Fuente de la imagen: pexels

Cuando digo máquina de galletas, la gente piensa en dos cosas. Algunos ven una gran máquina de alimentos que da forma y hornea galletas. Otros piensan en una herramienta de carpintería que corta ranuras en la madera. Yo quiero hablar de la máquina de la industria alimentaria. Esta máquina es importante porque ayuda a un mercado en crecimiento. El mercado mundial de máquinas para hacer galletas fue de $5,4 mil millones en 2024. Podría alcanzar $8,2 mil millones en 2033. a medida que más gente quiere galletas y aumenta la automatización. Saber cómo funcionan estas máquinas me ayuda a tomar buenas decisiones. Esto es válido tanto si tengo una panadería como si me gusta aprender sobre tecnología alimentaria.

máquina de galletas: Principales conclusiones

Las máquinas de galletas ayudan a hacer galletas más rápidamente realizando muchos pasos. Mezclan, moldean, hornean, enfrían y envasan galletas por sí solas. Elegir la mejor máquina ayuda a hacer más galletas. También ahorra dinero y mejora la calidad de las galletas. Unas buenas herramientas de mezclado y corte ayudan a que las galletas queden bien y tengan siempre un aspecto agradable. Un horneado, enfriado y envasado inteligentes mantienen las galletas frescas y sabrosas. También ayudan a que las galletas sean seguras para el consumo. Las nuevas tecnologías, como la automatización, hacen que las máquinas de galletas funcionen bien. Las funciones de ahorro de energía también facilitan su uso.

Al elegir un máquina de galletas, Considerar el precio es importante para encontrar el mejor valor y maximizar el retorno de la inversión.

¿Qué es un máquina de galletas?

A máquina de galletas es un equipo especializado utilizado en la industria alimentaria para automatizar el proceso de fabricación de galletas. Suele constar de varios componentes, como amasadoras, formadoras, hornos y unidades de envasado, que trabajan conjuntamente para agilizar la producción de galletas. Los principales fabricantes diseñan y fabrican estas máquinas para garantizar la eficacia y la calidad en la producción de galletas. Muchos fabricantes también ofrecen servicios como el diseño de la planta, la instalación, la puesta en marcha y la asistencia posventa continua, incluidos el mantenimiento, la formación y las actualizaciones, para ayudar a los clientes durante todo el proceso de producción.

Fuente de la imagen: pexels

Producción alimentaria máquina de galletas

Cuando entro en una panadería, me fijo en la máquina de hacer galletas. Convierte rápidamente ingredientes sencillos en sabrosas galletas. Esta máquina ayuda a las panaderías a hacer más galletas. Permite a los trabajadores dedicar más tiempo a nuevas ideas y a mejorar el sabor de las galletas.

Una máquina de galletas en la producción de alimentos se compone de muchas partes. Mezcla, moldea, hornea, enfría y envasa galletas. Cada pieza tiene una función especial. Las modernas máquinas de galletas están diseñadas para facilitar la limpieza y el mantenimiento, lo que contribuye a mantener la producción higiénica y eficiente. Al elegir una galletera, es importante comprobar los detalles del producto, como el tamaño, el precio y las características, para asegurarse de que satisface las necesidades de su panadería. A continuación, le explicaré cómo se combinan estas piezas para hacer galletas excelentes en todo momento.

He aquí una tabla que muestra las partes principales y lo que hacen:

|

Componente |

Descripción de la función |

|---|---|

|

Amasadora |

Mezcla ingredientes crudos para crear una masa consistente, garantizando la uniformidad esencial para la calidad de las galletas. |

|

Alimentador de masa |

Transfiere la masa preparada de forma continua y uniforme a la siguiente fase, manteniendo el flujo de producción. |

|

Moldeadora rotativa |

Da forma a la masa en diversos moldes de galletas, lo que permite diseños intrincados y uniformidad. |

|

Máquina cortadora de alambre |

Corta la masa en trozos precisos, especialmente para masas blandas o pegajosas, garantizando la uniformidad de tamaño y grosor. |

