Guía del ingeniero para el termosellado en el envasado de caramelos: Un análisis técnico

El termosellado es algo más que aplicar calor y presión a las películas de plástico. En la producción de dulces, es un proceso de precisión controlada basada en la física de los polímeros, la termodinámica y la ciencia de los materiales. El objetivo es crear juntas herméticas de fusión molecular que protegen la frescura, garantizan la seguridad y mantienen el atractivo del producto.

Esta guía proporciona una marco técnico profundo para ingenieros de envasadoy profesionales de la calidad. Desglosamos el termosellado de caramelos en su principios fundamentalespermitiendo selección de materiales, optimización de procesos y resolución de problemas en las líneas de producción.

De la adhesión a la fusión molecular en el envasado de caramelos

El termosellado en las envolturas de caramelos no es una adhesión superficial. Se trata de interdifusión de cadenas poliméricas a nivel molecular. La comprensión de este proceso transforma el sellado de un arte de "caja negra" en ciencias de la ingeniería predecibles.

De qué trata esta guía:

-

La física: transferencia de calor y principios termodinámicos.

-

La ciencia de los materiales: propiedades de los polímeros que permiten el sellado térmico.

-

La trinidad del proceso: temperatura, presión y tiempo de permanencia.

-

Comparación de tecnologías: barra caliente, inducción, ultrasonidos y sellado por aire caliente.

-

Resolución de problemas y defectos análisis de las líneas de caramelos.

La física fundamental

Transferencia de calor en el envasado de caramelos

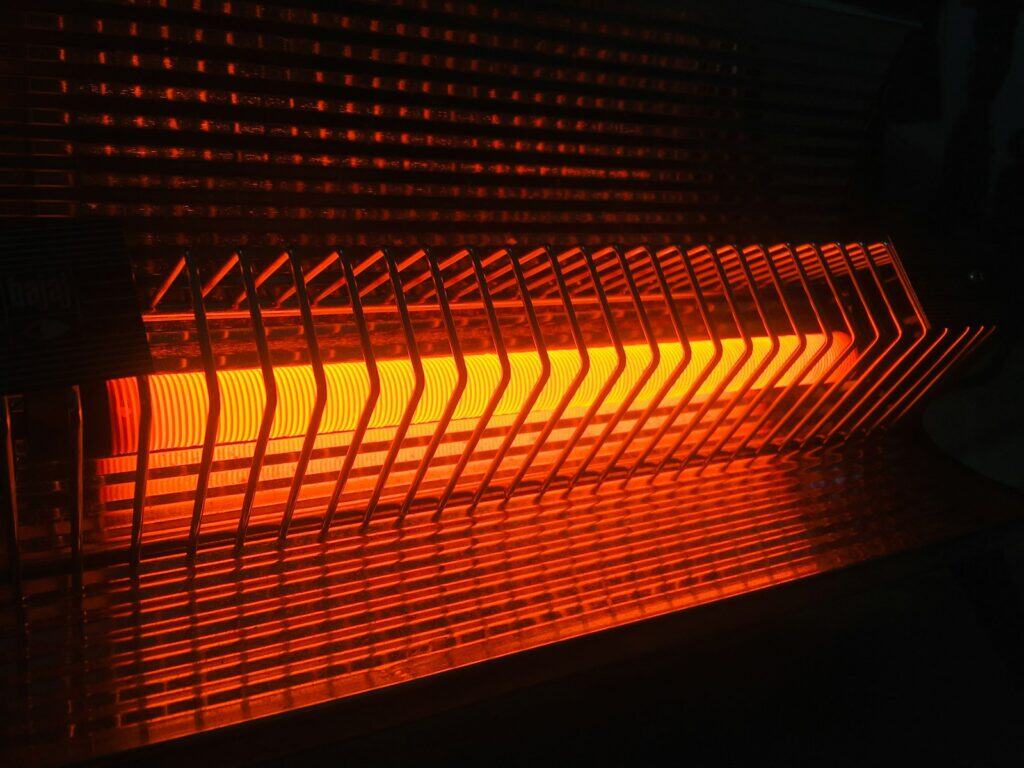

La conducción es el modo de transferencia de energía más común en el sellado térmico de caramelos. Mordazas o barras calentadas capas de película de contacto directamente, transfiriendo energía al sellador.

