Essential Insights on Biscuit Production Line Efficiency and Design

Introduction to Biscuit Production

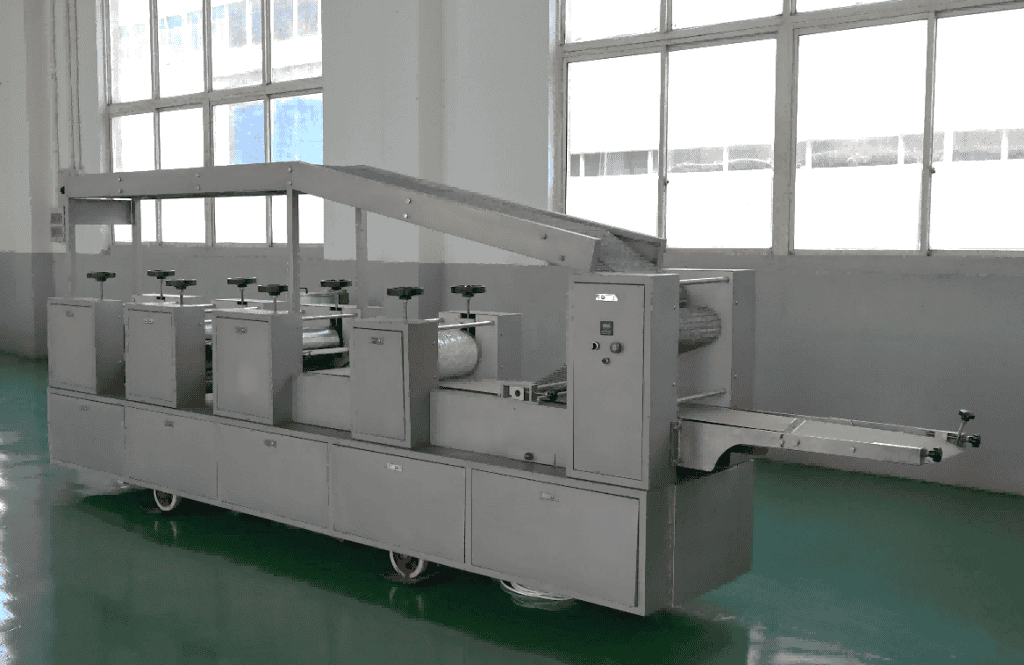

A biscuit production line consists of various machines, such as dough mixers, forming machines, and ovens, which are essential components designed to produce biscuits on a large scale. A company with expertise in biscuit production lines can provide customized solutions and technical support to meet specific production needs.

The food processing industry relies on efficient biscuit production lines to ensure consistent product quality. Cost efficiency is a major advantage of modern biscuit production lines, achieved through automation and resource optimization.

Biscuit production lines can be customized to produce different types of biscuits, including soft dough biscuits and hard biscuits.

Leading manufacturers in the industry provide state-of-the-art machinery and equipment for biscuit production.

Key Components of a Biscuit Production Line

- A typical biscuit production line includes a dough mixer, tunnel oven, and packaging machines.

- The dough mixer ensures the biscuit dough is well-blended and consistent before it moves to the next stage.

- The production line is designed to automate the biscuit making process, reducing manual labour and human errors.

- Key components of a biscuit production line include the conveyor belt, which plays a crucial role in moving biscuit dough through the various stages of mixing, shaping, and baking, as well as cooling conveyors and automated systems.

- Specialized machinery, such as rotary moulders, is used to produce specific types of biscuits.

Biscuit Making Process

- The biscuit making process involves producing biscuits through steps such as mixing, dough forming, and baking.

- Selecting and preparing high-quality raw materials is crucial for achieving optimal biscuit quality.

- Tunnel ovens are used for mass production of biscuits, ensuring consistent baking time and temperature.

- The production process can be customized to produce different types of biscuits, including sandwich biscuits and crackers.

- Efficient production lines can reduce labor costs and increase production efficiency.

Types of Biscuit Production

- Soft biscuit production lines are designed to produce soft dough biscuits, while hard biscuit production lines produce hard biscuits. Soft biscuits typically have a higher fat and sugar content, which, combined with specific baking techniques, results in a tender and soft texture.

- Cookie production lines are similar to biscuit production lines but are designed specifically for cookie production.

- Cracker production lines are used to produce crackers and other types of baked goods.

- Biscuit production lines can be customized to produce a variety of biscuit types.