|

Horno |

Hornea la masa moldeada con calor controlado para obtener la textura y el sabor deseados. |

|

Transportador de refrigeración |

Enfría las galletas horneadas gradualmente para estabilizar la estructura y evitar la retención de humedad. |

|

Máquinas de embalaje |

Automatiza el envasado y encajado, protegiendo las galletas y prolongando su vida útil. |

|

Máquina sandwichadora |

Aplica rellenos entre las capas de galletas para crear galletas de sándwich con una distribución precisa del relleno. |

|

Máquina decoradora |

Añade toques finales como cobertura de chocolate o glaseado para mejorar el aspecto y la variedad. |

|

Máquina apiladora y contadora |

Organiza las galletas en pilas y las cuenta para envasarlas con precisión. |

El proceso comienza con la amasadora. Mezcla los ingredientes hasta que la masa está lista. El alimentador de masa traslada la masa a la siguiente parte. La moldeadora rotativa o la cortadora de alambre da forma de galleta a la masa. El horno cuece las galletas para que tengan el sabor y el tacto adecuados. Tras la cocción, la cinta de enfriamiento enfría las galletas lentamente. Así se mantienen crujientes y frescas. La máquina de envasado envuelve y embala las galletas. Así se mantienen seguras y sabrosas para los clientes. Algunas máquinas añaden rellenos o decoraciones para hacer nuevos tipos de galletas.

Consejo: Si quiere que su panadería haga más galletas y las mantenga en buen estado, una galletera es una compra inteligente. Ahorra tiempo, reduce el desperdicio y garantiza que todas las galletas sean iguales.

Biscuit Joiner en carpintería

Algunas personas confunden la galletera para alimentos con una herramienta de carpintería llamada engalletadora. La engalletadora no sirve para hornear. Sirve para unir dos piezas de madera. Corta pequeñas ranuras en la madera. Luego coloco una "galleta" ovalada y fina en la ranura. Cuando encolo y sujeto la madera, la galleta se hincha y sujeta las piezas. Esta herramienta sirve para hacer uniones fuertes y ocultas en muebles y armarios.

Si quieres hacer galletas para comer, utiliza una galletera. Si quiere construir muebles, utilice una engalletadora. Conocer la diferencia te ayudará a elegir la herramienta adecuada.

máquina de galletas Operación

Fuente de la imagen: pexels

Cuando veo una máquina de galletas, veo un sistema inteligente. Toma cosas sencillas y hace galletas sabrosas. Cada paso es importante.

Con las galleteras automatizadas, los operarios pueden olvidarse de los pasos manuales que llevan mucho tiempo y centrarse en la calidad y la eficacia.

Si quiere galletas buenas cada vez, debe conocer estos pasos y por qué son importantes.

Mezclar y amasar

Mezclar y amasar son los primeros pasos. Siempre me centro en esta parte porque es muy importante. La batidora adecuada ayuda mucho. Yo utilizo amasadoras horizontales para masas que necesitan un gluten fuerte. Estas amasadoras tienen cuchillas Z, sigma o de pala con rascadores. Mezclan bien y mantienen la masa fría. A veces, utilizo mezcladoras espirales para grandes lotes. Amasan con suavidad y no calientan demasiado la masa. Para lotes pequeños, utilizo batidoras planetarias. El bol se queda quieto mientras la batidora gira. Así se mezcla todo uniformemente.

Estos son algunos de los principales utensilios que utilizo para mezclar y amasar:

-

Mezcladoras horizontales para gluten fuerte y grandes lotes.

-

Amasadoras en espiral para un amasado suave y menos calor.

-

Mezcladoras planetarias para lotes pequeños o medianos.

-

Amasadoras continuas para masas rápidas y uniformes en grandes fábricas.