Otros métodos son:

-

Sellado por aire calienteTransferencia de calor por convección mediante chorros de aire caliente.

-

Induccióncampos electromagnéticos capas de láminas conductoras del calor dentro de los envoltorios de caramelos.

-

Sellado por ultrasonidosLas vibraciones de alta frecuencia generan calor localizado por fricción.

La conducción sigue siendo la norma del sector para flexible envasado de caramelos por su fiabilidad y sencillez.

Principios termodinámicos

Dos temperaturas rigen el comportamiento de los polímeros:

-

Temperatura de transición vítrea (Tg): Punto en el que las cadenas poliméricas amorfas adquieren movilidad.

-

Temperatura de fusión (Tm): El punto donde las regiones cristalinas se funden en un estado viscoso.

En el caso de los envoltorios de caramelos, la interfaz de sellado debe ser superior a Tg o acercarse a Tm para permitir la movilidad y la interdifusión de las cadenas poliméricas.

La danza molecular

A temperatura ambiente, las cadenas poliméricas son estáticas. Cuando se calientan:

-

Cadenas desenrollarse y moverse en la interfaz.

-

Cadenas de capas opuestas interdifusoformando enredos.

-

Al enfriarse, las cadenas bloquearse en una estructura cohesiva y monolíticacreando un sello fuerte y hermético.

En los polímeros semicristalinos, la recristalización refuerza aún más la unión, garantizando la frescura y la estabilidad de los caramelos.

Ciencia de los materiales de las películas de caramelo

¿Qué hace que un film sea termosellable?

Una película termosellable debe termoplásticoSe ablandan al calentarse y se solidifican al enfriarse. Los termoestables y los elastómeros no son adecuados.

Polímeros termosellables habituales en el envasado de caramelos

| Polímero | Temperatura de sellado (°C) | Resistencia del sello | Claridad | Key Candy Uso |

|---|---|---|---|---|

| LDPE | 105-150 | Bien | Bien | Bolsas para caramelos en general, envoltorios flexibles |

| LLDPE | 115-160 | Excelente | Bien | Líneas de alta velocidad, requieren adhesivo caliente |

| PP | 160-210 | Bien | Excelente | Bolsas para caramelos de alta calidad, envoltorios rígidos |

| PET | 240-260 | Deficiente (requiere capa de sellado) | Excelente | Capa exterior estructural para películas laminadas de caramelos |

| PVC | 120-180 | Moderado | Excelente | Uso decreciente; a veces para envoltorios de caramelos novedosos. |

| Ionómero (Surlyn®) | 90-130 | Excelente | Excelente | Termosellado por contaminación, paquetes de chocolate de alta calidad |

Arquitectura de película multicapa

Los envases de caramelos suelen utilizar películas coextruidas o laminadas para combinar propiedades:

-

Capa de impresión: Gráficos de alta calidad.

-

Capa de barrera: EVOH o películas metalizadas para evitar la entrada de oxígeno, humedad o luz.

-

Capa de volumen/resistencia: Nylon o PET resistente a la perforación.

-

Capa de corbata: Une polímeros incompatibles.

-

Capa de sellado: Polímero de bajo punto de fusión como el LLDPE o el ionómero para un sellado térmico óptimo.

La Trinidad del Proceso: Temperatura, presión y tiempo de permanencia

La calidad de la foca depende de tres variables interdependientes:

-

Temperatura: Activa la cadena polimérica movilidad. Debe permanecer dentro de la ventana de sellado.

-

Presión: Garantiza un contacto íntimo, elimina el aire atrapado y favorece la interdifusión.

-

Tiempo de permanencia: Duración de la aplicación de calor y presión; permite el enredo completo de la cadena.

Ajustar un parámetro requiere cambios compensatorios en otros. Por ejemplo, mayor velocidad de la línea de caramelos acortar el tiempo de permanencia, necesitando temperaturas de sellado más elevadas.

