Quiénes somos

Acerca de Junyu

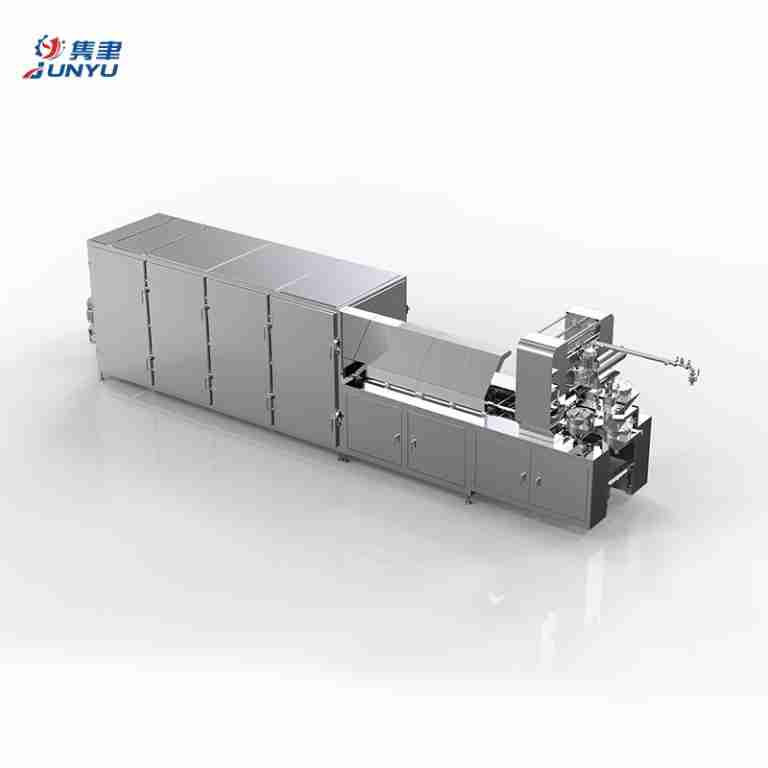

Junyu es un fabricante profesional de equipos alimentarios, tales comomáquinas para hacer galletas, Línea de producción de pastelesGominolas de caramelo, Línea de producción de gomitasLínea de producción de galletas, equipos para aperitivos, etc. Hemos estado en esta línea durante más de 30 años. Nuestros productos se venden bien en todo el mundo y gozan de una buena reputación entre nuestros clientes.

Nuestra empresa ha superado la certificación del sistema de gestión de calidad ISO9001:2008, y también somos una de las empresas centrales de la Asociación de la Industria de Equipos de Preparación de Alimentos de China (CFPEA).

Queremos entablar amistad con usted a través de nuestros productos de alta calidad y nuestro servicio sincero.

Categorías de productos

02.

02. Línea de producción de caramelos

03.

03. Línea de producción de chocolate

04.

04. Máquina envasadora de alimentos

05.

05. Línea de producción de boba

06.

06. Línea de producción de pasteles

Junyu

Nuestros servicios

Fabricación de equipos alimentarios de alta calidad

Junyu se especializa en el diseño y fabricación de equipos para alimentos de primer nivel, incluyendo sistemas para caramelos de goma, líneas de producción de galletas, maquinaria para pasteles y equipos para snacks. Con más de 30 años de experiencia en el sector, nos aseguramos de que cada producto que entregamos cumpla con los más altos estándares de calidad y eficiencia.

Distribución mundial y reputación

Nuestros equipos alimentarios gozan de confianza y se venden en todo el mundo, lo que nos ha granjeado una sólida reputación de fiabilidad e innovación. No importa dónde se encuentre, Junyu garantiza que nuestros productos satisfacen las necesidades de los clientes de diferentes regiones, ofreciendo una calidad y un rendimiento constantes.

Gestión de calidad con certificación ISO9001:2008

Junyu se compromete a mantener los más altos niveles de excelencia en la fabricación. Desde los equipos para gominolas de caramelo hasta nuestros avanzados sistemas de líneas de producción de galletas, todos los productos están certificados según el sistema de gestión de calidad ISO9001:2008, lo que garantiza una fabricación de precisión y un rendimiento duradero.

Asistencia integral al cliente

Nos dedicamos a proporcionar un servicio de atención al cliente excepcional. Desde la consulta preventa hasta la asistencia postventa, nuestro equipo de Junyu está siempre dispuesto a ayudarle en cada paso de su viaje de compra. Tanto si necesita asistencia técnica como orientación sobre el uso del producto, estamos aquí para ayudarle.

Liderazgo y colaboración en el sector

Como una de las empresas centrales de la Asociación China de la Industria de Equipos de Preparación de Alimentos (CFPEA), Junyu desempeña un papel activo en la configuración de la industria de equipos alimentarios. Colaboramos con otros líderes del sector para garantizar que nuestros productos no solo sean innovadores, sino que también se ajusten a las últimas normas y tendencias del sector.

Soluciones a medida para su empresa

Entendemos que cada negocio tiene unas necesidades únicas. Junyu ofrece soluciones personalizadas de equipos alimentarios adaptados a sus requisitos de producción específicos. Tanto si busca un sistema para caramelos de goma, una línea de producción de galletas, una máquina para pasteles o un equipo para aperitivos, nuestro equipo de expertos trabajará con usted para crear la solución perfecta para sus operaciones.

Junyu

Máquina de caramelos de goma y máquinas de línea de producción de galletas

Operación simple Precio razonable Ajuste de temperatura Servo depósito PLC ajustable...

Al integrar tecnología avanzada y procesos racionalizados, esta línea ayuda...

Junyu

Nuestros clientes

Junyu

Últimas noticias

- 12345678...9101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384