Siempre compruebo la temperatura de la masa, el agua y la velocidad de amasado. Si utilizo harina con más proteínas, amaso durante más tiempo para conseguir la textura adecuada. El bol contiene la mezcla, la paleta remueve y el gancho amasador amasa hasta que está lista.

Consejo: Si quiere que todas las galletas sepan igual, adquiera una galletera con buenos utensilios de mezcla. Una buena mezcla significa buenas galletas.

Formar y cortar

Después de mezclar, doy forma y corto la masa. Este paso da a cada galleta su forma y tamaño. Las galleteras modernas utilizan tecnología inteligente para ello. Utilizo cortadores giratorios y de vaivén para obtener cortes limpios. Los servomotores me ayudan a conseguir siempre el tamaño correcto, incluso con una precisión de 0,1 mm. Si quiero una forma nueva, cambio las matrices rápidamente. A veces utilizo el corte por ultrasonidos para masas pegajosas. Utiliza vibraciones rápidas para cortar limpiamente y desperdiciar menos masa.

He aquí una tabla con algunos herramientas de conformación y corte Yo uso:

|

Tecnología |

Descripción |

|---|---|

|

Cortadoras rotativas/reciprocantes |

Realiza cortes limpios sin aplastar la masa |

|

Sistemas accionados por servomotor |

Siempre da la talla |

|

Troqueles intercambiables |

Me permite cambiar de forma rápidamente |

|

Corte por ultrasonidos |

Utiliza sacudidas rápidas para cortes limpios |

|

Control inteligente de la presión |

Cambia la presión para diferentes masas |

|

Alimentación automática de masa |

Mueve la masa sin problemas y a tiempo |

|

Interfaces digitales |

Facilita el uso de la máquina |

Si quieres que tus galletas queden perfectas, elige una máquina de galletas con estas herramientas de perfilado y corte.

Horneado y rociado con aceite

Al hornearlas, las galletas adquieren su sabor y su textura crujiente. Pongo el horno entre 200°C y 300°C. Esto hace que las galletas queden crujientes y doradas. Yo utilizo una galletera con buenos controles de temperatura. Incluso un pequeño cambio de temperatura puede estropear las galletas. Vigilo la cocción tiempo para que cada la galleta está en su punto.

Después de hornear, yo rociar las galletas con aceite. Esto hace que brillen y huelan mejor. El aceite les da un bonito color y un rico sabor. Cuando rocío aceite uniformemente, las galletas tienen un aspecto y un olor estupendos. La gente lo nota enseguida.

Nota: Si quieres que tus galletas destaquen, rocía siempre aceite al final. Hará que tus galletas tengan mejor aspecto y sabor.

Refrigeración y envasado

El enfriado y el envasado son los últimos pasos, pero son muy importantes. Si enfrío las galletas demasiado rápido o demasiado despacio, pierden su textura crujiente o quedan empapadas. Yo utilizo una cinta de enfriamiento para que las galletas alcancen lentamente la temperatura ambiente. Así se mantiene la textura adecuada y se evita la pérdida de humedad.

Para el envasado, utilizo materiales que impiden la entrada de aire y agua. Para las galletas con relleno, utilizo un envase especial que mantiene la galleta crujiente y el relleno blando. A veces utilizo envasado en atmósfera modificada. Sustituye el aire del envase por dióxido de carbono. Mantiene las galletas frescas durante más tiempo sin productos químicos adicionales.

Yo siempre guarde las galletas en recipientes herméticoslejos del calor y la luz. Para galletas crujientes, añado capas de papel encerado. Para galletas masticables, pongo una rebanada de pan en el recipiente para mantenerlas blandas. Para las galletas saladas, utilizo paquetes que absorben la humedad.

Si quiere que sus galletas se mantengan frescas y sabrosas, utilice una galletera con un buen sistema de refrigeración y envasado. Sus clientes notarán la diferencia.

