Introducción a la producción de galletas

- Una línea de producción de galletas se compone de varias máquinas y equipos diseñados para producir galletas a gran escala, como la línea de producción de galletas blandas y la línea de producción de galletas duras.

- La línea de producción garantiza una calidad uniforme, reduce los residuos y aumenta la productividad en la producción de galletas.

- Las líneas de producción de galletas pueden producir diversos tipos de galletas, como galletas de masa dura y galletas blandas.

- El proceso de producción de galletas consiste en mezclar, moldear, hornear y envasar galletas de forma eficiente y en grandes volúmenes. El proceso comienza con la preparación de la masa de galletas, en la que se utilizan mezcladoras para crear una masa mezclada uniforme, esencial para obtener una calidad uniforme en todos los tipos de galletas.

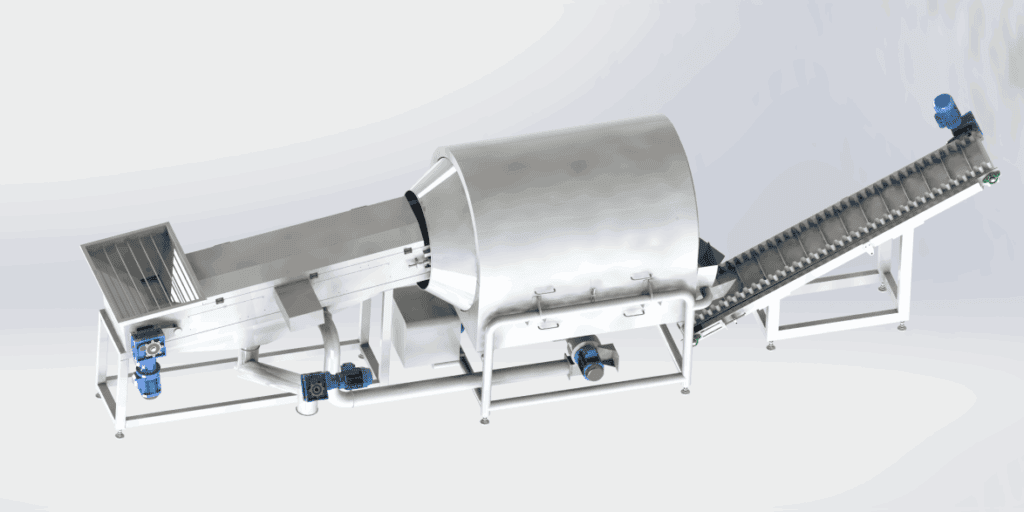

- Los componentes clave de una línea de producción son la amasadora, la cortadora rotativa y el horno túnel. Las máquinas modernas automatizan casi todas las fases de la producción de galletas, desde la preparación de la masa hasta el envasado, lo que garantiza la eficacia y la uniformidad.

Componentes clave de un Línea de producción

En el proceso de formación de una línea de producción de galletas intervienen equipos de formación de masa como una moldeadora rotativa y un proceso de laminación. Durante esta fase, la sal y el azúcar pueden espolvorearse o esparcirse sobre la superficie de la masa utilizando espolvoreadores o esparcidores especializados en sal y azúcar para realzar el sabor y el aspecto de las galletas.

Los hornos de túnel se utilizan para hornear las galletas, lo que garantiza una cocción uniforme y la textura y el crujiente deseados, además de una calidad constante del producto y una buena relación coste-eficacia.

Se utiliza un sistema de alimentación y un transportador para transportar la galleta horneada a la siguiente máquina de la línea de producción.

Las máquinas de envasado se utilizan para envasar el producto final, reduciendo los costes de mano de obra y los errores humanos.

Existen opciones de personalización para adaptarse a las necesidades específicas de producción de galletas.

Línea de producción de galletas

Una línea de producción de galletas es un sofisticado sistema diseñado para producir galletas de alta calidad a gran escala, combinando maquinaria avanzada y procesos precisos para obtener resultados óptimos. En esencia, la línea de producción consta de componentes clave como la amasadora, la cortadora rotativa, el horno túnel y las máquinas de envasado, que trabajan en armonía para agilizar la producción de galletas y garantizar una calidad constante del producto.

La línea de producción de galletas duras está diseñada específicamente para la fabricación de galletas de masa dura, incluidas variedades populares como las galletas de nata y las petit beurre. Esta línea utiliza un proceso de laminación para estratificar la masa, creando la textura ligera y crujiente característica de las galletas duras. La cortadora rotativa da forma a la masa en trozos uniformes, mientras que el horno de túnel los hornea a la perfección, dando como resultado galletas duras con un sabor y una textura uniformes. Todo el proceso está diseñado para maximizar la capacidad de producción y la eficiencia, por lo que es ideal para la producción de galletas a gran escala.

Para las galletas blandas, la línea de producción de galletas blandas emplea equipos especializados como la moldeadora rotativa, que moldea suavemente la masa blanda en una variedad de formas, incluidas las galletas de mantequilla y las galletas de sándwich. A continuación, el horno de túnel hornea estas galletas moldeadas, garantizando una textura tierna y fundente. Esta línea está optimizada para producir galletas blandas de calidad y sabor uniformes, atendiendo a las diversas preferencias de los consumidores.

