelos de alta calidad de una forma que beneficia tanto a su negocio como al planeta.

Moldeado y depósito de almidón

- El moldeado y la deposición de almidón son técnicas utilizadas para crear formas y diseños complejos en la producción de caramelos.

- Los fabricantes pueden utilizar máquinas de moldeado de almidón para crear formas y diseños precisos, mientras que el depositado implica el uso de una máquina para depositar la mezcla de caramelo en los moldes.

- Estas técnicas requieren un cuidadoso control de los ingredientes, la temperatura y la humedad para conseguir la textura y la forma deseadas.

- El moldeado y la deposición de almidón pueden utilizarse para producir una amplia gama de productos de confitería, como caramelos duros, caramelos blandos y gomas de mascar.

- El uso de estas técnicas puede ayudar a los fabricantes a crear productos únicos e innovadores que destaquen en el mercado.

Control y garantía de calidad

- El control y la garantía de calidad son cruciales en la fabricación de caramelos para asegurar resultados uniformes y satisfacer las expectativas de los clientes.

- Los fabricantes pueden aplicar medidas de control de calidad, como pruebas e inspecciones, para garantizar que los productos cumplen las normas de calidad y seguridad.

- El uso de ingredientes y equipos de alta calidad también puede ayudar a los fabricantes a garantizar resultados uniformes.

- La garantía de calidad implica una cuidadosa planificación y gestión para asegurar que los productos se fabrican de acuerdo con las normas más exigentes.

- Los fabricantes también pueden invertir en la formación y el desarrollo de sus empleados para mejorar la calidad y la eficiencia.

Mantenimiento y resolución de problemas

- El mantenimiento periódico es esencial para garantizar el buen funcionamiento de las máquinas y equipos de fabricación de caramelos.

- Los fabricantes pueden realizar tareas rutinarias de mantenimiento, como limpieza y lubricación, para evitar averías y reducir el tiempo de inactividad.

- La resolución de problemas implica identificar y resolver los problemas rápidamente para minimizar las interrupciones de la producción.

- Los fabricantes pueden invertir en piezas de repuesto y sistemas de reserva para garantizar que la producción pueda continuar sin interrupciones.

- El mantenimiento periódico y la resolución de problemas pueden ayudar a los fabricantes a mejorar la eficiencia, reducir los costes y prolongar la vida útil de los equipos.

Futuro de la fabricación de caramelos y tendencias

- El futuro de la fabricación de caramelos pasa por el uso de tecnologías y técnicas innovadoras para crear productos únicos y atractivos.

- Los fabricantes pueden invertir en investigación y desarrollo para adelantarse a la competencia y satisfacer las cambiantes demandas de los clientes.

- El uso de ingredientes y envases sostenibles y ecológicos puede ayudar a los fabricantes a atraer a consumidores concienciados con el medio ambiente.

- Se prevé que la industria del dulce siga creciendo, con la aparición de nuevas tendencias y tecnologías para satisfacer las cambiantes preferencias de los consumidores.

- Los fabricantes pueden adelantarse a la competencia invirtiendo en la formación y el desarrollo de sus empleados y adoptando nuevas tecnologías y técnicas para mejorar la eficiencia y la productividad.