Tipos de máquinas de galletas

Cuando elijo una máquina de galletas para mi panadería, me fijo en lo que hace mejor cada tipo. Cada máquina tiene algo especial que puede hacer. Cada tipo de galletera es adecuado para producir distintos tipos de galletas, desde galletas blandas a crujientes crackers. Elegir la máquina adecuada me ayuda a hacer más galletas, ahorrar dinero y mejorar la calidad.

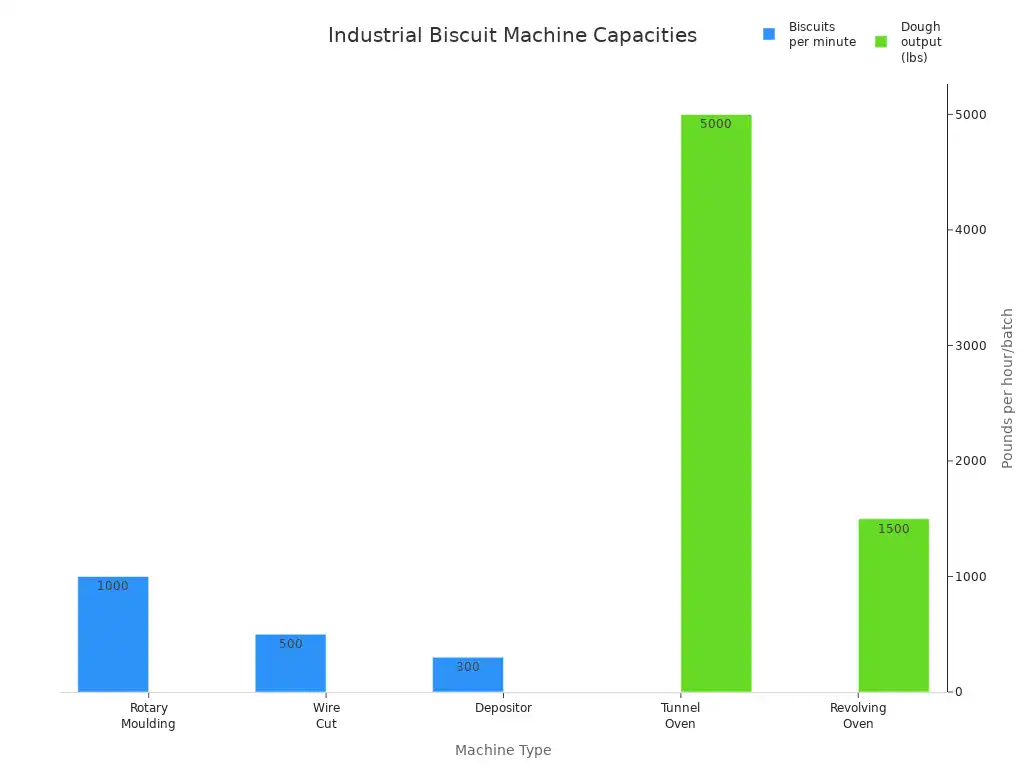

|

Tipo de máquina |

Descripción |

Capacidad/Producción |

|---|---|---|

|

Moldeo rotativo |

Utiliza rodillos para prensar la masa y darle formas detalladas |

Hasta 1000 galletas por minuto |

|

Corte de alambre |

Empuja la masa a través de boquillas, corta con alambre para masas blandas |

Hasta 500 galletas por minuto |

|

Depositor |

Deposita cantidades exactas de masa para galletas rellenas o con forma |

Hasta 300 depósitos por minuto |

|

Horno túnel |

Hornea grandes cantidades con calor uniforme |

Hasta 5000 lbs de masa por hora |

|

Horno giratorio |

Gira las bandejas para un horneado uniforme, ideal para lotes de tamaño flexible |

Alrededor de 1500 libras por lote |

Galletera rotativa

Utilizo máquinas rotativas para galletas cuando necesito trabajar rápido y quiero formas divertidas. Estas máquinas tienen rodillos con moldes especiales que prensan la masa en diseños geniales. Algunas de las máquinas de galletas rotativas más conocidas son de fabricación italiana, famosas por su calidad y durabilidad. Puedo hacer hasta 1.000 galletas por minuto. Me gusta que puedo cambiar los moldes para hacer nuevas formas o añadir palabras. La máquina devuelve la masa sobrante, así que no se desperdicia nada. Las máquinas rotativas son silenciosas y no consumen mucha energía, lo que me permite ahorrar dinero. Con esta máquina puedo hacer shortbread, galletas de mantequilla o incluso golosinas para perros.