Large Scale Production

- Large scale production requires efficient biscuit production lines that can produce high volumes of biscuits.

- Complete lines, including production line manufacturer equipment, are designed to meet specific production requirements.

- Higher quality biscuits can be produced using state-of-the-art machinery and equipment.

- Leading manufacturers in the industry provide machinery and equipment for large scale biscuit production.

Production Line Design

- Production line design is critical to ensuring efficient biscuit production.

- Key factors in production line design include working width, production capacity, and customization options.

- Machines automate the biscuit making process, reducing manual intervention and increasing production efficiency.

- Production line design should take into account specific production requirements, including the type of biscuits being produced.

Hard Dough Considerations

- Hard dough biscuits require specialized machinery and equipment, including rotary moulders.

- Hard biscuit production lines are designed to produce high volumes of hard biscuits.

- Key factors in hard dough biscuit production include dough mixer, baking oven, and cooling conveyor.

- Production line design should take into account the specific requirements of hard dough biscuit production.

Key Factors in Production

- Key factors in biscuit production include production efficiency, product quality, and reduced labor costs.

- Critical components of a biscuit production line include conveyor belts, tunnel ovens, and packaging machines.

- Additional equipment, such as dough mixers and rotary moulders, can be added to the production line to increase efficiency.

- Production line design should take into account the specific requirements of the production process.

Production Line Layout

- Production line layout is critical to ensuring efficient biscuit production.

- Key factors in production line layout include working width, production capacity, and customization options.

- Machines should be arranged to minimize manual intervention and increase production efficiency.

- Production line layout should take into account specific production requirements, including the type of biscuits being produced.

Streamlining Production

- Streamlining production involves optimizing the production process to increase efficiency and reduce waste.

- Key benefits of streamlining production include reduced labor costs, increased production efficiency, and higher quality biscuits.

- Production line design should take into account the specific requirements of the production process.

- Machines and equipment should be designed to automate the biscuit making process, reducing manual intervention.

Maintenance and Quality Control

- Maintenance and quality control are critical to ensuring consistent product quality.

- Regular maintenance of machinery and equipment is necessary to prevent breakdowns and reduce downtime.

- Quality control measures, such as inspection and testing, should be implemented to ensure high quality biscuits.

- Production line design should take into account the specific requirements of maintenance and quality control.

Packaging and Distribution

- Packaging and distribution are critical components of the biscuit production process.

- Packaging machines should be designed to handle specific types of biscuits, including sandwich biscuits and crackers.

- Distribution channels should be established to ensure timely delivery of biscuits to customers.

- Production line design should take into account the specific requirements of packaging and distribution.

Conclusion

A well-designed biscuit production line is the foundation of efficient and high-quality biscuit production in the modern food processing industry. By integrating advanced machinery and automated systems, companies can streamline every stage of the production process—from mixing and dough forming to baking in tunnel ovens and final packaging. This approach not only ensures consistent product quality but also maximizes production capacity and reduces labor costs, which are critical factors for success in large scale biscuit production.

Selecting the right equipment and working with a reputable production line manufacturer are essential steps in building an efficient biscuit production line. Leading manufacturers offer state-of-the-art machinery and complete lines tailored to specific production requirements, whether the goal is to produce soft dough biscuits, hard biscuits, crackers, or sandwich biscuits. Specialized machinery, such as rotary moulders and automated packaging machines, further enhances production efficiency and allows for the creation of a wide variety of biscuit types to meet diverse market demands.

Automation and control systems play a pivotal role in reducing human errors and minimizing waste, resulting in higher quality biscuits and more cost-efficient operations. By customizing production lines to match specific production needs—such as a soft biscuit production line for soft dough biscuits or cookie production lines for cookies—companies can achieve greater flexibility and respond quickly to changing consumer preferences.

In the competitive biscuit production business, investing in the right equipment and focusing on key components like conveyor belts, tunnel ovens, and cooling conveyors can make a significant difference in product quality and operational efficiency. Companies that prioritize efficient production processes and leverage the latest technology are better positioned to produce biscuits at scale, maintain consistent product quality, and meet the evolving demands of the food industry.

Ultimately, the success of any biscuit production operation depends on a thoughtful approach to production line design, equipment selection, and process optimization. By embracing state-of-the-art solutions and working closely with leading manufacturers, companies can build efficient biscuit production lines that deliver higher quality biscuits, reduce costs, and drive long-term growth in the food processing industry.