Los sistemas de transporte, como el transportador de enfriamiento, desempeñan un papel crucial en el proceso de producción al transportar eficazmente las galletas horneadas a través de cada etapa, desde el horno hasta el envasado. Estos sistemas ayudan a mantener la integridad y frescura de las galletas al tiempo que minimizan la manipulación manual y los costes de mano de obra. Las máquinas de envasado mejoran aún más la eficiencia de la producción al automatizar el proceso de envasado, ofreciendo flexibilidad en formatos de envasado como bolsas, cajas y bandejas.

Las opciones de personalización son un sello distintivo de las modernas líneas de producción de galletas, ya que permiten a los fabricantes adaptar el sistema a sus necesidades específicas, ya sea aumentando la capacidad de producción, mejorando la eficiencia de la producción o adaptándose a nuevos tipos y formas de galletas. La integración de la última tecnología, incluidos equipos avanzados como el pulverizador de huevos y el apilador de rueda de estrella, garantiza una alta precisión, reduce los errores humanos y favorece la calidad uniforme del producto en todos los lotes.

En resumen, una línea de producción de galletas bien diseñada es esencial para la fabricación eficiente de galletas a gran escala. Al aprovechar las máquinas de última generación y un proceso de producción sin fisuras, los fabricantes pueden producir una amplia gama de galletas duras y blandas con un sabor, una textura y un aspecto superiores, todo ello optimizando los costes de mano de obra y manteniendo altos niveles de calidad.

Galletas de masa dura

Las galletas de masa dura se elaboran con masa fermentada laminada y cortada antes de hornearla.

Los productos más populares son las galletas de nata, las petit beurre y otros tipos de galletas duras de textura ligera y larga conservación. Las líneas de producción de galletas duras también pueden producir variedades recubiertas de chocolate, lo que amplía la gama de productos y satisface las preferencias de los consumidores.

La producción de galletas duras implica un proceso específico que incluye la mezcla, el corte y el horneado.

La capacidad de producción y la eficiencia productiva de las galletas de pasta dura pueden mejorarse con los equipos y máquinas adecuados.

Las galletas de masa dura pueden producirse en varias formas y tamaños utilizando una cortadora rotativa y otros equipos de formación de masa, y la forma desempeña un papel crucial en la creación de galletas uniformes y visualmente atractivas.

Fabricación a gran escala

- La fabricación de galletas a gran escala requiere una gran precisión línea de producción de galletas.

- La línea de producción debe diseñarse específicamente para la producción de galletas, teniendo en cuenta factores como el tiempo de cocción y la temperatura del horno.

- Una línea de producción de galletas a gran escala puede producir un gran volumen de galletas por hora, lo que la hace ideal para la producción comercial de galletas.

- La línea de producción puede equiparse con la tecnología más avanzada, incluidas máquinas que automatizan el proceso de elaboración de galletas.

- Existen opciones de personalización para adaptarse a las necesidades específicas de fabricación a gran escala.

Soluciones para la elaboración de galletas

- Las soluciones de fabricación de galletas implican el uso de máquinas y equipos diseñados para producir galletas a gran escala.

- Las soluciones incluyen una línea de producción de galletas blandas y otra de galletas duras, así como equipos para mezclar, moldear, hornear y envasar.

- Las soluciones de fabricación de galletas pueden personalizarse para adaptarse a las necesidades específicas de producción de galletas, incluida la producción de galletas saladas y pasteles.

- Las soluciones pueden ayudar a mejorar la eficiencia de la producción y reducir los costes laborales.

- Las soluciones para la fabricación de galletas también pueden ayudar a mejorar la calidad y la textura del producto final.

Optimización del proceso de producción de galletas

- La optimización del proceso de producción de galletas implica el uso de máquinas y equipos diseñados para mejorar la eficiencia de la producción y reducir los costes de mano de obra.

- El proceso de optimización puede ayudar a mejorar la calidad y la textura del producto final.

- La optimización del proceso de producción de galletas puede adaptarse a las necesidades específicas de producción de galletas, incluida la producción de galletas blandas y galletas de masa dura.

- El proceso de optimización puede implicar el uso de una amasadora, un cortador giratorio y un horno de túnel.

- La optimización del proceso de producción de galletas también puede implicar el uso de máquinas de envasado y otros equipos.

Mantenimiento y actualización

- El mantenimiento y la modernización de las líneas de producción de galletas son esenciales para garantizar la calidad constante del producto y la eficiencia de la producción.

- Un mantenimiento regular puede ayudar a reducir el tiempo de inactividad y mejorar el rendimiento general del línea de producción.

- Se pueden realizar actualizaciones para mejorar la capacidad de producción y la eficacia de la línea.

- El mantenimiento y la modernización también pueden implicar la sustitución de piezas desgastadas y la instalación de nuevas máquinas y equipos.

- Existen opciones de personalización que se adaptan a las necesidades específicas de mantenimiento y actualización.

Sociedad Americana de Panadería (ASB) https://asbe.org/

BEMA - Fabricantes de equipos de panadería y afines https://www.bema.org/

Asociación Americana de Panaderos (ABA) https://americanbakers.org/

Reading Bakery Systems – Industrial Baking Equipment https://www.readingbakery.com/

Revista Baking Business https://www.bakingbusiness.com/

Commercial Baking – Industry News & Resources https://commercialbaking.com/

PMMI – Packaging and Processing Equipment https://www.pmmi.org/

Revista Snack Food & Wholesale Bakery https://www.snackandbakery.com/

AIB International - Ciencia y Tecnología de la Panificación https://www.aibinternational.com/

Society of Bakery Women https://bakerywomen.org/