Consejo: Si quieres muchas galletas con formas chulas, hazte con una rotativa máquina de galletas.

Máquina de galletas cortadas con alambre

Para masas blandas o pegajosas, utilizo un máquina de galletas cortadas con alambre. Esta máquina empuja la masa fuera de las boquillas y la corta con un alambre. Utilizo una pantalla táctil para elegir la velocidad y la forma. La máquina puede recordar hasta 400 recetas, así que puedo cambiar lo que hago rápidamente. Puedo hacer galletas, magdalenas y diferentes pasteles. Las máquinas de galletas de corte de alambre más pequeñas también son populares para la repostería casera, ya que ofrecen comodidad y resultados profesionales a los cocineros domésticos. El cabezal de corte de alambre se desmonta, por lo que la limpieza es fácil y segura. También puedo cambiar las boquillas y los moldes para probar cosas nuevas.

Máquina depositadora de galletas

Cuando quiero hacer galletas rellenas o especiales, utilizo un máquina depositadora de galletas. Deja caer la cantidad justa de masa o relleno sobre las bandejas. Esto hace que todas las galletas tengan el mismo aspecto y sabor. Puedo rellenarlas con mermelada, nata o chocolate. La máquina trabaja rápido y mantiene las cosas limpias, lo que contribuye a la seguridad alimentaria. Ahorro dinero porque utiliza todo el relleno y necesita menos trabajo del personal. Los controles son sencillos, así que puedo probar nuevos sabores y formas sin reducir la velocidad.

-

Hago galletas más rápido con relleno automático.

-

Cada galleta recibe la misma cantidad de relleno.

-

Puedo hacer muchas formas y utilizar diferentes rellenos.

-

La máquina lo mantiene todo limpio y seguro.

-

Gasto menos dinero en trabajadores y residuos.

-

Unos controles sencillos significan menos tiempo arreglando problemas.

-

Puedo hacer nuevas ideas de galletas rápidamente.

Máquina de embalaje

Después de hornearlas, tengo que envasar las galletas rápidamente y mantenerlas frescas. Las nuevas máquinas de envasado utilizan sensores inteligentes y ordenadores para reducir los residuos y acelerar el proceso. Puedo ver el proceso en directo y solucionar los problemas rápidamente. El diseño me permite cambiar de producto fácilmente. Las galletas rotas o la masa sobrante se reutilizan, lo que ahorra dinero. Estas máquinas consumen menos energía, por lo que mis facturas son más bajas y eso ayuda al planeta. Los sensores de calidad comprueban cada paquete, por lo que los clientes siempre reciben buenas galletas.

Nota: Si quieres que tu negocio crezca, consigue un envasadora inteligente. Desperdiciará menos, empaquetará más rápido y hará felices a sus clientes.

Ventajas de las máquinas de galletas

Eficacia y productividad

Cuando empecé a utilizar máquinas de galletas, hacía más galletas cada día. Las máquinas trabajan mucho más rápido que las personas. Ahora, un técnico puede hacer funcionar una línea que antes necesitaba diez trabajadores. Aquí hay algunas maneras máquinas me ayudan a hacer más galletas:

-

Las líneas automáticas funcionan casi todo el tiempo, así que puedo hacer galletas día y noche.

-

Máquinas mezclar, dar forma, hornear y envasar galletas en un sencillo proceso.

-

Gasto menos dinero en trabajadores porque necesito menos gente.

-

El sistema utiliza menos material y energíaasí que mis costes bajan.