Tecnologías de termosellado en las líneas de caramelos

| Tecnología | Principio | Materiales adecuados | Velocidad | Coste de capital | Candy Line Uso |

|---|---|---|---|---|---|

| Barra caliente / Contacto directo | Conducción | La mayoría de los termoplásticos | Bajo-Medio | Bajo | Barritas de chocolate, gominolas, bolsitas |

| Inducción | Electromagnético | Tapas de caramelos laminadas | Alta | Medio | Tarrinas herméticas de chocolate, caramelos premium |

| Ultrasonidos | Calor de fricción | Termoplásticos rígidos/semirrígidos | Muy alta | Alta | Blísteres, bandejas de chocolate |

| Aire caliente | Convección | La mayoría de los termoplásticos | Medio-Alto | Medio | Bolsas multicapa para caramelos, formas contorneadas |

Integridad de las juntas y resolución de problemas

Definición de un buen sello

-

Fuerza: Medido mediante pruebas de pelado (ASTM F88).

-

Hermeticidad: Impermeable al aire, la humedad o los microbios (ASTM F1140, F1929).

-

Pelabilidad: Apertura fácil y controlada para los consumidores.

-

Estética: Cierres limpios, uniformes y sin arrugas.

Defectos comunes en los envases de caramelos

| Defecto | Proceso Causa | Causa material | Soluciones |

|---|---|---|---|

| Sello incompleto / Fugas en el canal | Temperatura demasiado baja, intervalo corto, presión desigual | Superficie contaminada, sellador incorrecto | Aumentar la temperatura/dwell, limpiar las mordazas, corregir el material |

| Peeling débil | Temperatura, presión y permanencia insuficientes | Polímeros incompatibles | Ajustar el proceso o utilizar un sellador adecuado |

| Quemaduras / Encogimiento | Temperatura demasiado alta, presión excesiva | Polímero de baja resistencia a la fusión | Bajar la temperatura, reducir la presión |

| Delaminación del sello | Capa de corbata sobrecalentada | Mala laminación, incompatibilidad de tintas | Utilizar capas compatibles, controlar la temperatura |

| Arrugas | Tensión desigual de la película, mordazas desalineadas | Desajuste de la dilatación térmica | Alinear las mordazas, equilibrar la tensión de la película |

Conclusiones: Un enfoque basado en los principios

Dominar el termosellado en la producción de caramelos requiere comprender la ciencia que hay detrás del proceso. Mediante la integración de física de polímeros, transferencia de calor y la trinidad de procesoslos ingenieros pueden:

-

Predecir el rendimiento de las juntas

-

Reducir los defectos y el desperdicio de material

-

Garantice un cierre hermético y uniforme para mayor seguridad y calidad

A enfoque basado en los principios transforma el sellado térmico de una conjetura a un proceso fiable, eficaz y científicamente controlado para producción moderna de caramelos.

- ASTM F88 - Método de prueba de resistencia de sellado para materiales de barrera flexibles https://store.astm.org/f0088_f0088m-21.html

- Normas ASTM de embalaje - Papel y embalaje https://store.astm.org/products-services/standards-and-publications/standards/paper-standards-and-packaging-standards.html

- Ingredientes y envases alimentarios de la FDA https://www.fda.gov/food/food-ingredients-packaging

- Envasado y sustancias en contacto con alimentos (FCS) de la FDA https://www.fda.gov/food/food-ingredients-packaging/packaging-food-contact-substances-fcs

- Wiley Online Library - Materiales de sellado en envases alimentarios de plástico flexible https://onlinelibrary.wiley.com/doi/full/10.1002/pts.2732

- ScienceDirect - Sellado térmico de películas de poliolefina Investigación https://www.sciencedirect.com/science/article/abs/pii/S0142941812001092

- BioResources - Evaluación del termosellado en envases VFFS https://bioresources.cnr.ncsu.edu/resources/heat-sealing-evaluation-and-runnability-issues-of-flexible-paper-materials-in-a-vertical-form-fill-seal-packaging-machine/

- Wiley Online Library - Caracterización del proceso de termosellado https://onlinelibrary.wiley.com/doi/full/10.1002/app.53094

- Normas ISO sobre envases (ISO/TC 122) https://www.iso.org/committee/52040.html

- 21 CFR Parte 211 - Directrices de envasado de productos farmacéuticos https://www.thefdagroup.com/blog/2015/01/overview-of-packaging-guidelines/