Mi negocio creció porque podía atender pedidos grandes y estar al día de lo que la gente quería. La mejora de la eficiencia y la productividad también ayudó a ampliar las ventas a nuevos mercados y a aumentar los ingresos totales. Gané más dinero y tuve menos errores que corregir.

Consejo: Si quiere que su panadería crezca, adquiera máquinas. Harás más galletas con menos trabajo.

Coherencia y calidad

Quiero que todas las galletas tengan el mismo aspecto y el mismo sabor. Las máquinas me ayudan a hacer bien este trabajo. Miden los ingredientes, mezclan la masa y hornean a la perfección. Esto significa que cada lote es perfecto. Esto es lo que consigo utilizando máquinas:

-

Cada lote se mezcla y hornea de la misma manera.

-

Los sensores comprueban el calor y la humedadpara que las galletas no se quemen ni se empapen.

-

Uso de máquinas piezas de acero inoxidable aptas para alimentos.

-

Los sistemas de control de calidad detectan los problemas antes de que las galletas salgan de la fábrica.

Mis clientes confían en mi marca porque siempre reciben las mismas galletas buenas.

Seguridad e higiene

La seguridad alimentaria es muy importante para mí. Las máquinas modernas facilitan la limpieza y la seguridad. Utilizo equipos de acero inoxidable liso y piezas desmontables. Esto me ayuda a limpiar rápido y evita que crezcan gérmenes. Aquí tienes una tabla con algunos características importantes:

|

Categoría |

Características específicas |

Objetivo/Beneficio |

|---|---|---|

|

Diseño higiénico |

Superficies fáciles de limpiar, acero inoxidable, piezas desmontables, ciclos de limpieza automáticos |

Detenga las bacterias y mantenga los alimentos seguros |

|

Características de seguridad |

Botones de parada de emergencia, protectores de seguridad, apagado automático |

Garantizar la seguridad de los trabajadores y de las máquinas |

|

Mantenimiento |

Piezas fáciles de desmontar |

Limpieza rápida y menos tiempo parado |

Estoy seguro de que mis galletas son seguras para todos.

Tendencias e innovaciones

Automatización y controles inteligentes

La automatización está cambiando la forma de hacer galletas. Ahora los robots mezclan, cortan, hornean y envasan galletas. Estas máquinas trabajan con rapidez y no se cansan. Sensores y programas inteligentes vigilan cada paso. Si algo va mal, recibo un aviso enseguida. Puedo solucionar los problemas antes de que la máquina se pare. La IA me ayuda a saber si una pieza podría romperse pronto. Puedo solucionarlo pronto y evitar parar la línea. Con los controles inteligentes, veo cuánto uso y a qué velocidad trabajo. Desperdicio menos y siempre hago buenas galletas.

El uso de la automatización ahorra dinero en mano de obra y reduce los errores. Mis galletas siempre tienen el mismo aspecto y sabor. Los trabajadores pueden hacer trabajos creativos, como elaborar nuevas recetas.

He aquí algunas formas automatización y controles inteligentes Ayuda:

-

Los robots hacen trabajos duros o arriesgados y mantienen a salvo a las personas.

-

Sensores y cámaras comprueban cada galleta en busca de problemas.

-

IA e IoT me permiten ver y cambiar las cosas desde cualquier lugar.

-

El envasado automatizado es más rápido y mantiene seguras las galletas.

Eficiencia energética

Ahorrar energía es muy importante para mí. Las nuevas máquinas utilizan IA y sensores para ahorrar hasta la mitad de energía. Yo uso hornos que cambian el calor en función de la masa y la humedad del aire. Sistemas de recuperación de calor aprovechar el calor extra y volver a utilizarlo. Esto reduce mis facturas. Utilizo motores que cambian de velocidad, así que sólo consumo la energía que necesito. Algunas fábricas utilizan paneles solares para hacer funcionar sus máquinas. Estos cambios ayudan al planeta y ahorran dinero.

|

Función de ahorro de energía |

Beneficio |

|---|---|

|

Sensores de IA e IoT |

Menos derroche de energía |

|

Sistemas de recuperación de calor |

Menores costes operativos |

|

Hornos inteligentes |

Cocción precisa, menos energía |

|

Motores eficientes/VFD |

Utilizar sólo la electricidad necesaria |

Personalización

Los clientes quieren nuevos sabores, formas y opciones saludables. Yo utilizo máquinas con moldes y ajustes que puedo cambiar. Puedo pasar de las galletas redondas a las de estrella en cuestión de minutos. También puedo hacer galletas sin gluten o veganas. Esto me permite seguir las tendencias rápidamente. No necesito máquinas nuevas para cada producto. La personalización me ayuda a conseguir más clientes y destacar.

Si quiere que su negocio crezca, elija máquinas que le permitan fabricar nuevos productos con rapidez. Siempre irá por delante de los demás.

Sé que tener la máquina adecuada puede ayudar mucho a mi panadería. Cuando elijo una máquina, pienso en varias cosas. Miro la tamaño de las galletas que quiero hacer. También compruebo cuántas galletas tengo que hacer cada día. Decido qué tipo de galletas quiero hacer. Pienso con qué frecuencia hay que arreglar o limpiar la máquina. Me aseguro de que tengo espacio suficiente en mi panadería para la máquina. Compruebo si la máquina tiene piezas de seguridad para mantener a salvo a mi equipo. También miro cuánta energía consume y si hay un plan de reserva.

Nuevas herramientas como Impresión 3D, corte por ultrasonidos, y controles inteligentes me ayudan mucho. Me permiten hacer galletas con nuevas formas y sabores. Estas herramientas también me ayudan a ahorrar energía. Si quieres que tu panadería crezca, habla con gente que conozca estas máquinas. Deberías analizar todas las opciones antes de decidirte.

Preguntas más frecuentes

¿Cuánto cuesta un máquina de galletas ¿Costes?

Las galleteras pequeñas cuestan alrededor de $5.000. Muchas máquinas de galletas se fabrican en China, que es conocida por ofrecer una amplia gama de opciones a precios competitivos. Las máquinas grandes y automáticas pueden costar más de $100.000. Creo que es inteligente comprar una buena máquina. Una máquina de calidad ahorra tiempo y ayuda a ganar más dinero.

¿Puedo hacer distintos tipos de galletas con una sola máquina?

Sí. Mis máquinas tienen moldes y ajustes que puedo cambiar. Puedo hacer nuevas formas, tamaños y recetas rápidamente. Esto me ayuda a dar a los clientes lo que quieren y a seguir las nuevas tendencias.

¿Es difícil limpiar una galletera?

La limpieza de las máquinas nuevas es sencilla. Se recomienda realizar revisiones periódicas para mantener la máquina limpia y en buen estado de funcionamiento. Puedo desmontar piezas rápidamente y utilizar ciclos de limpieza. Las máquinas limpias mantienen las galletas seguras y sabrosas. Siempre leo las instrucciones para limpiar correctamente.

¿Las máquinas de galletas mejoran realmente la calidad del producto?

Pues sí. Muchos fabricantes ofrecen asistencia continua para ayudar a las panaderías a mantener la alta calidad de sus productos. Las máquinas mezclan, moldean y hornean siempre de la misma manera. Cada galleta tiene el mismo aspecto y el mismo sabor que la anterior. Mis clientes lo ven y confían en mis galletas.

¿Qué mantenimiento necesita una galletera?

Examino las piezas móviles, limpio la máquina y cambio las piezas viejas. Muchos fabricantes ofrecen asistencia de por vida, que incluye reconstrucciones periódicas y formación para que su equipo se asegure de que la máquina funciona de forma óptima. Hacer esto a menudo hace que mi máquina siga funcionando bien. Sigo un plan y utilizo las piezas adecuadas. Esto evita problemas y ahorra dinero.